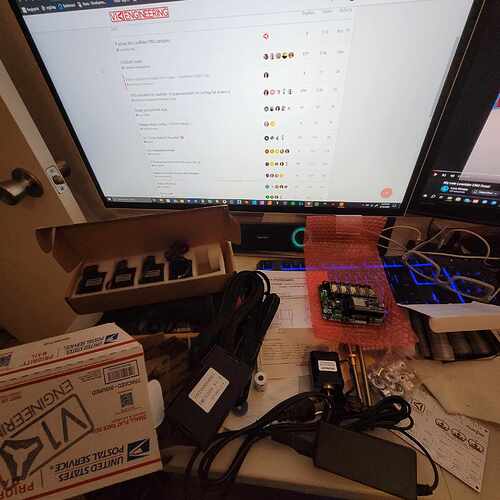

Hi guys, just got what I think is all my electronics in, along with some hardware.

For starters, MAN… these Nema17’s look little…lol.

I want to build a lowrider2 but with the lower wheels on it like the OG lowrider.

Ordered all the Hardware I think, hope I can run my jackpot controller with a VER2.

One thing that is throwing me off is the 200mm leadscrews are looking kind of short.

the ones in the YouTube videos look like 15-20" long. If yall can confirm that that would be great.

I have a very old Garageworks 24x36 router running MACH3 and Xylotex controller at the moment. I wanted to update and also be able to at least run up to 48" by 48" workable area. I hope I can accomplish that.

3D printers have made a lot of progress and the modern motors are very strong for their size. Nema23s are generally stronger, but these nema17s are definitely strong enough.

The calculator has been tested. If they are the right size, you will get the size you put in the calculator. Sometimes people use the screws they have, or they buy the next size up and never cut them.

I would advise to trust the process, but keep a list of things you think are strange. Revisit them (or let’s discuss them) after you have a feel for the machine. I don’t want to over sell it, but I think you’ll be impressed once it starts cutting.

Depends on what kind of lift you are looking for.

I went for 300mm screws with my LR2, which will lift the machine beyond any possible hope of actual cutting with any kind of accuracy, because I had them. Keep in mind that the LR2 (and 3 for that matter) get less rigid with height off of the table. But unused height doesn’t hurt it. So you can build for more height, but it’s potentially less useful.

I’ve seen some video of LR2s making foam surfboard cores, where some extreme heights were used, but I wouldnt expect good results.eith wood.

Anyway TR8 screws are inexpensive, so you can go with longer if the ones you have prove inadequate.

That’s quite ambitious. A 48" span is asking a lot, I would expect LR2 rails to sag in the middle.

There are some “double decker” builds out there that might have some remedies for that.

Could of swore I saw some LR2’s cutting full length sheet stock, none the less guess if that is to much to ask for then this might not be the build for me, back to searching for the right setup I guess… hope I can use the electronics for something else all Ill be out is the steppers. Thanks for your feedback.

I’m pretty sure you did see that, and are being warned of one of the symptoms of the LR2, that made the LR3 become the newest version.

Maybe the different way of saying it would have been, “You can absolutely do that, but with a 48” span, you will have better results with the LR3.

This is much larger than what should be recommended for a MPCNC style, without taking additional measures (and it will still at that span be better as a LR). And the LR2 can be done, but again might need some additional stiffness with a 48” cutting area. Where the braces and the struts, take care of that with a LR3.

But I’m sure you have your own ideas on why the LR2, is the direction you want to go. I feel people are just trying to set the correct expectations. The LR2 will do it, with modifications. But the LR3 will do it better, and not need any deviation from the plans.

But make no mistake about it, people build and tried full sheet builds of the MPCNC, and had success but with limitations.

Does that help?

It really does, thanks for the clarification. Much appreciated.

It can, but be aware that you are very lokely to have some sag. I believe the LR3 would be better, but that’s also a known upgrade path if the LR2 doesn’t meet expectations.

The LR2 is easier to make taller, so it gets an edge there.

I used my LR2 to cut full sheet. I was using stainless steel tubes. However, the same two tubes are now on my LR3, and the LR3 is better for stiffness across the wide gantry. If I were in your shoes now, I would skip the LR2 and go straight for the LR3.

I think he’s talking about a 96" span not 48" span and 96" length.

Anyway, it depends on the target Z travel. Though I think Jamie had a parametric YZ plate for any length Z rails, one thing the LR3 lacks is an ability to relatively easily add under-table wheels to constrain it there (though your hidden belt mods might be expandable to 2D captured SuperStrut rails, now that I think about it…) With the extant Y rail, that is actually pretty much a fully captured machine at that point.

That would be a major point of weakness.

I may have missed what implies that. I assumed based on this…

… That he was talking about a 48 inch X cutting area and an expanded Y cutting area to be able to do full sheet.

I feel like I too am confused, and feel Juan will need to clarify if we haven’t provided the clarity he was seeking.

I was under the impression Juan was seeking a machine, that had a 48 inch x 48 inch working area.

When told it would potentially sag in the middle, on a LR2 at 48 inches, I feel he made a comment about being confused as he believed he had seen full sheet LR2’s. I don’t think at this point he is concerned with a 96” dimension yet. I feel he was requesting more information on why a LR2 would have potential challenges at doing 48x48, if he was finding 48x48+ LR2’s documented on the forum.

The only variable I’m aware that might still need clarification is his desired Z travel. So far the only question about Z, is if he got the correct lead screws from Ryan. It was my understanding he thought they would be longer, based on YT viewing, and was making sure he got the correct screws. (In his defense, my first LR build, I was also “surprised” upon opening the box, and thought “how tiny”. But using Ryan’s shop for a few years prior, continued my build to find out my “new tiny lead screws” were the correct size for a LR3 build.

With all that said, it more than likely that I am the one confused.

Sorry for the misunderstanding I just want to be able to have a cut area of 48" by 48" basically able to cut half of a sheet.

No, You are absolutely right, that is exactly what I was trying to relate.

Sorry for the misunderstanding you are right I just want to be able to cut a 48" by 48" cutting area. Half a sheet.

48" is totally fine. The LR2 can do that.