I didn’t wire my ENA pins on purpose so my motors are on all the time and Z doesn’t accidentally drop, for instance. ![]()

I intentionally used 1mm pitch lead screw for Z so that it never drops ![]()

(Talk about LR2 PTSD)

Since there are so few boards, let’s give one away. Since they are new, you are basically a beta tester. So post a picture of your MPCNC or LowRider to this Twitter post, https://twitter.com/V1Engineering/status/1683264473845620736?s=20 , and I will select a random winner Tuesday at noon.

If you won’t be able to use it for a while, maybe just hold off until they are for sale, I need them to be used to get some feedback.

If Twitter is not your thing, I am sorry, it is the easiest way to do this for me. It is a lot easier than submitting a recent YouTube video featuring one of the machines…maybe that is next, though.

That’s the first time I have logged into twitter in a LONG time LOL. Photo posted… New machine should be mounted tomorrow and getting wired. Although I’m am perfectly happy paying for it…

International giveaway? (México)

Perfect timing, I’m finishing my LR3, and my old Anet A8 would benefit more with the SKR pro board.

I have read every post in this thread, and even if my machine was finished I don’t think I’d be able to use it for a while! ![]()

![]()

It’s exciting stuff watching you blokes talk in your own weird language, but I’m going to have to wait for the plain English version to come out I’m afraid!

I’m waiting for the release version… Not that I need one, as I still have 2 Duet 2 Wifi boards unused, and I like the RRF interface, plus everything set up on both the Primo and LR3…

I do, however have almost everything for another Primo printed, and almost enough spare LR3 parts to make another, which I’d really like to use for a plasma cutter build…

Might need to wait until I can get 220V to the garage though.

Great suggestion Barry!

CLASSY!

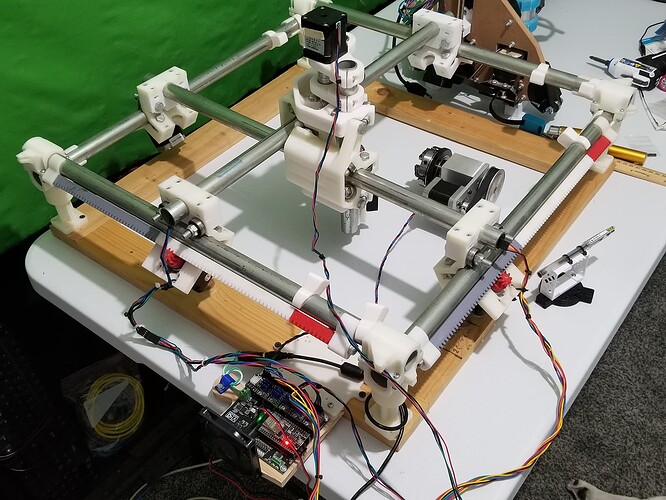

Here’s the MPCNC at the moment:

The 4th axis moves but it is “C” whereas I might prefer to call it “A”. I’m sure I can do that in the config.

I’m still working on getting endstops hooked up so I can home/square.

I’m temporarily using the 5V from the expansion port to power a fan. Totally unnecessary but I wanted it. When a 12V fan is driven at 5V it is very quiet.

Going to print a bracket to mount Doug’s magnetic kinematic base in the laser clamp. Then time for a crown.

Any suggestions for a pen on the rotary axis? Not the season for easter eggs but I might try that.

Partly printed, mostly clear acrylic case showing off the jackpot board would go well with those acrylic YZ plates and sweet Aluminum grill… Happy to share a complimenting case design if that helps…

Personally appreciate Jonathan’s persistence and ability to improvise, adapt and overcome build challenges.

Hell yeah! I’m not a designer at all so that would be AWESOME!!! Only thing to remember is i use 2.5" flex hose for my dust collection…if that makes any difference in your design at all…

Edit to add…I have some 1/4" Aluminum left if you want to incorporate that in the design as well. Then it will tie in with the build completely LOL

I found this is especially useful for laser machines. Having buttons to turn the laser on (lower power) and off for setup and prep purposes has been super convenient.

I previously had a macro called “laser pointer” that would take the laser on at a very small power so that I could precisely set the homing point

Great use case for a dedicated button indeed

On grbl though, the laser only activates when moving, so it kinda defeats the purpose

Make your macro wiggle 0.1mm each way.

Or a small circle! Even better calibration.

I think there’s an option somewhere to activate the laser even when not moving

Either way I need to investigate this, because the laser does not power off instantly after the end of movement, it stays on for something like 10-15s, which is a bit dangerous >_<

I need to read the grbl documentation on laser mode

Fluidnc is compatible with grbl, but have more options and capabilities. Perhaps fluidnc has something as well.

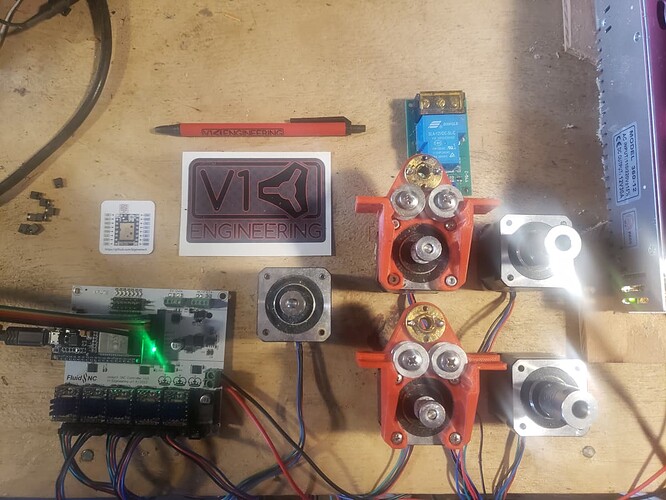

Here’s a rev1 jackpot board connected to my testbench.Am doing some testing with fluidnc before starting migration to klipper.

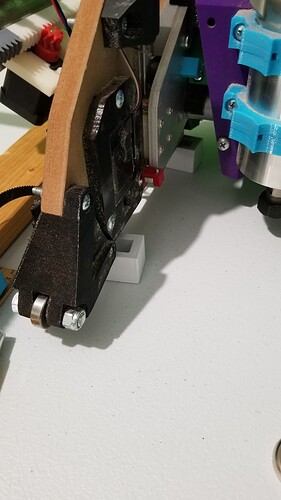

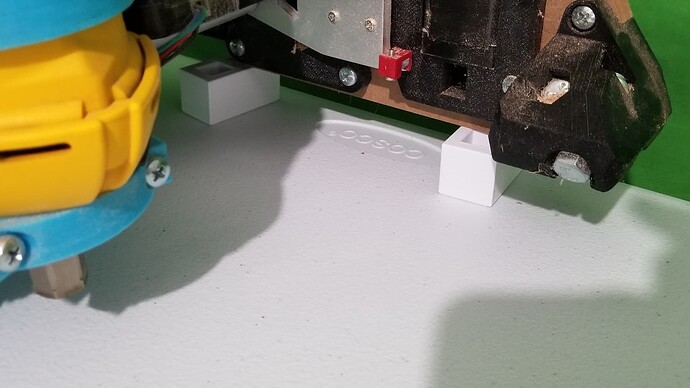

This must be for a custom design and not a V1 machine. I don’t remember anything that had idlers and threaded screws on the same mount.

It’s from the lowrider 2. I have the lowrider 3 parts printed for my 2nd machine but have not as yet moved the parts.

Ahh ok. Been too long since I had/worked on a LR2 lol