I hope this is the right topic for this, if not, please feel free to move it!

I got interested some time ago in canbus and went through the motions of setting up my V4 printer. It was brutal to get it going and in the end, it didn’t give me the flexibility I was looking for.

There were a few requirements I felt I absolutely needed in a bus type system for my printer:

- It had to be easy to use and not require more than one mcu to run/flash/update.

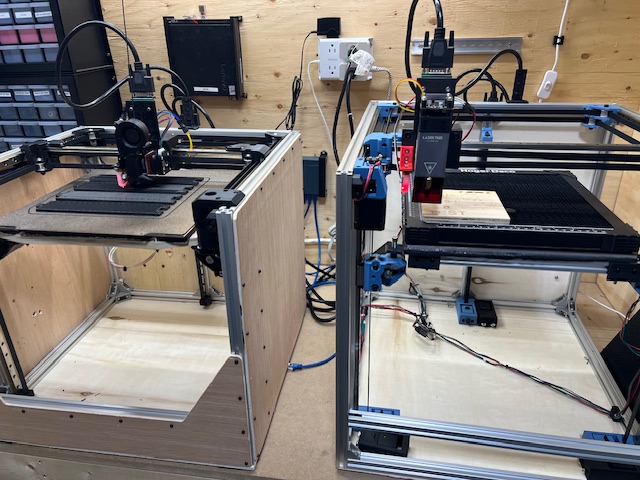

- I wanted some kind of tool changing ability for ease of maintenance and to be able to switch to a laser on any of my machines.

- I had to be able to draw new/remix/use existing parts for MP3DP without having to build anything crazy.

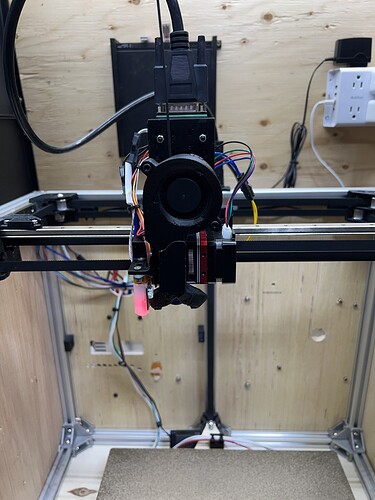

- No more than one cable going to the x-carriage.

- Connections had to be super easy.

- No other changes required to the MP3DP other than at the x-carriage.

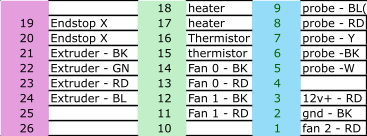

When I counted up the number of wires that need to go to the printhead, I came up with 19 for the 3D printer and another three for my laser including a 12v power supply, ground and pwm for a total of 22.

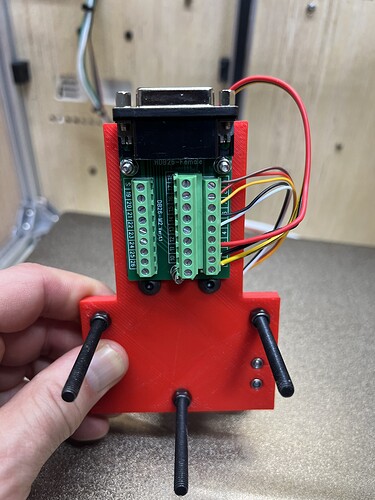

Enter - Davebus™

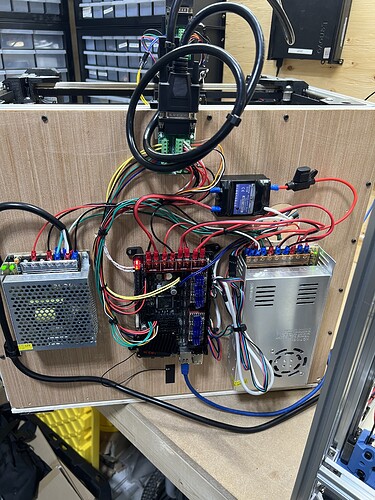

First - I looked for a bundle of wires that came to at least 22. After using RJ45 breakout boards on my LR3 I looked around for a suitable board and cable for this. I decided on the DB26, that would give me what I needed plus 4 other wires for future use.

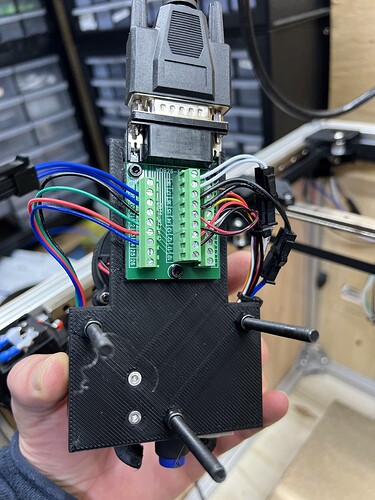

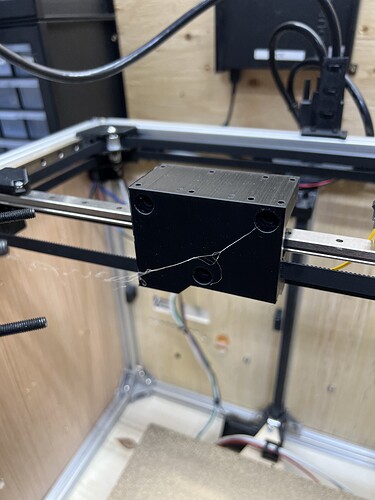

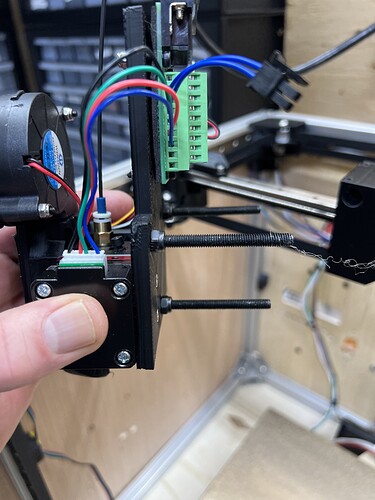

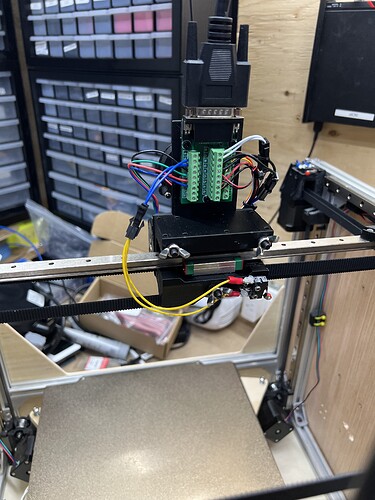

Second - How do I attach/un-attach the tool to the x-carriage. I thought I would like some kind of automatic process for this, but after going down the rabbit hole of what is available on the internet for them, and having a good night’s sleep on it, I decided it would be easier to come up with a manual system. I drew the tool plate with room for the breakout board on the back with long bolts that would go through the x-carriage to hold the tool tightly. Butterfly nuts on the backside are easy to remove as well as easy to keep tight! I redrew the x-carriage to accommodate the toolholder and the nuts on the backside. The nuts also help center the tool plate and keep it from moving.

Wiring from the M8P for the x-carriage all goes to another DB26 breakout board on the back. I prewired everything for the extruder and the laser at once, the tools only use the wires they need with 4 wires left for future tools.

The x endstop is wired onto the x-carriage and connects to the toolholder with a clip. This was the only way to keep requirement #6 that I could come up with.

I have been running this now for a couple of weeks and have had no problems. Still working on the klipper config for the laser, but looks promising!

DB26 Terminal $13 CAD on Amazon

DB26 Cable (male to male) $36 CAD on Amazon

What do you think?