Today I noticed that one of the bearings on my core is not moving when I slide the core across the pipes. It is the bottom right back bearing that does not have contact with the pipe. This causes a slight wobble, although very tiny and barely noticeable. Any suggestions how I can adjust this? I already tried tightening the bolts but without succes. I’m afraid to further tightening it and breaking it.

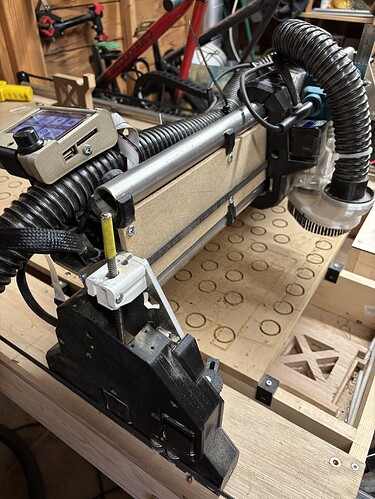

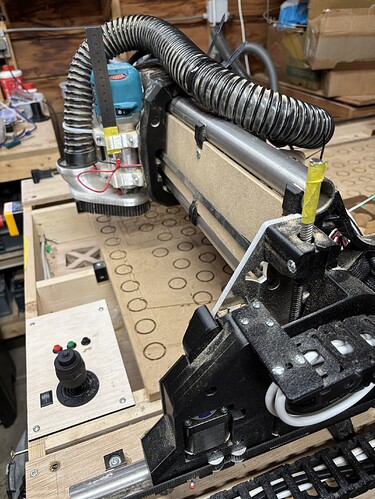

Which LR do you have? Did you tighten the correct bolts? Pictures help. ![]()

Start the other way. Loosen the tension bolts all the way. Move it around to reset it, then only tighten the one not making contact by a 1/16 of a turn at a time.

Also make sure you have not tightened things so much you crushed the part and have clamped the bearing.

Ok will try that! The bearing that is not moving was not tight at all, so that should not be crushed.

It’s a LR4, I will make a picture if Ryans suggestions won’t help.

The LR4 can only really be tightened at the top with two of the screws/nuts. There is a slit in the core, you can’t miss it. That’s where it tightens.

Funny you say it can’t be missed! My brain gets a little foggy sometimes from a health issue. I kept tightening the bolts and couldn’t get the slop out, well you have got to tension the other bolts on top of the core! Ended up cracking the core. So I had to print another one.![]() Pretty easy to swap out so that was nice.

Pretty easy to swap out so that was nice.

I loosened up the two tension bolds and moved the core side ways couple of times. The left bearings all keep contact with the pipes, only the bottom right back one does not make contact. After tightening bit by bit it does now when it is on the left side of the gantry, but right just before it passes the middle when I move it to the right it’s not making contact anymore.

I’m afraid to tighten it more as it already needs quite some force. Did not hear a crack jet, so I don’t think it is broken.

I also turned the 2 pipes a bit to see if they are perhaps a bit bend, but the issue remains. When the core is on the left, so all bearings touch the pipes it feels a bit more solid then when it is on the right, although the difference is small. Also when I press a little bit just below te bearing when it is moving it does make contact.

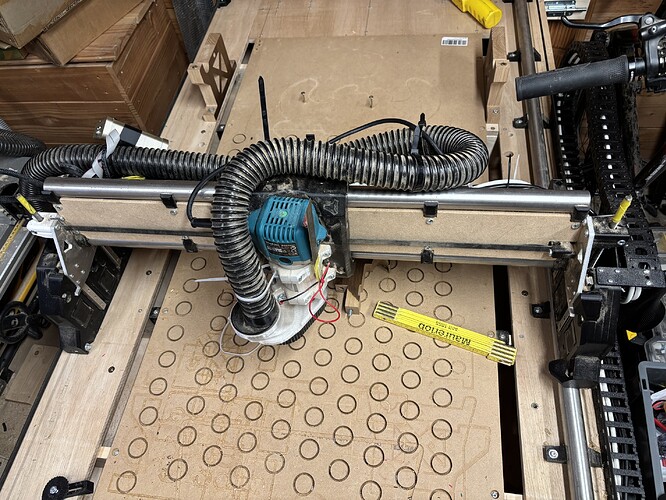

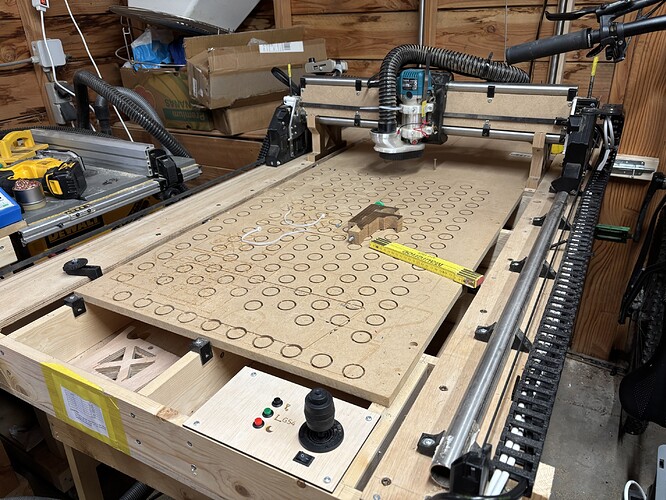

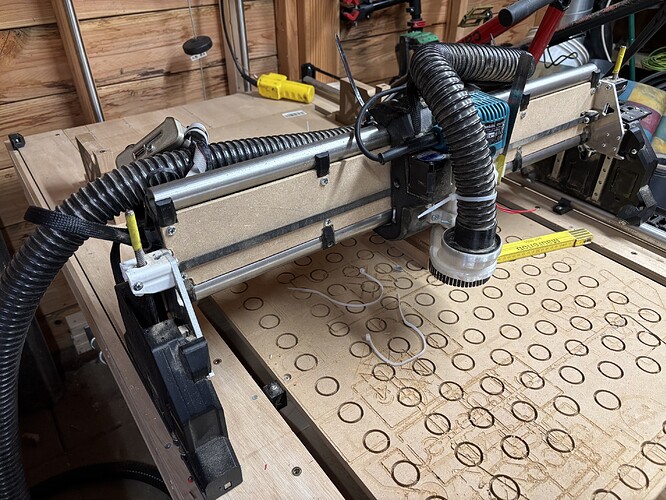

Let’s see a whole picture of your build.

See if all your braces are tensioned about the same.

If you have calipers you can measure the distance apart of the X rails. Looser makes them closer, tighter makes them further.

Checked today, and indeed this was it. I tightened the right side, and now it is connecting al the way! Thanks for your help!