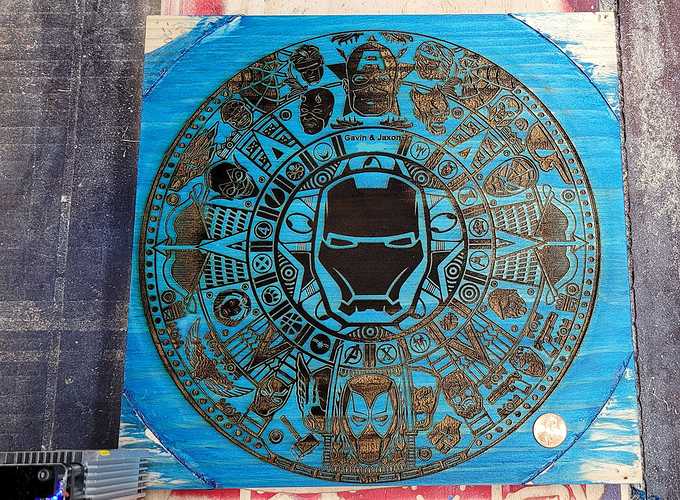

It took less than an hour to fashion a mount with extra parts and wire up a new laser I got for Christmas to my Lowrider2 run with an SKR Pro board. The laser is of the three-wire (12+ / 12- / 5v signal) variety. I was going to try to CNC this project, but decided to use the laser instead. I was not disappointed, and neither were my nephews. Lightburn was surprisingly easy to figure out right out of the box.

That came out great.

Thanks Ryan. I expected a lot more head scratching when getting the laser to work, but it ended up being super easy. The forums helped a lot.

One day the instructions should work ![]()

The lasers just move so fast it is hard to keep up, when I finally did a full laser workup marlin firmware revamped the whole laser codebase, within a month so now I have to do it all again.

then you have the variety of all the boards that throw a wrench into things… That’s going to be quite a writeup.

I love the “Made by Uncle Corey With Lasers and FIRE!” Nice touch!

Just one misstake… you are suposed to use a banana for scale!

Looks more like a Marvel Comics calendar to me.

That may be correct, I honestly have no idea.

In the middle, that’s Iron Man, on top Captain America, to his left that’s Cyclops from the X-men and Daredevil, than there’s Spiderman, Thor’s hammer Mjölnir, the Avengers logo… everything from the Marvel universe.

DC Comics characters are Batman, Wonder Woman, Superman, Green Lantern, etc.

Anyway, turned out great!

I really like the way this piece turned out. I am sure your nephews love it. First of all, they have a “one of a kind piece”, unless of course someone else in their circle of friends has a laser cutter and this pattern and painted the same color background. Likely? No. This makes me want to add a laser to my MPCNC. I fear it is just jealousy on my part.