Good point. I neutered my post above.

The numbers in my spreadsheet are outdated, was only to show how I get the numbers I was talking.

I don’t have F&S for the LR4 yet, I’m going to mill the aluminum strut plates and than start testing things in the proper way!

I’ll share all my testing about in a future topic ![]()

OK, Ok…let me try asking another way.

Doug, when you cut the full sheet torsion box for your friend chaz, (albeit on a LR3) how long did it take to cut the pieces for the torsion box. Roughly? an hour, two, eight? AND should expect similar results on the LR4?

That’s what I need to know so that I can be assured that when I go screwing shit to the stage floor to bootstrap the table, I will have enough time to complete the job and clean up before the next person(s) come to use the space.

It’s a fair question. It’s been quite a while and memory is fuzzy. More like between an hour and two, not eight. LR4 should be able to do it in a shorter time, but I don’t have hard numbers on it yet, just a sense that it’s more rigid and can be pushed somewhat faster.

I just went back and looked at my video of cutting a full sheet capable torsion box table.

The cutting starts about 1 minute in, and ends at about 13 minutes in, and I think that playback was sped up by 10x, so, 12 minutes x 10 = 120 minutes. So two hours seems doable.

Thank you!! Now I can plan ahead and get this beauty all buttoned up and ready for Spring Musicals (Building begins in December)

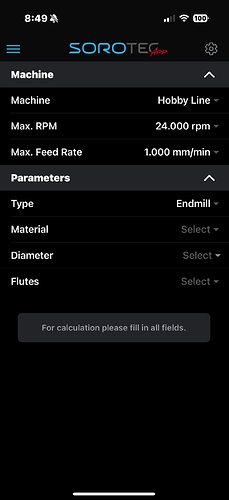

Machine is at the very bottom “Others” or “Misc” or I don’t know. All the others are the machines they sell. ![]()