That would be awesome to show off the jackpot at a show or reprap festival.

That really shouldn’t happen, looks like the prints my Mini made. I built a shelf that is bolted to the wall and would only move if the wall moved.

But forgiveness is not easily given at all times.

Unless your printer’s frame is loose, table shake has very little to do with print quality. Like almost zero.

Doing a little reading on the subject this morning.

Maybe one interesting thread for reference: CO2 laser with four mirrors

My overall research indicates that there will be “some” effect, but it will depend on the quality of mirrors.

There are no perfect mirrors, but the quality will determine how much energy they absorb. This absorption of energy also affects the life of the mirrors and how often they need to be replaced.

Seems like 2-3% loss per mirror is a common number I keep seeing. I’m guessing mirrors of higher quality and less loss might break the budget.

My gut says that’s not enough to be concerned over given the power of tube you plan on buying, but it will make alignment a little more tedious, and the build/maintenance a little more costly.

You could also stick with 3 mirrors, but that means you have to make your X the across the 1200mm length instead of the 600mm length.

This playlist is of a Y-400 build, and it’s oriented the way you want, with a much smaller span, of course.

90W Laser Cutter From Scratch: A.C. Wright

Yeah the mirrors are going to be a PITA no matter what. With the size tube I’m planning on I don’t see it being on the side being an issue. But if I ever upgrade to a better tube later most of the ones I’ve seen are 200mm longer. That will be a problem then. And I definitely don’t want to make X the long axis. Decisions decisions lol

Ok let me ask this. What mirrors does everyone suggest?

Here’s another build. One of the only build series I can find that isn’t from FF.

However, he says everything is available, but I have not been successful in finding any of the files

Edit: Finally found it https://github.com/stevemakeseverything/designs/tree/master/Other/0070

Nowhere near the kind of doc quality as FF, but a good reference as well for a rear mounted tube design. But no Fusion model that I can find

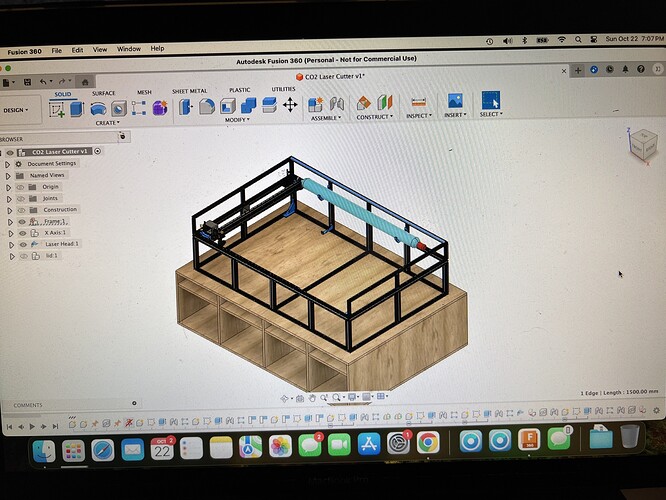

Watching it now. And he shows a real nice fusion cad model. Sucks you can’t download that.

Found it…

https://www.bytesizedengineering.com/store/co2-laser-cutter-fusion-360-design-and-step-files

Ok I know you downloaded it. Was it worth $16??

Just read the link. He says it’s parametric so that would be a huge plus if fusion lets it work correctly lol

I didn’t.

But maybe that was actually the one I was thinking of where he had it fully assembled and was testing the motion in Fusion, not FF.

Ok. I will download it here later and check it out. Trying to get my old mac book to act right lol. Sucks not having my good computers at the house lol

I find that is most of it firme. I have not used my mpcnc nearly as much as i should have!!!

I do end up using them a bunch. But here lately it seems I’m only using the small LR3 to make parts for the Full Sheet LR3. But I have a big project lined up as soon as I get this one back operational that I will have both of them running making Christmas decorations lol

Finally got my laptop acting right…

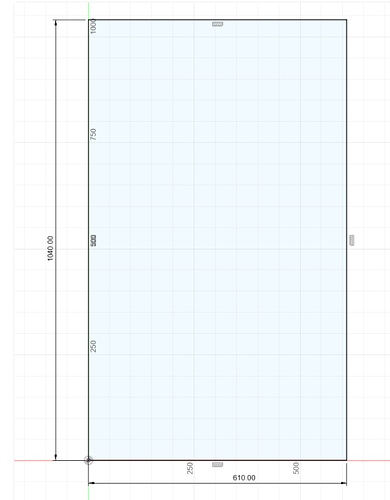

Not as good as further fabrication but it’s oriented how I wanted it and definitely a good start

Hrmm… Looks like you’ve got a nasty infection on your PC there… Best contact Redmond for a full factory reset… ![]()

(I jest, of course; you are free to pursue whatever masochistic computing fetishes you may have, plus, I have even been to the mothership in Cupertino and had coffee and pastries when my dad upgraded his iPad.)

I haven’t done a lot of marathon cutting sessions, but my K40 “cooler” is 3 gallons of distilled water and a couple of drops of aquarium algaecide in an old cat litter bucket with a tight-fitting lid. This is in an indoor basement workshop, so ambient air temp is probably averages low 70’s Farenheight.