I was making a cut and noticed that the core would “wiggle” every so often. I don’t remember ever seeing this before. After the cut was finished I tried to move the core by hand and everything feels rock solid. What do y’all think this could be??

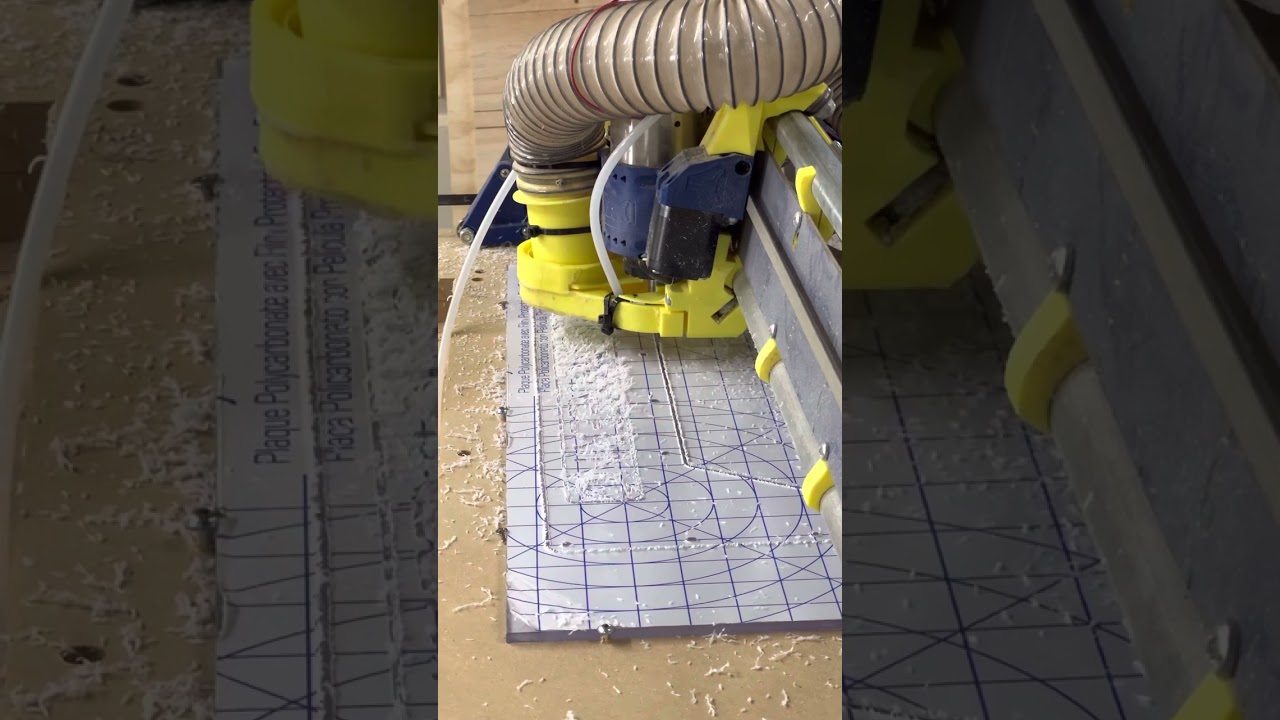

During the last few seconds of the video you can see that your Y might be the problem, running over some chips and moving up and down doing that. That’s because you didn’t heed my warning about cutting plastic without a good vacuum. ![]()

![]()

I had the Dust Collection going but between the air blower and the spindle fan blowing the opposite direction it didn’t do much. But if you watch the part where it comes up and around what would be the right side then back across it does it a lot in there and Y isn’t moving at all. Starting around the 40 second mark in the video. Y isn’t moving at all though that section.

After closer inspection and after walking away from it for a few min I found one of the bottom bearings not touching. I tightened up the opposite bearing less than 1/8 of a turn and all is well again. When I found that one loose I went trying to move the core and found in one cross direction I could get some wiggle. After tightening the bearing it’s rock solid again.

which bearing is that? because I’m having the same issue

I will try to get some pics and better explain here in just a few.

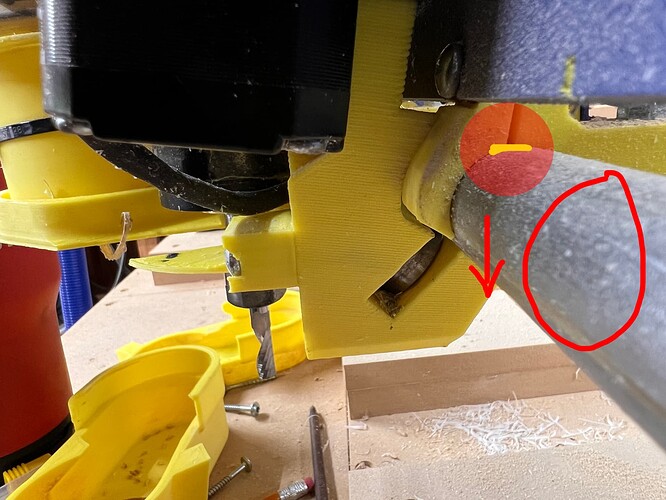

Ok here are a few pics. Don’t mind my crappy paint skills but the red circle shows the bearing that was loose and the blue is the bolt/bearing I had to tighten. Now it didn’t take much at all!!! Very very little adjustment and then check. Honestly if you can position yourself to have one hand on the loose bearing as you tighten the other one that is best. You will be surprised how little it takes.

Many think Greg was the core Wiggle, but I always thought it was Anthony. Jeff was always comic relief, and Murray was just the gangly guitar player…

Well… I thought I had it fixed. Turns out it came back today. No problem I adjusted it a touch more. Now I have a new problem. To get it tight enough to not “wiggle” the core hits the braces. But only on one side. I have adjusted every way I can think of and cant get it to stop hitting and also not be lose on the beam. After 20 min of adjusting I got it to BARELY miss on the X+ side but its hitting somewhere in the middle of the core on the bottom. What am I missing? This was never an issue before only as of recent. Nothing has changed other than the weather. Video was before I made any adjustments. Still doing the same thing just catching in the middle not the X+ edge

It looks exactly like my problem when my printer wasn’t square and the core not really fitting. I also didn’t notice it for quite a while.

Can you print a big test square (like this: Der Froschkönig - Lowrider 3 in Oldenburg, Germany - #182 by Tokoloshe)?

I went looking for your thread but got side tracked before I could find it. Hoped you would find your way here. I will print the test square once what is printing is done. That will be the same printer I printed the core on…I believe. Not 100% sure. I’ve slept since then lol. Hoping to have the V4 back together tonight with all its side panels on and run some test prints for square on it. Need to get the core for the 2nd LR3 printed and now possibly a new core for this one as well. I’ve gone though and loosened all the braces to make sure I wasn’t pulling them too tight. I don’t think I was. Now i have it adjusted to where it barely touches but has extreme minimal deflection in the core. That will have to do for now. Have a cut I need to make that I don’t want to wait for a new core to be printed for lol. Luckily its not dimension critical.

I basically live here, the chances were good. ![]()

hey bud did you fix it? im getting the same issue i end up tightening it to much and cracking the core but it works lol i need to reprint another core but i notice it when i pull up the pipe some and put like a bamboo shim in it , it fixed the ‘‘wiggle’’ in some places in

I haven’t fixed it yet. I work off shore and won’t be back home till later in July. I’m currently building another smaller LR3 and once it’s up and running I plan to take this one down and reprint the core and the braces. Will probably go ahead and upgrade it to 1/4” aluminum struts as well

You could check my link above, there are a lot of posts until I found the solution, but it might help to check.