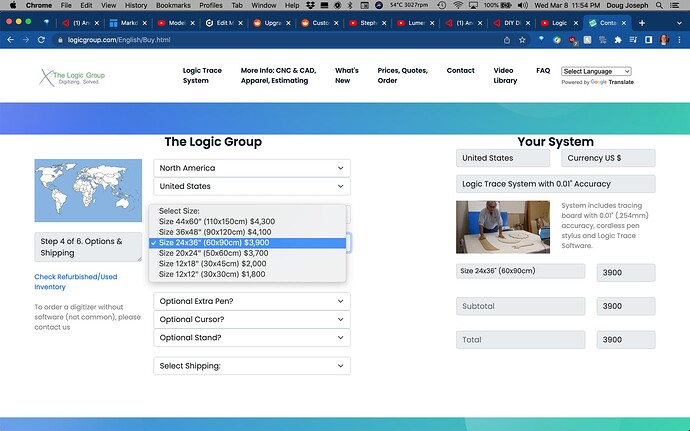

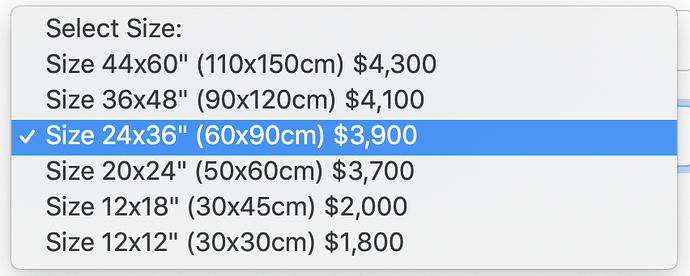

Wow that thing must be expensive!!! Way too easy!

Tracing a flat pattern isn’t a problem. These panels are molded from fiberglass and while the portion of the panel facing the pilot is flat, the areas behind the panel can be quite a bit different than the exposed flat instrument mounts. Please look at the photo of the collection of panels I posted above. I have only cut two panels that were simple and flat.

Thanks for all the suggestions,

Mike B.

Cheers Mike, yes I understand that -(I figured the how-to might be of use for someone tripping over this thread in the future) .

The bit I’m missing is what you are doing with those mounts. if you are just trying to get clearance for the instruments won’t a relatively quick “extrusion” create the envelope of the volume you need to work within? Would a simple 3d scanning app be good enough for that?

I’m coming from a boat building world where nothing is flat and to be fair probably not precise either, but before all this fancy digital stuff we’d just whack out a negative template in cardboard or foam or anything that was easy to work with and measure from that.

An extrude of each individual instrument, mounted in the panel, would show the extent of the area behind the panel.

Again with the sides of the panel often tapering inward toward the instruments (and maybe even outward as well, in the same part) and the back edges of the molded part are not necessarily parallel to the front, I end up with a very non-linear edge that may not have a clear relationship to the front of the panel.

Fortunately, most of the panels I cut are not as convoluted as I have described!

Mikeb.