Cool, I think I can use the rev1 version for testing. Let me know how to purchase.

PM’d you.

So far so good I think. I will monitor it today since there should be a ton of testing and report back. So far the laptop itself is running as it should be, warm and occasionally the fans kick on for a minute, the usual.

I came across this yesterday, Axes | Wiki.js. That seems to specify a max speed. Does that make more sense to anyone?

Current config is -

stepping:

engine: I2S_STATIC

idle_ms: 255

pulse_us: 4

dir_delay_us: 1

disable_delay_us: 0

steps_per_mm: 50.000 (with 8th microstepping)

Are my decimals in the right place, with a theoretical max of 833,333 steps per second (83kHz?)? so 16k mm/s so I should have no fear turning that back up to 16th microstepping (8k mm/s) if needed.

This should also shed some light on a theoretical max for raster etching, I think.

I am calculating 125 k steps per second (4 us high and 4 us low = 8 microsecond period and 125kHz).

Then at 50 steps per mm @ 8th microsteps (200 full steps = 32 mm, 1600 8th steps = 32 mm, 50 8th steps = 1mm)

125 k steps/second is 2.5k mm/sec. Or 150,000 mm/min in Marlin units. 75,000 mm/min is plenty I would think, so 16th microstepping should be fine.

Actually 9 microsecond period: 2*pulse_us + dir_delay_us, so 111 kHz.

It is I2S, there is no I2C involved. The I2S lines connect directly to the serial-in, paralllel-out shift registers.

Okay, now we know ceiling is 1250mm/s, ![]()

Okay it is all working simple mistake on my part, just took a lot to get there.

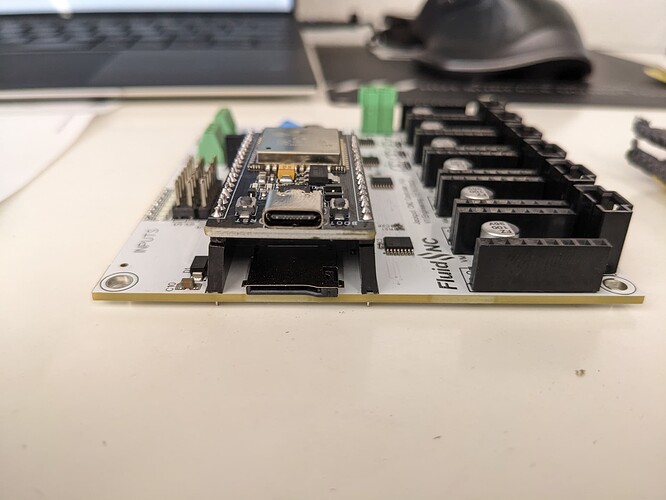

Preliminary tests show 35mm/s raster same parameters as before with the AP mode turned off…AP mode is the most memory intensive and getting worked on right now. So Faster than Marlin, not as fast as GRBL-HAL…but that is just first initial tests. I am going to order a few more test boards from another board house to see if there are any differences in build quality.

So I should get to play around a bit more this evening and might sell a couple boards if there are two of you that have time to play/test them asap. Then after that a steady flow of boards if they check out.

Are there specific issues that you’ve noted there? If so, feel free to drop me an e-mail with images and I can give you a 2nd opinion there.

I know you are working on the laser side of it now… but if you want one tested out on an LR3 I’m back in town and will be finishing up the new LR3 in the next few days

No, the only issue is the bottom seemed a bit dirty, like the flux didn’t get washed off well. The white had a bit of burn/brown. So I think I will see how PCBWAY look. I met with them at open sauce and they said they might give me a good deal on some samples, worth a shot

Okay, let me see how this evening goes.

CRAP, I ordered 100 of the USBC esp32…they are one row more narrow. GRRRRRR

That’s a very weird change. Easy enough to make it a ‘dual’ footprint, if you wanted, though. Or you could just bite the bullet and I can help you land the ESP32 module directly on the board ![]()

Right, I remember you mentioning that before. Do you have a photo? It would be rare to get a board back that was completely cleaned unless you specify it. Could always try bringing it up with them and specifying you want it to be cleaned end-of-line.

I suspect the browning/burning is a hand assembly thing, so that will go away with decent ordering volume. What that volume is is tough to tell. 100 pieces here in NZ was definitely going down the wave solder line. 100 pieces when I was working for Qualcomm was going through the selective solder station. 100 pieces in China is likely still thoroughly in hand-assembly territory unless you specify.

The latest boards I’ve done are all 100% SMT unfortunately so I don’t even have a good example, but let me know if you’d like it quoted via my contact at Shenzen 2 U.

Most of Barts Boards are dual footprints. I just need to pay more attention on my orders. Dang it.

Might as well, just a small order 5-10 if possible. Just check them all out to see how it goes.

Again, this is just the price you pay working with hobby level components, sadly. Poor or misleading documentation, much less uniformity across product lines, etc. It’s the cost of things being as cheap as they are. If I were in your position, I’d be absolutely stoked that I only had a few of those boards, it’s an almost zero-danger change to make to the board and they fit with some bending that isn’t going to hurt anything. That’s a victory from the jaws of defeat, for sure.

I’ve never ordered anything that small through them, but I can ask. Was more thinking that it would be a good idea to give you a ballpark on production costs as I don’t know specifically if the PCBWay online quote options are particularly good. My suspicion is that there’s a lot more margin built into them than appears, not that it may matter all that much.

Actually, I think I may be able to generate the gerbers from EasyEDA myself. I’ll take a look later on.

Sounds good! I’m home for 26ish days so ill have plenty of time to test and report back

That is weird in one of the newtech youtubes i watched he showed the same problem!! It was on a screw terminal type board.