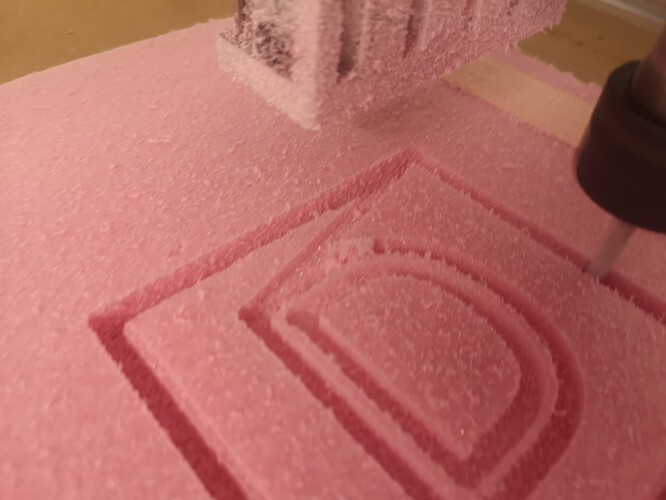

I have a couple of problems that I can’t solve. It happens that the Z axis goes down and changes the zero position every now and then. So, I set the zero positions, cutting/carving starts and then the first cut is 2mm deep, and on the Estlcam it shows 1mm, then in the next round it goes to a depth of 5mm, and on the controller it shows -2. After that, it continues in that depth and so it goes deeper and deeper. When it moves from one position to another, the spindle does not rise above the surface, but cuts across it…

at one point the depth is about -25mm, and on the controller it shows -2mm. I calibrated the machine according to the instructions and everything is fine. 1mm is really 1mm on each axis.

Besides, when he’s done, he returns it to the starting position and it says 5mm on the controller, but it’s actually at zero, or notched to -2 or something like that. I created this file in Estlcam, because I thought I made a mistake when preparing it in Aspire.

The next problem, which is very important to me, concerns the limiter.

I have built-in inductive switches, but I can’t get them to stop. I’ve tried all the combinations in the Estlcam settings and it just doesn’t work. The indicator lights up, but no lights on the controller light up. I gave up. After that, I tried to adjust the border dimensions, but I didn’t succeed either. I do not know why. I tried setting the spindle left-forward-down and all other combinations, I type in the dimensions, but that’s never it. It allows me to move briefly to one side and after that it is blocked.

I would like your help with these details. The CNC machine is homemade on an Arduino base with a CNC shield. I bought it assembled. The previous owner demonstrated the work to me and everything was fine. Obviously I don’t know everything about programming and setting up Estlcam, so I’m asking for your advice.

Thanx

Sounds like your endmill is loose and dropping out of the collet very slowly. Fasten the collet more and it should go away.

No, is not collet.

The forum has seen a long list of reasons that Z steps are lost. Here are three common checks beyond Philipp’s suggestion:

-

Check the grub screws on the connector between the lead screw and the Z stepper.

-

Check the lubrication on the lead screw

-

Verify that the Z federate is appropriate. You can upload the g-code file or post the top 25 lines in a post, and we can take a look.

If these all check out, provide more information about your machine, and a picture of your electronics.

The problem here is not mechanical, that something has come loose, but software. I tried 30 times today with some parameter names, which I thought they might be, and every time the same thing happens. He cuts the first three or four letterss at one depth, the next three at twice the depth and finally even deeper. The trick is that every time it goes down deeper, it shows -1mm on the controller. For some reason every now and then I get a new zero on the Z axis. I tried to upload a file, but I was not allowed.

Thanx

Can you provide the g-code file that is having the problem? What tools are you using to author the job?

Limit switch controller input pins need to be defined as limit switches in setup : controller : inputs (includes info on inductive sensor wiring). One input can be used for any number of NO switches wired in parallel. An “inverted” input can be used for any number of NC switches wired in series.

Travel Limits are machine coordinate limits and using them requires homing/working limit switches. Enter the abs command to view machine coordinates (rel for workpiece coordinates).

I agree with the others that any inconsistent positioning errors are a hardware issue. If the controller coordinate is -1mm that is what is in the G-code (right pane, e.g. G01 Z-1.0000 F600) and where the machine thinks it is. The only reason the machine wouldn’t be there is because something mechanical is slipping or binding… You’re not getting a new Z zero, the machine is moving to that coordinate, e.g. G01 X-65.5000 Z0.0000.

This file make my son in Aspire.

(---------------------------------------------------------------)

( Dateiinfo: )

(---------------------------------------------------------------)

( Dateiname: Profile 1 5mmm)

( Dateiverzeichniss = C:\Users\info\Desktop\Profile 1 5mmm.nc)

(---------------------------------------------------------------)

( Materialinfo: Alle Groessen in mm )

(---------------------------------------------------------------)

( X Laenge = 80.000)

( Y Laenge = 80.000)

( Z Laenge = 3.000)

( X Min = 0.000 Y Min = 0.000 Z Min = -3.000)

( X Max = 80.000 Y Max = 80.000 Z Max = 0.000)

()

( Parkpos: X = X0.000 Y = Y0.000 Z = Z1.000)

( Sicherheitshoehe: Z = 1.000)

()

(---------------------------------------------------------------)

( Programm Start )

(---------------------------------------------------------------)

%

N21 G17

N22 G90

N23 G71

(---------------------------------------------------------------)

( Erstes Werkzeug )

(---------------------------------------------------------------)

( Werkzeugnummer = 1)

( Werkzeugname = End Mill (6 mm))

( Vorschuebe )

( Fraesvorschub = 1016 mm/min)

( Einstechen = 254 mm/min)

( Drehzahl = S16000 U/min)

(---------------------------------------------------------------)

N34 M05

N35 M09

N36 G00 Z1.000

N37 T1 M06

N38 S16000 M03

N39 G00 Z1.000

(---------------------------------------------------------------)

( Konturname = Profile 1)

(---------------------------------------------------------------)

N43 G00 X4.618 Y13.462 Z1.000 M09

N44 G01 Z-2.500 F254.0 M07

N45 G01 Y27.962 F1016.0 M07

N46 G01 X20.618

N47 G01 Y13.462

N48 G01 X4.618

N49 G01 Z-5.000 F254.0 M07

N50 G01 Y27.962 F1016.0 M07

N51 G01 X20.618

N52 G01 Y13.462

N53 G01 X4.618

N54 G00 Z1.000 M09

N55 G00 Y36.517 M09

N56 G01 Z-2.500 F254.0 M07

N57 G01 Y51.017 F1016.0 M07

N58 G01 X20.618

N59 G01 Y36.517

N60 G01 X4.618

N61 G01 Z-5.000 F254.0 M07

N62 G01 Y51.017 F1016.0 M07

N63 G01 X20.618

N64 G01 Y36.517

N65 G01 X4.618

N66 G00 Z1.000 M09

N67 G00 Y58.350 M09

N68 G01 Z-2.500 F254.0 M07

N69 G01 Y72.850 F1016.0 M07

N70 G01 X20.618

N71 G01 Y58.350

N72 G01 X4.618

N73 G01 Z-5.000 F254.0 M07

N74 G01 Y72.850 F1016.0 M07

N75 G01 X20.618

N76 G01 Y58.350

N77 G01 X4.618

N78 G00 Z1.000 M09

N79 G00 X31.689 Y58.267 M09

N80 G01 Z-2.500 F254.0 M07

N81 G01 Y72.767 F1016.0 M07

N82 G01 X47.689

N83 G01 Y58.267

N84 G01 X31.689

N85 G01 Z-5.000 F254.0 M07

N86 G01 Y72.767 F1016.0 M07

N87 G01 X47.689

N88 G01 Y58.267

N89 G01 X31.689

N90 G00 Z1.000 M09

N91 G00 Y36.434 M09

N92 G01 Z-2.500 F254.0 M07

N93 G01 Y50.934 F1016.0 M07

N94 G01 X47.689

N95 G01 Y36.434

N96 G01 X31.689

N97 G01 Z-5.000 F254.0 M07

N98 G01 Y50.934 F1016.0 M07

N99 G01 X47.689

N100 G01 Y36.434

N101 G01 X31.689

N102 G00 Z1.000 M09

N103 G00 Y13.379 M09

N104 G01 Z-2.500 F254.0 M07

N105 G01 Y27.879 F1016.0 M07

N106 G01 X47.689

N107 G01 Y13.379

N108 G01 X31.689

N109 G01 Z-5.000 F254.0 M07

N110 G01 Y27.879 F1016.0 M07

N111 G01 X47.689

N112 G01 Y13.379

N113 G01 X31.689

N114 G00 Z1.000 M09

N115 G00 X57.909 M09

N116 G01 Z-2.500 F254.0 M07

N117 G01 Y27.879 F1016.0 M07

N118 G01 X73.909

N119 G01 Y13.379

N120 G01 X57.909

N121 G01 Z-5.000 F254.0 M07

N122 G01 Y27.879 F1016.0 M07

N123 G01 X73.909

N124 G01 Y13.379

N125 G01 X57.909

N126 G00 Z1.000 M09

N127 G00 Y36.434 M09

N128 G01 Z-2.500 F254.0 M07

N129 G01 Y50.934 F1016.0 M07

N130 G01 X73.909

N131 G01 Y36.434

N132 G01 X57.909

N133 G01 Z-5.000 F254.0 M07

N134 G01 Y50.934 F1016.0 M07

N135 G01 X73.909

N136 G01 Y36.434

N137 G01 X57.909

N138 G00 Z1.000 M09

N139 G00 Y58.267 M09

N140 G01 Z-2.500 F254.0 M07

N141 G01 Y72.767 F1016.0 M07

N142 G01 X73.909

N143 G01 Y58.267

N144 G01 X57.909

N145 G01 Z-5.000 F254.0 M07

N146 G01 Y72.767 F1016.0 M07

N147 G01 X73.909

N148 G01 Y58.267

N149 G01 X57.909

N150 G00 Z1.000 M09

(---------------------------------------------------------------)

( Programm Ende )

(---------------------------------------------------------------)

N154 G00 Z1.000

N155 M05

N156 M09

N157 M30

That looks wrong to me somehow. In Estlcam a negative Z would be a 3mm deep cut, and 3mm would be 3mm above the workpiece. I don’t know if those settings do anything, but that looks weird. I think I would try switching those.

In your code Z goes always back to -2.5 as the basis somehow, I think it should be 2.5 and might be connected to the quoted settings above. It could also be that you set the starting depth to -2.5mm for that part.

I do not now exactly how the gcode works, I am just making an educated-ish guess.

You’d have a lot more options and learn a lot more if you opened a vector drawing of those squares in Estlcam. I was surprised that Estlcam didn’t complain, but the g-code ran fine. All those M07’s (mist coolant) won’t do anything, Estlcam only supports M08/09 and M10/11 (output 1 and 2 on/off). The only valid Estlcam G codes are G00-G03; the G17 (plane), G71 (rough), G90 (absolute) in your G-code do nothing. All Estlcam machining is done with absolute workpiece coordinates.

Philipp: parenthesis are comments and don’t do anything. Starting from X,Y,Z (material top) zero, the G-code cuts a series of two pass (Z -2.5 and -5.0) square parts.

Thanx. I will try at weekend.

What hasn’t been mentioned in this thread is electrical. There’s no feedback loop with steppers, the controller won’t know about positioning errors caused by lost steps. Overloading the machine (high feedrate, deep DOC, low RPM) and mechanical (e.g. slipping coupler) or electrical issues (e.g. not enough current) can all cause lost steps. Your cutting foam at relatively slow feedrates would seem to rule out overload. You’ve also indicated there are no mechanical issues which leaves electrical. Because your step losses are happening when Z is retracting (highest load), my vote is not enough current (consistently) getting to the steppers. A loose electrical connection would seem more likely than a low driver current setting, a controller (default) setting, or a faulty driver.

It’s not obvious that the controller paths pane is 3D, that it can be rotated (same as the paths preview window) by clicking and dragging the mouse. I don’t know how useful it is, but if you rotate it to horizontal you will not see any increasing depth of cut and can confirm that whatever is happening is not caused or known by the controller program.

Thanks for your help. It seems that the feedrate on the Z axis was high and then the stepper “skipped” when lifting. I tried it today and it works fine. I will try it on more examples. I put one file that lasts 40 minutes, but after ten minutes the driver for X os turned off. After restarting it worked, but I will check the cables at the weekend. Thank you very much for your help and time spent in solving my problem.

but after ten minutes the driver for X os turned off

if the problem occurs again, perhaps the driver is overheated.