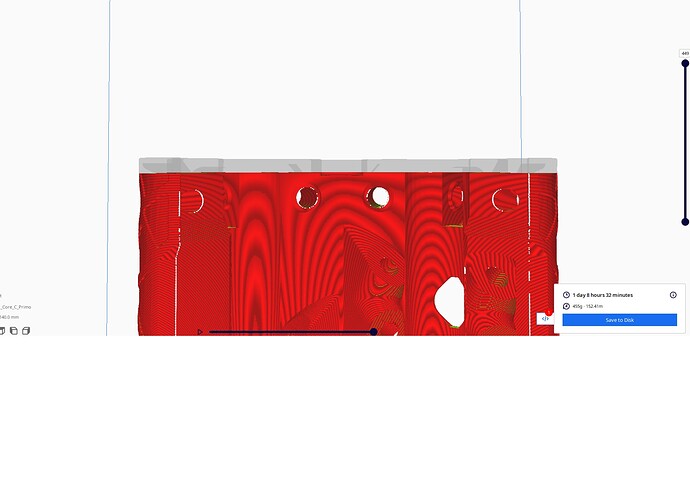

Hello. The core got to heavy for my printer and slipped at the last 5.6 mm. how important is this last little bit. Will it effect anything?

I took a look at mine and I don’t think it will stop the machine functioning but not having that end ‘capped’ by a few layers will likely affect rigidity of the piece. Whether it’s in a way that’s enough to be meaningful, I don’t know.

I’d probably go ahead and assemble it anyway as it’ll let you trouble shoot other stuff and verify that everything goes together well.

Assuming everything’s fine, you could just use it as is, you could re-print just the top 5mm and epoxy it on or just take another stab at it.

Were you using a brim or anything? Last time I printed an LR3 core I used a huge 10mm brim and I think that might have saved my print because a corner lifted by maybe 1mm and peeled up half the width of the brim.

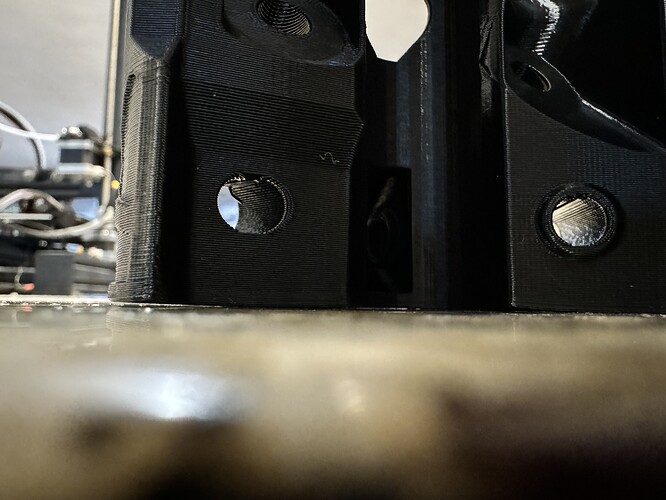

Thank you. The 75% infill makes it look capped already lol. No no brim. My print bed is normally really good and I’ve never had problems. Came home from work today and noticed the two corners were up a little with 4 hours to go…… Could see light underneath the edges of the print…. Crossed my fingers that it would hold. 2 hours later it shifted. I didnt realize how heavy the part was until I picked it up. Might slather some epoxy in the top later if once I assemble it and everything looks fine. Thanks again.

Definitely give it an assemble, then. Depending on how much it warped before pinging off and where that warping is, you might see issues with it not sitting on the rails right. If that’s the case then you’ve got something to try fix for the inevitable next print.

What material did you print that in? There’s some notable warping at the base.

PLA 200° 70° 75%.

70C bed temp? That’s very high for PLA and may be why you’re getting warping.

I’ve never had issues before. I think the 75% infill caused some shrinking that my normal settings just weren’t capable of handling. Probably should have used some bed adhesion in the slice.

Maybe I’ll cool it down next time to 60 if I need to reprint this.

Looks decent to me, I’d definitely give that a shot and see how it went. It’s some decent warping but looks like it clears quickly.

@thccustoms , welcome! Where did the 75% come from? If you decide to reprint you should try to use variable infill.

The core can be printed with variable infill to save time and plastic. 70%/30%/70% split at 24mm and 116mm.

That worked well for me.

I was going to say straight from the directions but I went back and checked and yeah…… lol. If this doesn’t work I’ll try the split infill thing. TY

I think what “saved” my core was a fail on a previous rather big piece of the CNC.

That led me to using a brim, 7mm if I remember correctly. Variable infill and 60 deg bed too.

I was not expecting it to work well on the first try but it did!