So a friend’s neighbor wanted to know if I could replicate a birdhouse. The one he has was made by somebody and has an octagonal shape, with an octagonal peaked roof. The pieces of which are fit together tightly.

It is old, and is falling apart. The owner is an elderly Norwegian gentleman, who is … difficult to understand, and seems.to have difficulty understanding what I’m asking. Anyway, it seems that something just like the original is what he wants.

Of course the mitered edges are easy enough on the table saw, though the 8 roof pieces are a bit harder to get the exact angles. I suspect that the original might have been made with arbitrary triangles of less than 22.5° and then joined using the kerf of a saw. If I’m going to use the CNC though, I want something repeatable. More like I want to be able to produce more than one of rhe things.

Mostly though I’m considering this as a project where maybe I can learn some new things.

So one possibility of course is maybe to 3D print the roof sections. Coat it with something UV resistant and call it done. It’s a bit big to 3D print entirely, but pretty sure the 300mm bed would let me print it in pieces, but of course that doesn’t get the wood stain finish that the current one has… it would let me have a nice “shingle” texture, so maybe acceptable? Hard to say…

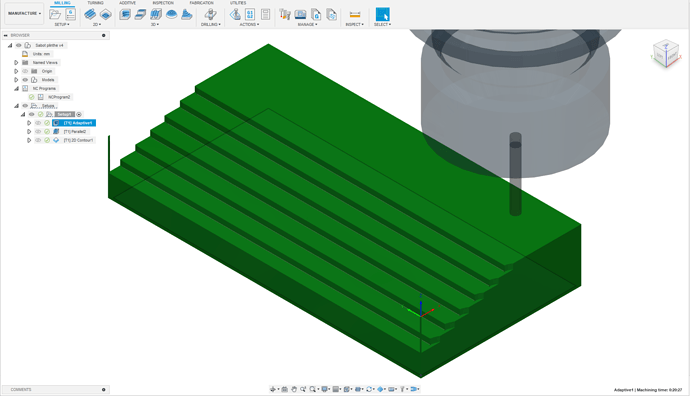

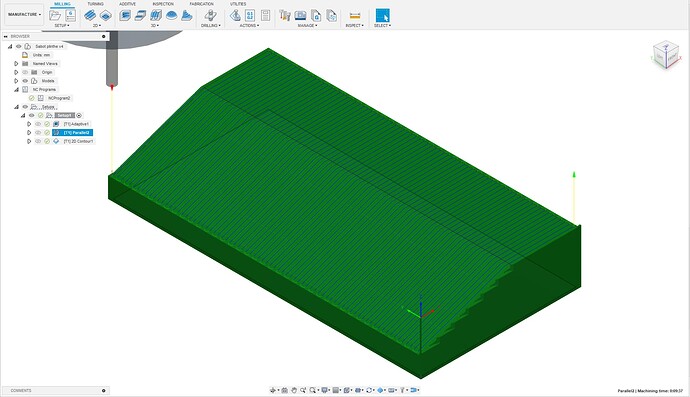

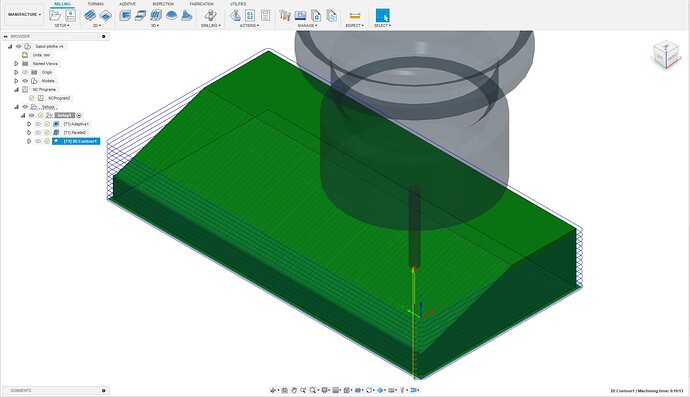

Anyway, similar problems have come up with other ideas that I have had, and I would like to know if there is a way to get mitered edges in the CAM. A 3D cut shouldn’t be required, so I would hope I don’t need to base the cut off of an .STL file, which would spend a lot of time cutting air… so far that is all that I know how to use Estlcam to do this, and I haven’t actually ever done it.

I do also have Fusion360, though I have never actually used it for CAM. The parts will most likely be drawn in Fusion360. Might be time to learn to use a postprocessor for it.

Any ideas on how to get this effect? I have ball nose end mills available. I don’t mind some “stair steps” on the final finish, either.