My MP3DPv4 will be fully enclosed. Partially to keep dust out, but also so I can heat/cool the chamber.

I plan on having an 80mm exhaust fan for cooling the inside of the enclosure. What I can’t decide on is the following:

- Should I mount the fan in the lid of the enclosure and have it pulling hot air out (blowing out of the chamber).

- Should I mount the fan in the bottom of the chamber blowing cool air in with a vent in the lid for the hot air to be pushed out of.

I can see pros and cons to both. These fans are really designed for blowing air around and not sucking air out. If I was worried about keeping a heat sink cooled, I’d definitely be blowing. However, I think having the fan blowing cool air into the chamber could cause air turbulence inside the printer that could affect the print. There would be more movement. I also wonder if this would have negative effects on the part cooling.

Another plus to having the air being blown in from the bottom is that I will have the build plate lower to the bottom of the machine at the end of a print. This would put the build plate real close to where the cool air is being blown in and could help cool the bed faster.

Pulling the hot air out would cause less turbulence inside the chamber, but I think that would happen at the expense of less air turnover. Not sure if that is really a negative though.

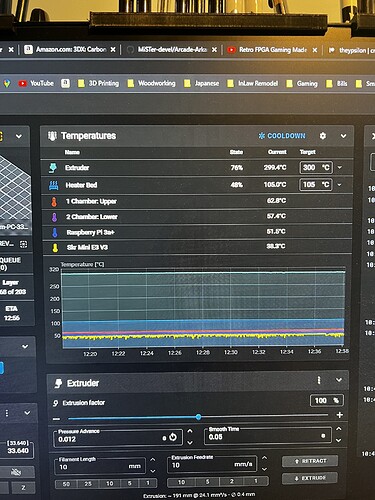

My current printer is enclosed and has an exhaust fan. For PLA, the fan pretty much just stays on. ABS, the fan cycles on and off a little, but mostly stays off. There’s not a lot of heat producers inside the current enclosure… Not enough to really trip the ABS “too hot” at least.

On the other end of the spectrum is the chamber heater. This is set up to blow the cool air across the small PTC heater. I have to do it this way to keep cool air flowing over the thermal fuse so that the heater doesn’t shut off from over heating. I will be bending a small metal shield to direct the air down into the bottom of the case to help diffuse it. I only really expect the heater to run on cold days to pre–heat the chamber. I do want to try printing materials that need a warmer ambient chamber, so we’ll see how that works.

Related to the above discussion, I could re-write my chamber plugin for octoprint so that the fan on the heater can be turned on independently of the heater. Then I could use the heater’s fan to pull cool air in at the end of the print to help cool the build plate faster.

The fan for the heater is pulling air from inside the electronics enclosure on the back of the printer. The electronics enclosure will have a 120mm fan blowing cool air into it to keep all the electronics cool. I expect some air from this fan to be pushed past the heater’s fan and core into the chamber as well, so there will be ‘some’ forced cooling into the chamber going on… even when the exhaust fan and heater is turned off.

My plugin is currently written with a min/max range for each filament type. This allows the heater to turn on until the min temp is reached, but then not turn the exhaust fan on until the max temp is reached. I expect most prints to run with either the heater running trying to keep the chamber warm, or the exhaust fan running trying to keep the chamber cool. Depending on the time of year, PLA will probably print with neither running.

Maybe I’m over thinking this.

TL/DR

My current plan:

- The heater/fan on the bottom blowing into the case with a diverter forcing it down

- 1 exhaust fan in the lid sucking hot air out