Going to try my best to document this build, but it has started this weekend with the goal of my 3 adult kids helping me out. They missed out on the Voron build, because I was so impatient, and I really want them to get their hands and minds on this build. So, with that said, sharing the build with them will take priority, but I have enough from today to share.

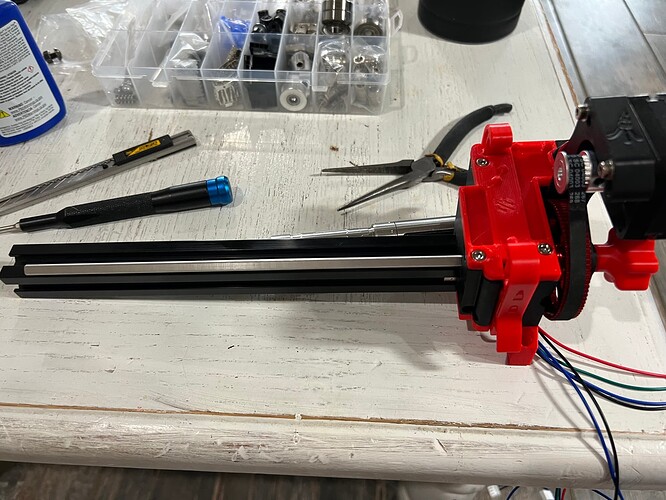

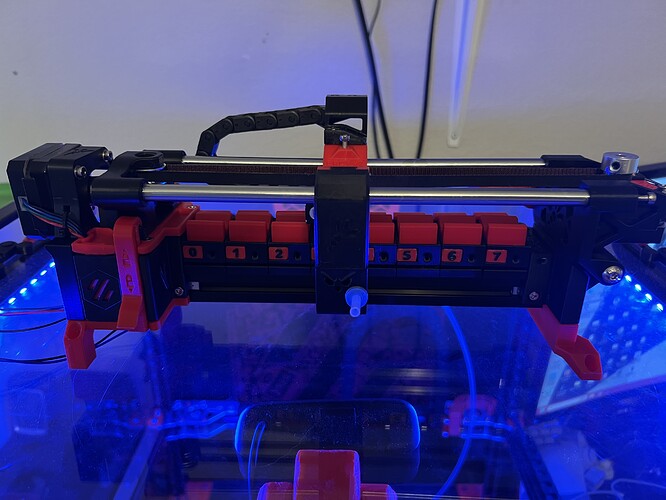

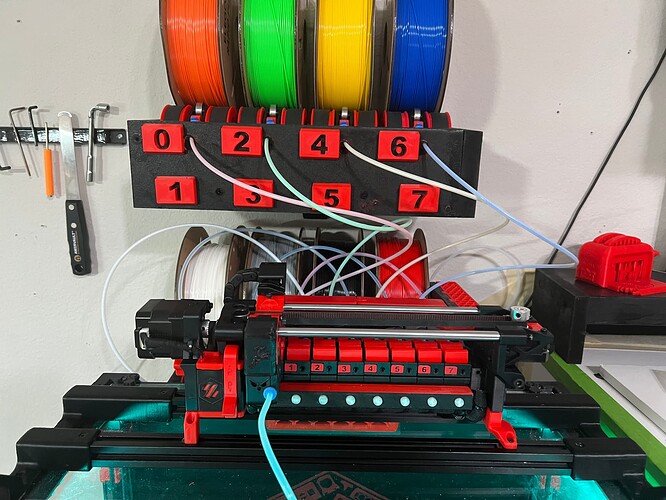

This is a Siboor ERCF V2 kit. It’s being printed with Polymaker Polylite ABS, in Black with Red accents, just like my Voron 2.4 build. The plan is to build this pretty much as the kit is presented. I’ll be doing the filametrix cutter on my stealthburner/galileo 2 extruder with 2 toolhead filament sensors. (The kit comes with hardware for 1 sensor, so I ordered some extras) Also will be using the Cottontail Buffer.

I found the Siboor github ERCF V2 page, which helped with matching printed parts, with what the kit was actually created from. This made parts selection much easier, as there are a few different options, and even 2 releases in the official ERCF V2 git. https://github.com/Lzhikai/ERCF-V2-Accessories

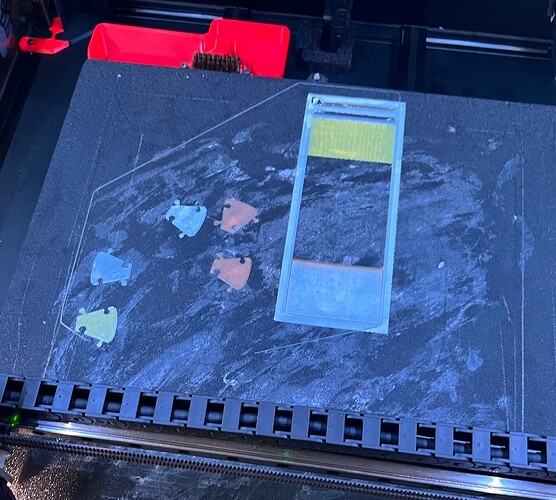

My Voron was built 2 years ago, but recently was given many, many upgrades (Aluminum parts, lightweight xbeam, etc.) so it was needing tuning, input shaper, and all that jazz. Following Ellis’ tuning guide, https://ellis3dp.com/Print-Tuning-Guide/ and with satisfactory shake n tune results, we set out to get dimensional accuracy with the only thing left to tune: extrusion multiplier/flow ratio. We used a couple prints to help fine tune this variable with the Polymaker ABS, [Printables][Printables] and settled on .92, printed with the recommended slicer settings and conservative speeds, and started printing.

We were able to finish the Gear Box section of the build, and are currently printing parts for the filament blocks, which will be started tomorrow. So far I’m satisfied with how everything is fitting together, and also impressed with the kit so far. Not many pics to share, but here are a few. More to follow.

Opinions and suggestions welcome.