I’m trying to use a 5/32 roman ogee chamfering bit. The issue is it plunges way too deep doing what I’m doing and I’m not sure why.

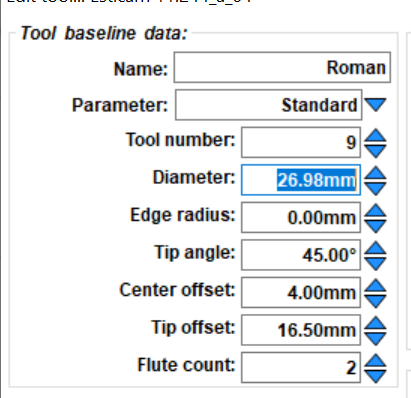

The box says it has a diameter of 1 1/16" or 26.98 mm. I measure the tip offset with calipers to get 16.5 mm.

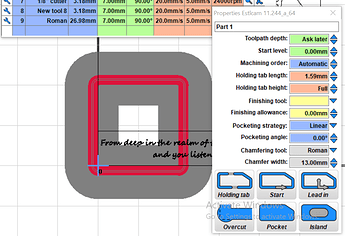

This is how I think it should get plugged into the tool settings

All I want to do is basically do a full depth chamfer to get the edge which should be close to a 13 mm chamfer. To test, just did a 2" rectangle with 1/4" bit then Roman as the chamfer tool.

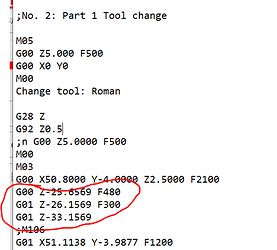

So why is it plunging down to 33 mm? Seems like it should only go down half the tool height to get to 13 mm, definitely not more than the tool height.

Estlcam is the software

;Created by Estlcam version 11 build 11.244

;Machining time about 00:01:19 hours

G90

M03 S24000

;M201 X1000 Y1000

;M204 P1000 T1000

M201 z50

G00 X0.0000 Y0.0000 Z0.0000 F2100

G00 Z2.5000 F480

;No. 1: Part 1

G00 X50.8000 Y-3.1000 F2100

G00 Z0.5000 F480

G01 Z0.0000 F120 S24000

G01 Z-10.0000

;M106

G01 X51.1039 Y-3.0851 F1800

G01 X51.4048 Y-3.0404

G01 X51.6999 Y-2.9665

G01 X51.9863 Y-2.8640

G01 X52.2613 Y-2.7340

G01 X52.5223 Y-2.5776

G01 X52.7666 Y-2.3963

G01 X52.9920 Y-2.1920

G01 X53.1963 Y-1.9666

G01 X53.3776 Y-1.7223

G01 X53.5340 Y-1.4613

G01 X53.6640 Y-1.1863

G01 X53.7665 Y-0.8999

G01 X53.8404 Y-0.6048

G01 X53.8851 Y-0.3039

G01 X53.9000 Y0.0000

G01 Y50.8000

G01 X53.8851 Y51.1039

G01 X53.8404 Y51.4048

G01 X53.7665 Y51.6999

G01 X53.6640 Y51.9863

G01 X53.5340 Y52.2613

G01 X53.3776 Y52.5223

G01 X53.1963 Y52.7666

G01 X52.9920 Y52.9920

G01 X52.7666 Y53.1963

G01 X52.5223 Y53.3776

G01 X52.2613 Y53.5340

G01 X51.9863 Y53.6640

G01 X51.6999 Y53.7665

G01 X51.4048 Y53.8404

G01 X51.1039 Y53.8851

G01 X50.8000 Y53.9000

G01 X0.0000

G01 X-0.3039 Y53.8851

G01 X-0.6048 Y53.8404

G01 X-0.8999 Y53.7665

G01 X-1.1863 Y53.6640

G01 X-1.4613 Y53.5340

G01 X-1.7223 Y53.3776

G01 X-1.9666 Y53.1963

G01 X-2.1920 Y52.9920

G01 X-2.3963 Y52.7666

G01 X-2.5776 Y52.5223

G01 X-2.7340 Y52.2613

G01 X-2.8640 Y51.9863

G01 X-2.9665 Y51.6999

G01 X-3.0404 Y51.4048

G01 X-3.0851 Y51.1039

G01 X-3.1000 Y50.8000

G01 Y0.0000

G01 X-3.0851 Y-0.3039

G01 X-3.0404 Y-0.6048

G01 X-2.9665 Y-0.8999

G01 X-2.8640 Y-1.1863

G01 X-2.7340 Y-1.4613

G01 X-2.5776 Y-1.7223

G01 X-2.3963 Y-1.9666

G01 X-2.1920 Y-2.1920

G01 X-1.9666 Y-2.3963

G01 X-1.7223 Y-2.5776

G01 X-1.4613 Y-2.7340

G01 X-1.1863 Y-2.8640

G01 X-0.8999 Y-2.9665

G01 X-0.6048 Y-3.0404

G01 X-0.3039 Y-3.0851

G01 X0.0000 Y-3.1000

G01 X50.8000

;M107

G00 Z2.5000 F480

;No. 2: Part 1

M05

G00 Z5.000 F500

G00 X0 Y0

;G00 Z35.000 F500

M00

Change tool: Roman

;n G90

;n G92 X0 Y0 Z0

;n G00 Z5.0000 F500

G28 Z

G92 Z0.5

;n G00 Z5.0000 F500

M00

M03

G00 X50.8000 Y-4.0000 Z2.5000 F2100

G00 Z-25.6569 F480

G01 Z-26.1569 F300

G01 Z-33.1569

;M106

G01 X51.1138 Y-3.9877 F1200

G01 X51.4257 Y-3.9508

G01 X51.7338 Y-3.8895

G01 X52.0361 Y-3.8042

G01 X52.3307 Y-3.6955

G01 X52.6160 Y-3.5640

G01 X52.8900 Y-3.4106

G01 X53.1511 Y-3.2361

G01 X53.3978 Y-3.0416

G01 X53.6284 Y-2.8284

G01 X53.8416 Y-2.5978

G01 X54.0361 Y-2.3511

G01 X54.2106 Y-2.0900

G01 X54.3640 Y-1.8160

G01 X54.4955 Y-1.5307

G01 X54.6042 Y-1.2361

G01 X54.6895 Y-0.9338

G01 X54.7508 Y-0.6257

G01 X54.7877 Y-0.3138

G01 X54.8000 Y0.0000

G01 Y50.8000

G01 X54.7877 Y51.1138

G01 X54.7508 Y51.4257

G01 X54.6895 Y51.7338

G01 X54.6042 Y52.0361

G01 X54.4955 Y52.3307

G01 X54.3640 Y52.6160

G01 X54.2106 Y52.8900

Anyone got any ideas?