So the first two attempts were close, but not quite at the cigar stage. The first attempt was way too small at the threaded hose fitting, and a little too large where it fit into the dust shoe (taper was a little too small). This latter issue ended up breaking the dust shoe at the screw hole:

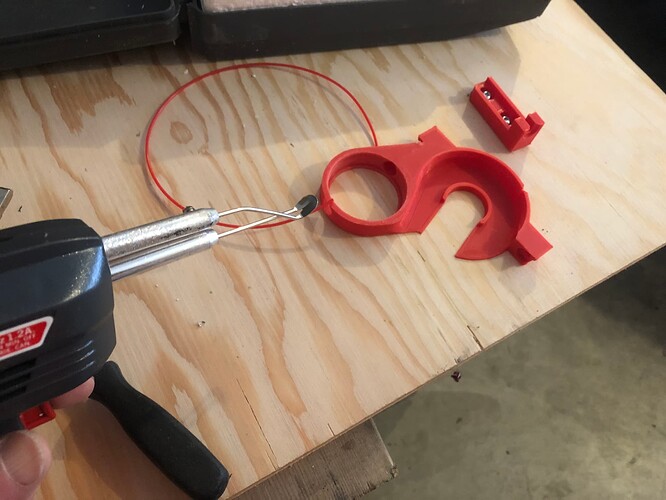

This led to me not only having to adjust the design, but to also repair the crack (using the handy solder pistol that has been sitting on my garage shelf for a few decades)…

It worked reasonably well, and seems stronger than the original at that point (but not necessarily as pretty).

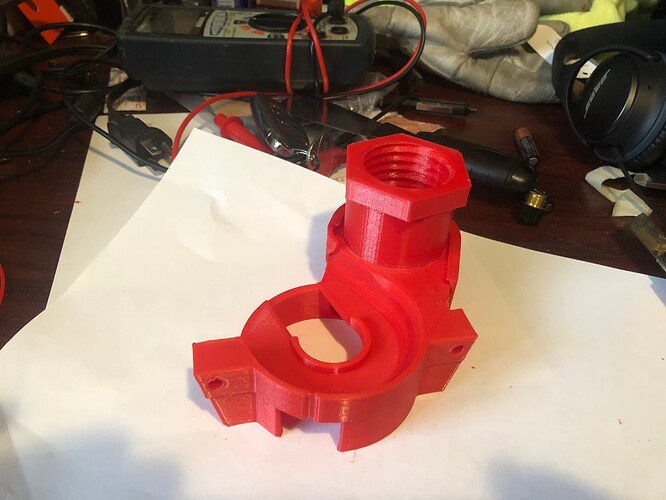

I then went back to Fusion 360 and adjusted the barrel taper, and re-sized the threads to 42 x 5 mm. This version was a little too small at the barrel (taper too large), and the threads were close, but started binding after 1-2 turns.

The third attempt was pretty much spot on. I split the difference on the taper (ended up with 0.95 degrees), and added some offset to the thread faces, allowing for a bit more clearance. This version was very close, with the barrel fitting snugly into the dust shoe without any force required (after a tiny amount of post-processing with some 120 grit garnet paper), and the threads turned smoothly for the first inch or so before becoming a bit stiff. So I decided to award myself the cigar!

Maybe not the most exciting first CAD attempt, but I did it by myself, and it mostly does what I wanted it to, so I count that as a win!

Thanks to all for the encouragement and suggestions.