If you’re interested I can chase down a few links but here’s what I did a couple of months ago for my diode laser.

Taking a page from the Omtech 50W CO2 laser I purchased a few months ago…

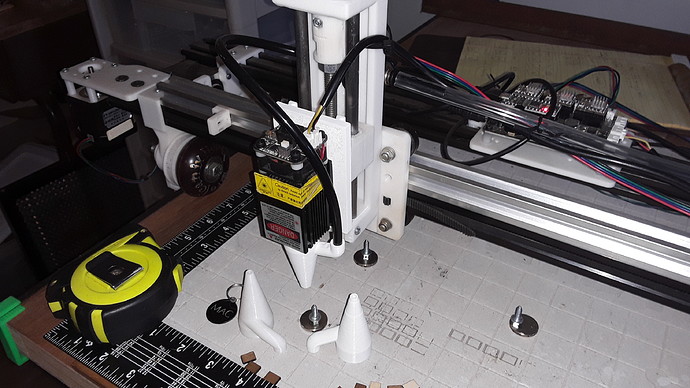

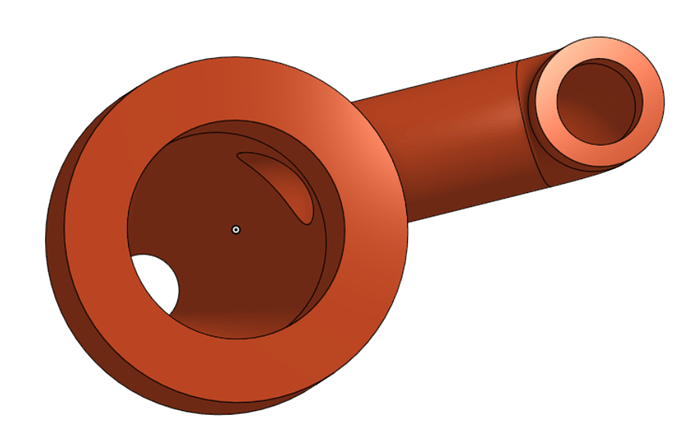

I devised a similar air-assist setup for my diode laser. Using Onshape I created a nozzle that simply friction-fits the screw-adjustable lens assembly of my diode laser module and accepts a length of 6mm air hose…

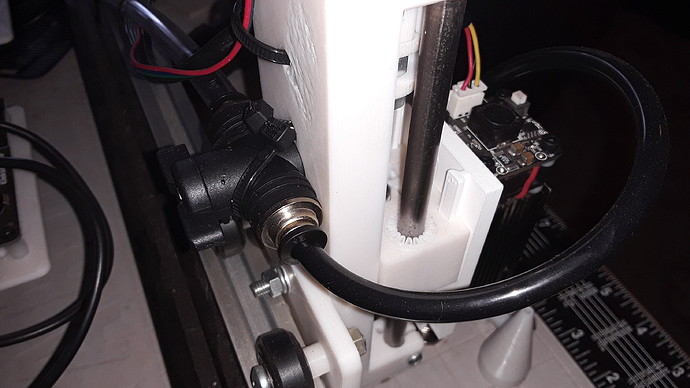

which loops around to a quick-disconnect ball-valve…

strapped onto the back of the Z-axis mount…

and then connects to an aquarium pump similar (though smaller capacity) to what’s provided with the Omtech laser machine…

The Onshape design file can be easily adjusted to accept a different diameter lens assembly and/or nozzle length and exit diameter…

and can be found here.

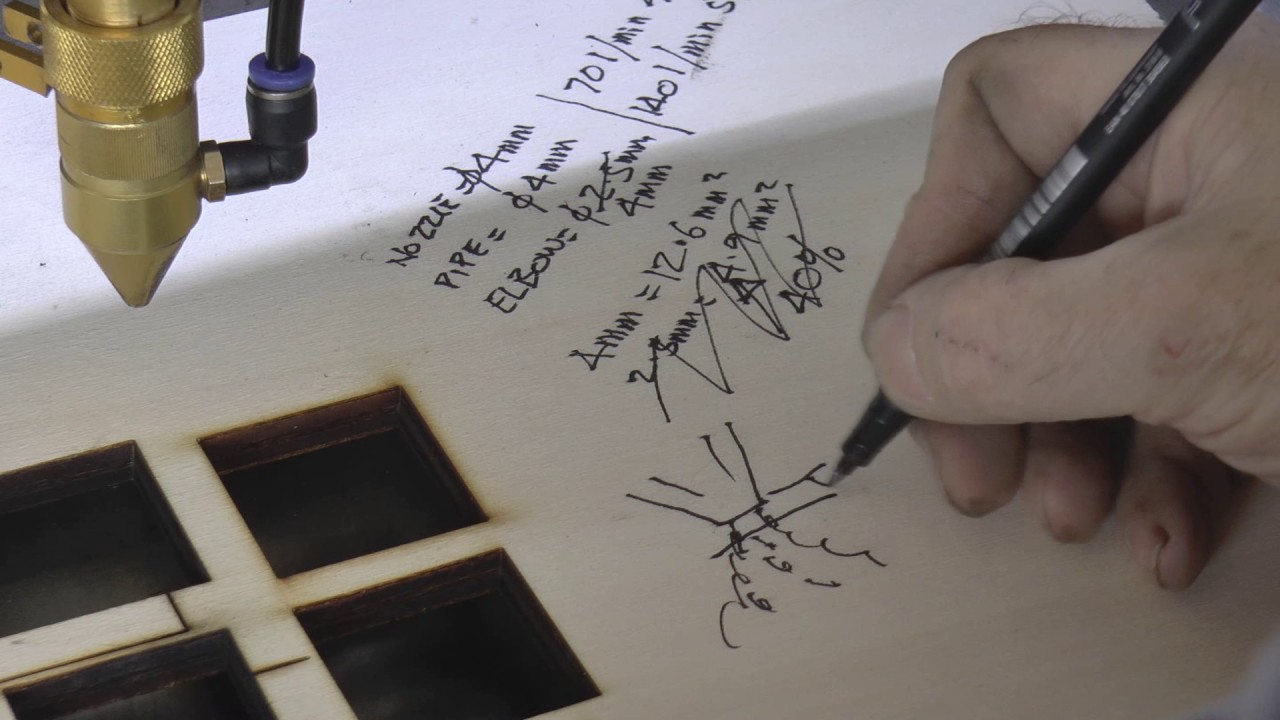

In use, the ball-valve can be used to adjust the strength of the air stream. For engraving, it’s best to use very minimal air-assist (just enough pressure to keep smoke from the lens) and open the valve fully to cut through materials. Russ ( SarbarMultimedia has a zillion videos (mostly CO2 but same air-assist setup) that talk about “everything lasers” and this one might help…

Have fun.

– David