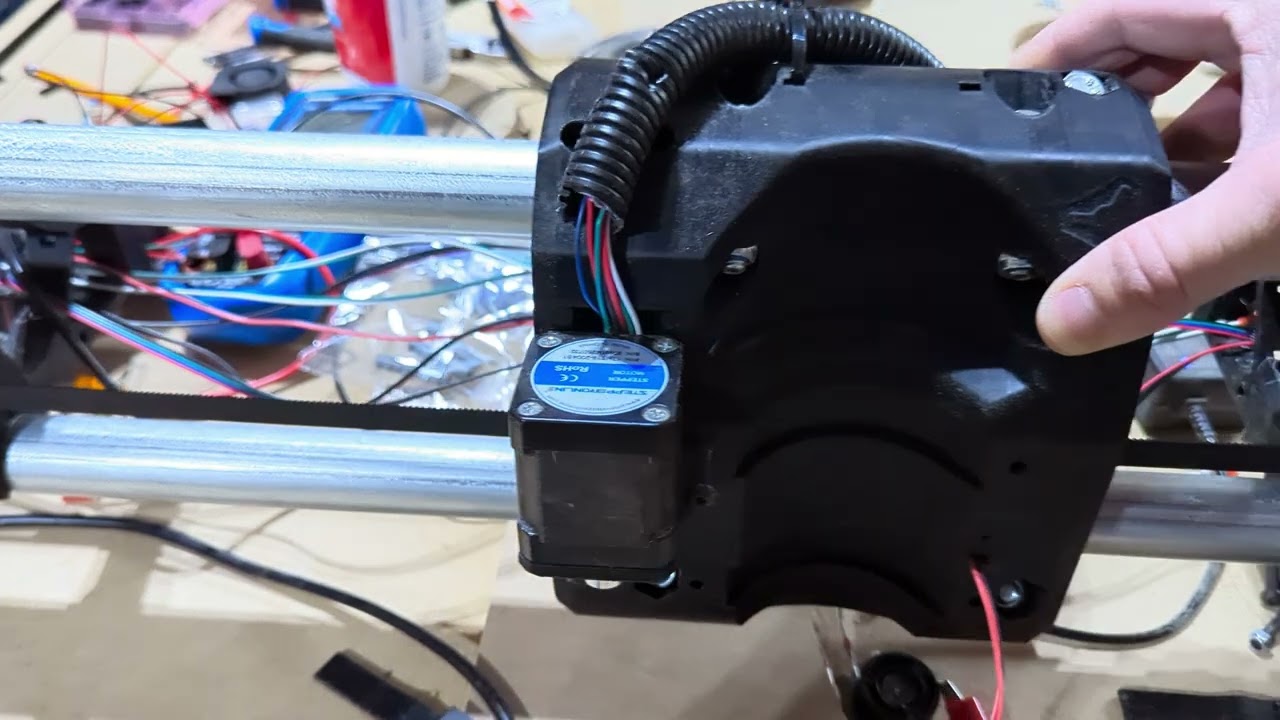

I have most of my LR4 built but have noticed that the Core will make a grinding noise going back and forth on the x axis. I checked the pulley and idlers and it doesnt appear to be an issue with them. I have uploaded a video for more context. I am hoping this is an easy fix? Thanks everyone in advance!

It’s hard to tell in videos because lots of sounds get picked up….

But, it sounds to me like most of the noise of the motor being turned.

You don’t really want to move your core back and forth like that by hand if your electronics are hooked up.

If it’s a different noise than the motor noise, then I would suggest disconnecting the belt and moving it again so we can hear whatever noise it is without the motor noise interfering.

It is normal for the motor to have resistance and make some noise when you are moving it under your own power

The electronics are hooked up but not powered up. It’s jittery on the gantry moving it back and forth like it’s skipping steroids but the belt and pulleys are turning so I’m just not sure what’s going on. I tried loosening and then tightening the top bearing nuts on the core and unfortunately it didn’t really help.

Doing this is turning your motor into a little generator and will feed power back to your board and can cause problems.

Checking for smooth operation should be done before the belt is connected at each end.

Is it worse there in the middle?

Seems like it got better to the right side?

Is your pipe smooth? Have you tried spinning the pipes so the bearings are on a fresh section?

Blew up an old ramps board like that! Steppers make awesome generators!

I’d disconnect the motor from the control board and try moving it again. If it is still hard there may be a short in the motor wiring. If it is much easier, then resistance internal to the control board is what’s making it harder to turn when it is connected, and I wouldn’t worry about it.

One way to find the pairs in a stepper motor is to connect 2 of the 4 wires together and if that makes the motor harder to turn by hand, that pair makes up one of the motor windings. If the pins to the board are shorting a pair together, you’re doing the same thing.

I rotated the conduit and also moved it with less force and it seems to work great. I think the problem is solved.

Thank you for your help guys!

Didn’t Mike solve it? ![]()

lol, sorry about that. i clicked the wrong post. will rectify it.

No worries, I think it happens quite a bit because people tend to summarize what the mistake was and then mark it as the solution, because it obviously is, but with that taking away the „achievement“ of the one who actually gave the tip. Happens quite often and is completely understandable. ![]()