Hi,

I’m trying to better understand configuring feed rates, rpm etc for different materials.

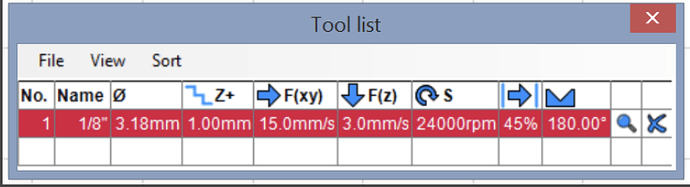

I used the settings from here - EstlCAM Setup - V1 Engineering Documentation

I can cut MDF cleanly with these.

When I apply these settings to a chip load calculator I end up with:

mm per second * 60 = mm per minute

15 * 60 = 900

mmpm * (rpm / no. of flutes) = chip load

900 / (24000 * 2 ) = 0.019

Apparently I should be aiming for the range - 0.10 - 0.18 for 1/8th bit on MDF:

So I appear to be a factor of 10 out. Am I missing something here?

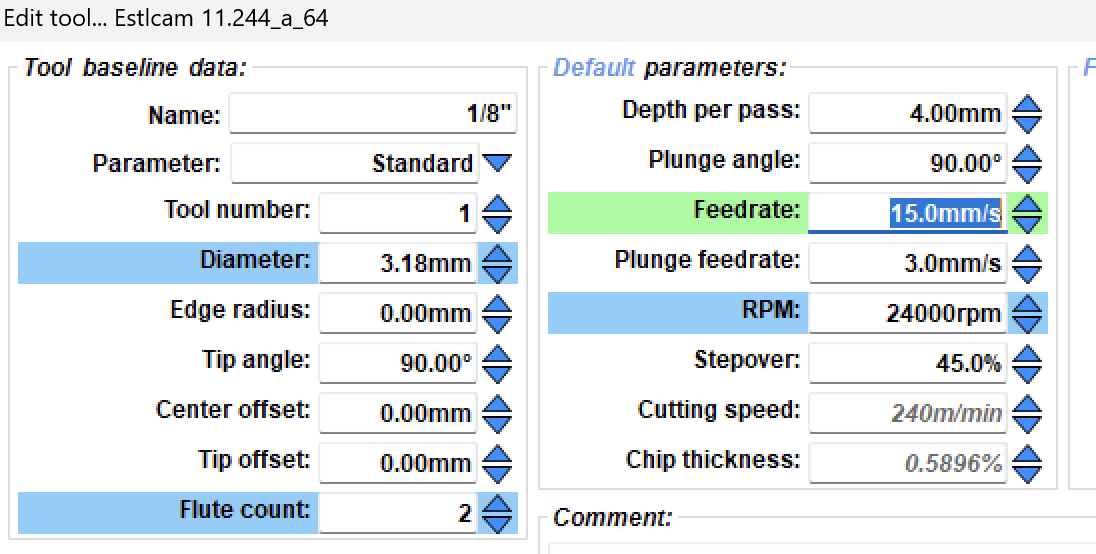

Second question is ESTLcam appears to be trying to help me with these calcs:

It is working out the chip thickness using diameter, feedrate, RPM, flute count:

What is chip thickness vs chip load?

Cheers,

Steve