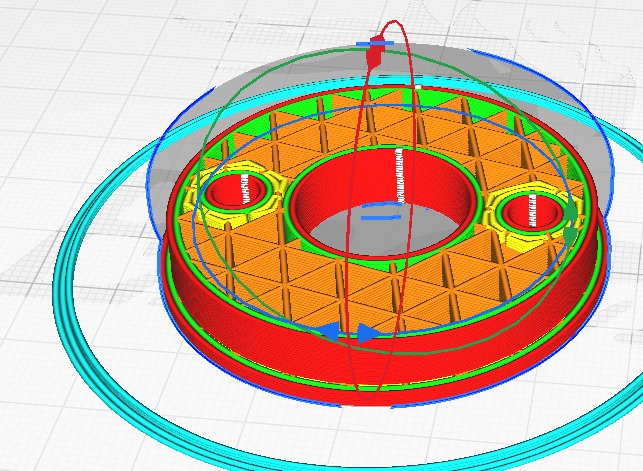

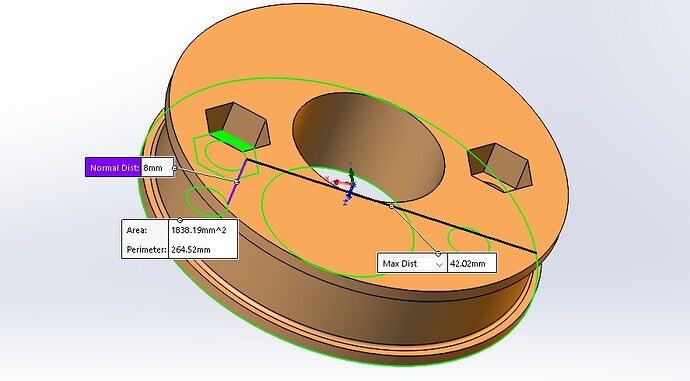

Hi I have a “trusty” old ender 3 lightly modified. I’m not a printing expert. I’m having problems. Every time I try to print this wheel, it’s a good Z0-Z8.3mm, after which the layer has moved out of place. And it’s at the same height every time. I can’t find a mechanical fault. I’ve tested the belts. Also everything else moves freely and normally. I recently changed to a 0.8mm nozzle, could that be the problem? I’ve printed other stuff between these wheels, and they were fine. So could the problem be related to the bottom of the nut hole or the next layer (layer thickness 0.36mm)? The bottom of the nut hole should be 8.0mm above the build plate. Could cura do something to the nozzle that would cause the movement. The layer is always in the same direction out of place. One roller is lower than the others, and even there the movement occurs at the height of the bottom of the nut.

If you print a different part, that is at least as tall, does that have problems in the same Z height?

What if you print that part in different locations on your bed? Always a problem at the same Z height?

I just dealt with a similar frustrating layer shift at about 6mm from the bed. For me it ended up being a belt tension problem (one belt was tighter than the other.) I’ve never used an Ender 3. Just pointing out that it did turn out to be a mechanical problem for me.

I had also done the things MakerJim is suggesting. Move things around, and rotate them 90 degrees to test whether it keeps happening. I also noticed that something had changed in one of my profiles that resulted in 0 z-hop/z-lift. (I can’t imagine who changed it since I’m the only one that uses it. ![]() .)

.)

The z-hop issue did occasionally contribute to the problem, so I fixed it at the same time.

I will try to print more stuff tomorrow, in different orientation and place in bed. I did make some changes into slicing srttings. It is confusing because the problem is only in this part (so far) I printed several higher parts between first and last wheel and they were fine.

The nut hole is 5mm deep from top surface. One wheel were 10mm high so there the movements was from 5.3mm heigh. I did raise the wheel hight from 10 to 13 from another reasons so other wheels were 13mm high and these wheels had movements from 8.3-8.36mm heigh.

This is a really good point. It looks like you’re using 0.36 layer height on a 0.8 nozzle? If the extrusion settings aren’t well tuned it would be easy to create little artifacts that may collide with the nozzle. Hopefully rotating or shifting the parts would help clarify. In the pictures there may be some over extrusion on the right two wheels’ top layers.

Also, are you printing these individually, or are you printing a plate of the wheels? Also, what speed are you printing at? Does slowing down change the height or affect it?

Thaks you all.

I did tighten POM wheels from printer a little, just in case and I have added little more tension for belts. I cleaned the printer and lubricated the t8 rod.

I did print few calibration cubes with lower flow. and there was no shifting. there were just little streaks at cubes sides.

Before calibration cubes, I find that I have used wrong coasting volume for 0.8mm nozzle. So, I fixed that for the cubes.

I did swap 0.4mm nozzle back and made the calibration cube and I printed one wheel successfully with the .4 nozzle.

So, I think my cura settings for 0.8mm are bad

My print speed is usually 50 mm/s and I drive 90% speed for .8 nozzle. I do use 0.36mm layer height for 0.8mm nozzle that is good balance for quality and speed, I think.

I had an issue that was similar and troubleshot for a while. I had already put the KevinAKASam dual belt mod on and I would get a repeating band on a test cylinder. I am convinced it was a pom wheel with a slight nick in it. I changed to linear rails for Z and it is perfect all the time now.