Quick “one day” project of the weekend: my wife wanted a ceiling decoration in the living room for christmas.

She wanted a large-ish (60cm wide) ring to hang on the ceiling she could add some decaration to.

Something along those lines:

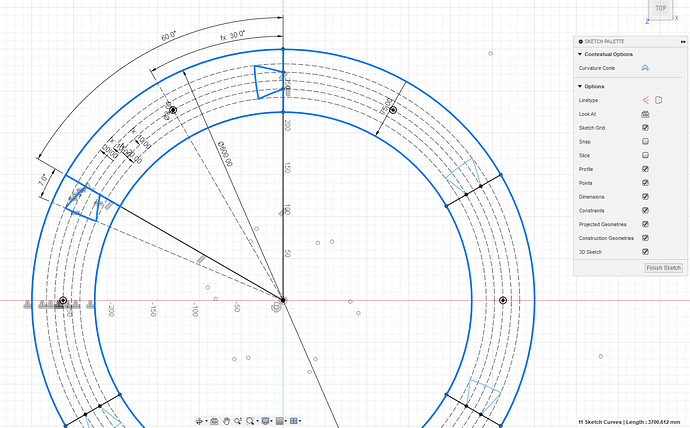

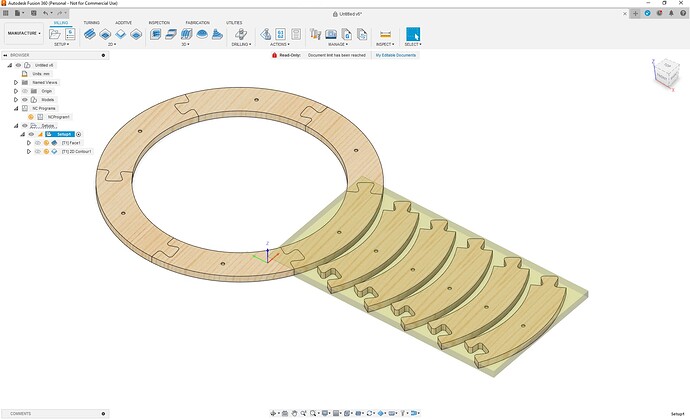

I quickly designed a sketch in Fusion360 to split the ring in 6 parts so that it could fit a smaller board

I made a few test cuts in particle boards to verify the fitting of the dovetails

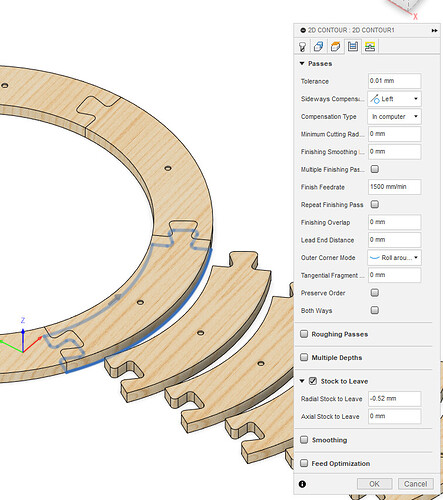

The tolerance is not built into the sketch, I just played witha negative “stock to leave” parameter until the fitting was right

To save on test material, I made the part smaller, and cut a single section I’d split in the middle and test the fitting with

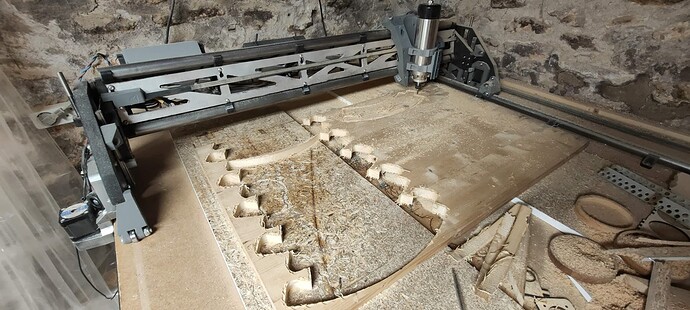

Once the settings were dialed in, I cut the 6 pieces in pine (never again… this material a complete nightmare to machine…)

Assembled the ring with a bit of “persusasion” ![]() and glued the pieces together

and glued the pieces together

Back on the LR3 for a “quick” surfacing.

Well… tbh this was the hardest/longest operation because I had several failures, the wires caught on the side of the table and the LR3 missed steps and went nuts (you can see the burn marks in the picture…)

I had to surface the whole thing 5 times in total >_<

After surfacing and a quick sanding, those joints look very nice ![]()

Wiped the ring with mineral oil…

Added 3 eyelets and fishing lines to hang it and voilà, it’s installed…

From request to product this was less than a day, and maybe 3 hours of work, I’m pretty amazed how the LR3 can enable those simple quick project, using just the stock I already had…

Now it’s my wife’s turn to work her magic and decorate the whole thing, i’ll post an update if/when it’s done ![]()