Hope all had a nice Christmas and New Year holiday!

A few days ago, I saw a more recent ceramic tile YT video, where a raw TiO2 powder mix was brushed on the tile before lasering. His recipe seemed simple enough and his results were outstanding. He was also able to run his 10W laser at much higher speeds than I’d seen before… 5000 mm/min and 45% power vs. the 1500 mm/min and 100% power I’ve always used with my little 2.3W Banggood laser setup.

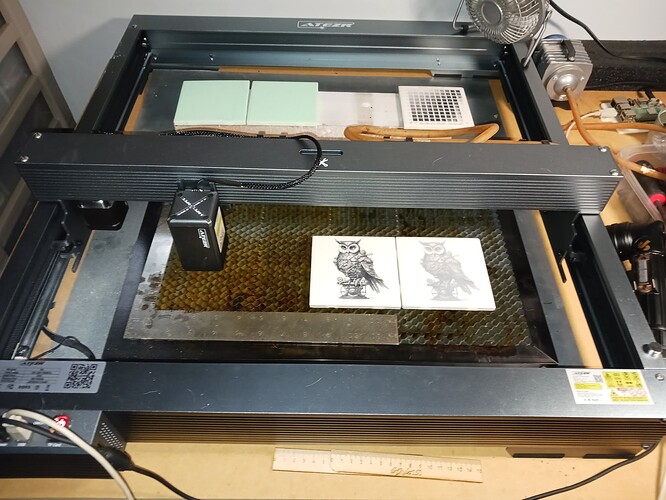

I also recently gave my little 2.3W Banggood laser setup to my son, as he’s started doing tiles as well. So during the holiday sales, Atezr put some refurbished laser engravers on sale and I was able to snag a P5 (same as my P20 20W unit but only 5W laser output) for just $139. More powerful than the 2.3W unit I had, for sure… but the spot size was advertised to be just 0.06mm x 0.06mm and I thought it might make a good candidate for ceramic tile engraving.

So I painted a few tiles with my trusty Krylon flat-white spray paint and started testing my new setup. The detail seemed good enough but I was less than impressed with the gray (not black), washed out look of the engraving… and left questioning whether the cool weather or phase of the moon had something to do with it.

The guy in the video said he attributed the gray to too little TiO2 in the paint however… and it sounded reasonable so I decided to give the TiO2 powder method another chance.

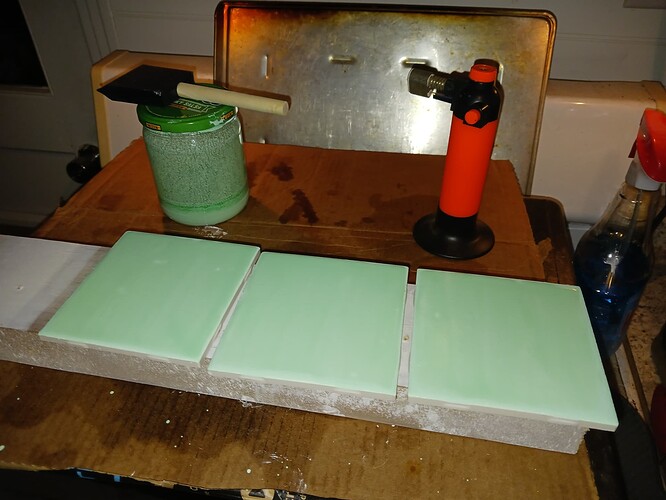

Having all the necessary ingredients already on hand from prior efforts, I was able to quickly mix up a jar of “TiO2 paint” following his recipe. By volume… three parts water, one part Elmer’s school glue, one part TiO2 powder, and a few drops of food coloring. And far less mess than I’ve made in previous attempts.

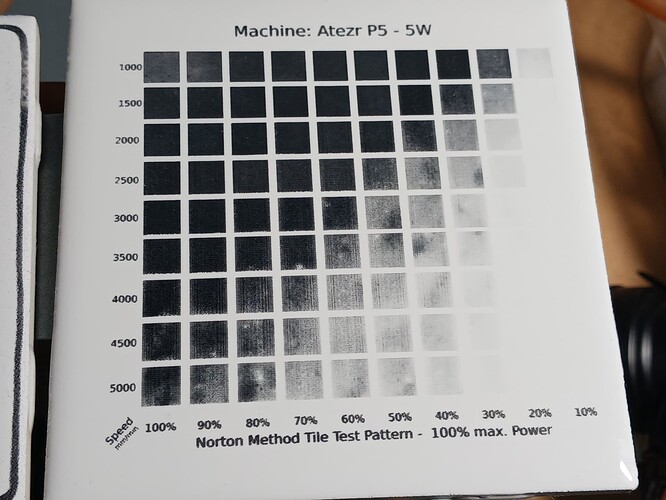

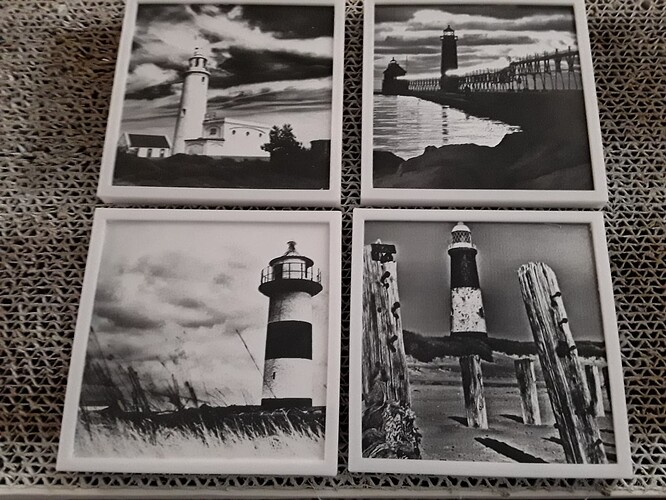

First things first, I did a test tile to see if my new Atezr 5W laser could run substantially faster… and give better blacks. Indeed, it could!

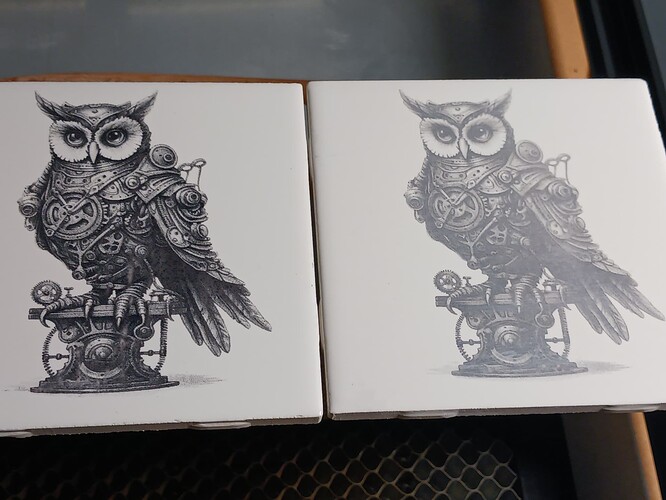

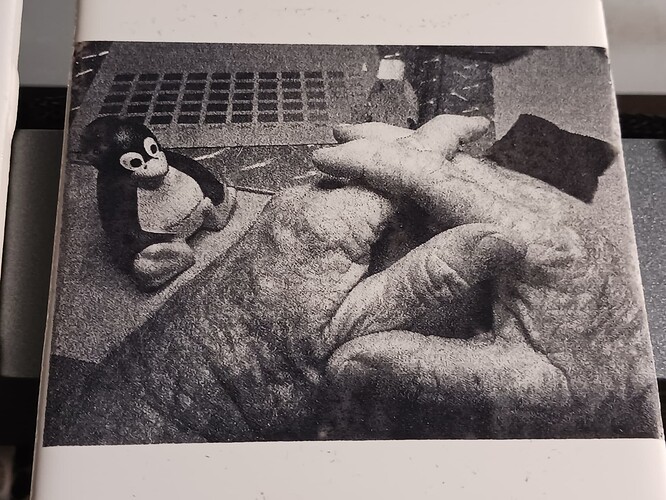

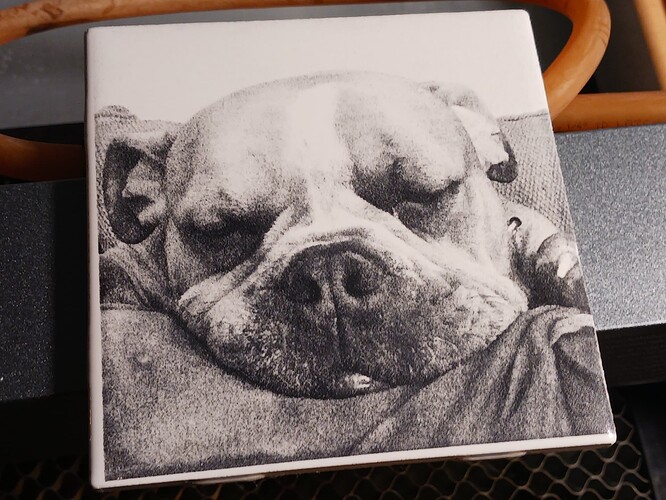

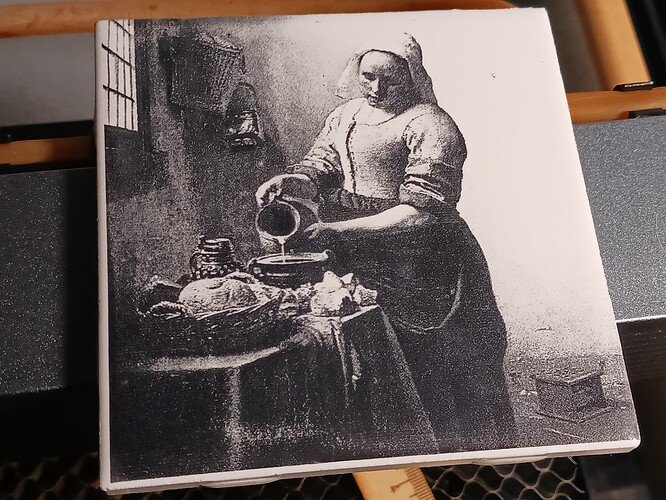

Then the owl – using 3500 mm/min speed and 100% power. TiO2 mix (left) vs Krylon flat-white spray paint (right)…

A couple of photos that appear a bit “grainy” but with decent contrast. The texture of the engraving with the TiO2 mix and higher speed does seem a bit “rougher” than all my previous tiles… maybe the reason for the “graininess”.

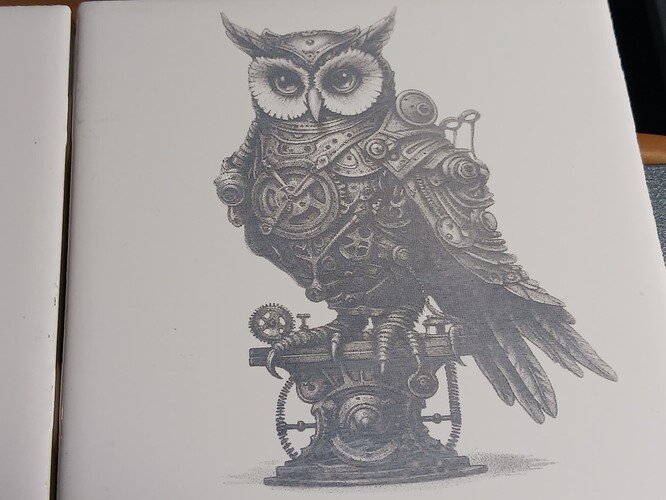

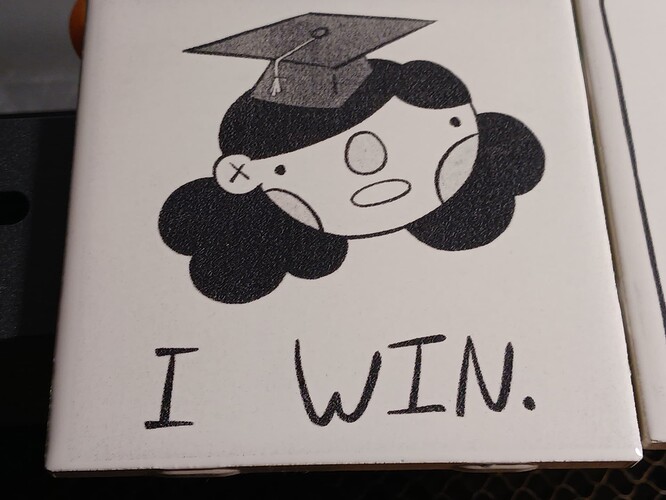

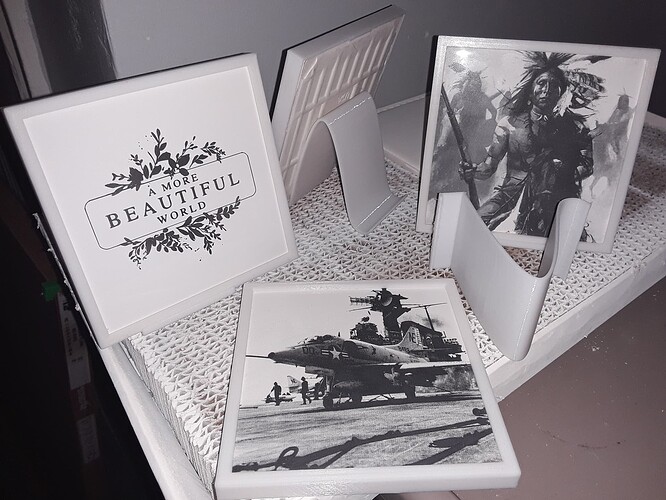

Finally, I’ve featured some of my talented grand-daughter’s work before. Now in college and doing well, it appears turning 18 and graduating HS last year made a distinct impression on her…

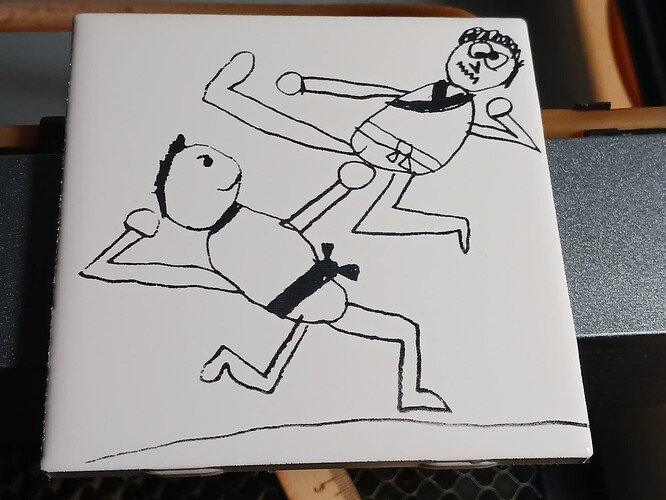

And, of course, I can’t forget my equally talented grand-son… who created this masterpiece some several years ago…

I can’t stress enough how pleased I am with this new method… a variation on the NWT and Ron Clarke methods I’ve tried before. I had given up on them after finding them just too inconsistent and messy. This method, however, seems to be working nicely for me at the moment… and I love the higher speed and easy water cleanup! Plus I can do it all indoors, where it’s warm…

The mix needs to be shaken vigorously before use… and the torch does a fantastic job on any/all bubbles.

– David