Thanks for coming in, Jeff. As usual, you got me thinking. Buckle up, I’m rambling (and maybe learning) again. I’m sure we’ve got a member or three that studied something relevant to all this and can correct me, but here goes.

That’s basically what I’m getting at (re fans). I have a cnc or two to make all those holes for me. My mental model of fluid says the biggest hole I need is the size of the fan, and the smallest hole I need is only a little bit smaller unless I want to live with restrictions. If I’m only going to get half the airflow because of a filter, maybe I need something less than half the cross section for a hole, but I don’t know how much less (it may even be 0 less).

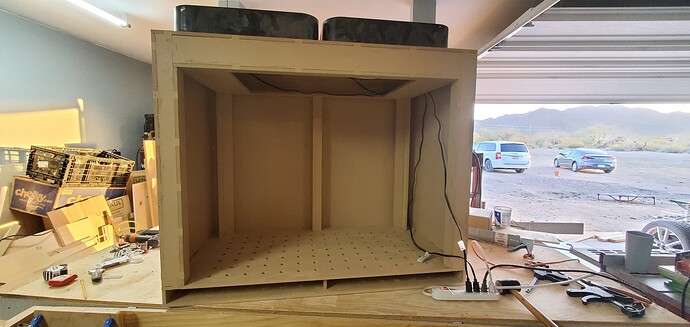

But I’m not trying to suck up dust. I’m just trying to create a draft table, vs a suction table. I really don’t think strong suction is necessary for this, and higher volume is better. (I think I found the rub near the end of this post).

I used a box fan to collect the powder coat overspray from a quick cabinet I made. You may or may not remember pictures of something I posted demonstrating why a guy like me needs a cnc, because the cabinet was pretty rough compared to a spray paint shelf i cnc’d, lol.

At any rate, it did a great job at that. The fan was pointed out the back, slightly above the work (space constraints) maybe 18 inches away from the coater with a wide open front, and had a large opening for the fan, covered by a pretty good filter. I’d used a cheap one at first, but it let too much through and pretty well wrecked the fan. Even stuck at low speed with a better filter, it did a good enough job that we still used it, so the fans DO have some pressure.

I figure for a downdraft table specifically for sanding, gravity is going to do a lot of the work. I only occasionally use an angle grinder. Most of it is a palm sander, followed by hand sanding, then dremel, then belt. Maybe we can classify dust into two categories : heavy enough to be significantly affected by gravity, and everything else. Each might get ejected at speed from or by a machine, or not so much, and basically all hand sanding would be slow dust.

Heavy slow dust will land on the table without much help, but the better the flow(down), the less it will travel.

Heavy fast dust needs high flow the most, but will settle to the floor (and other things) quickly where it will be swept, wiped, or vacuumed up.

Light fast dust will probably slow down quickly because momentum vs air resistance, and be more likely to catch a draft into the table.

Light slow dust will be most likely captured, as long as there is any draft at all close to it.

Learning starts here:

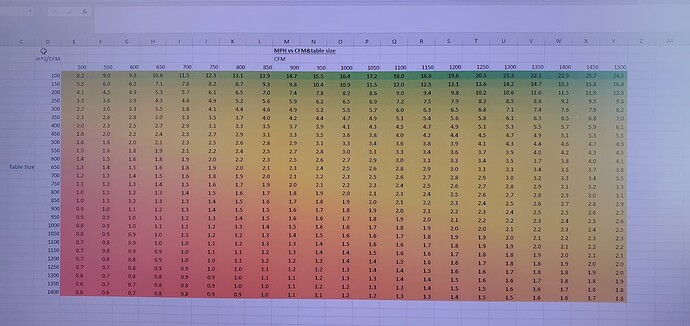

I double checked the listing for my actual fans and they claim 2300 cfm. But suppose I’m wrong about losing half the airflow. Maybe it’s actually closer to 75%, even, with a good filter, and they start out at 2k in the real world. Then for a pair of 20x20 fans at 500cfm each, if I can give 200 sq inches of holes (2x20x20x(1-0.75)) in a 1400 sq inch table, then the table top wouldnt be an EXTRA restriction. If I’m wrong and the filters are only only a reduction by half, maybe I need 400 sq in of holes. Either way, i think if there aren’t enough holes, the fans bog down way before air velocity goes up (and I don’t think it ever actually goes up, honestly), reducing effectiveness. If I have too many, the air moves somewhat slower than it might, reducing effectiveness.

I think that’s where the dust collector wins. Maybe not because of the actual extra power it has, but because the extra power means i don’t have to be so precise on the calculation. Does that make sense?

Added bonus, turning the fans into scrubbers means they don’t have to be in the same spot and can work in addition to the draft table.