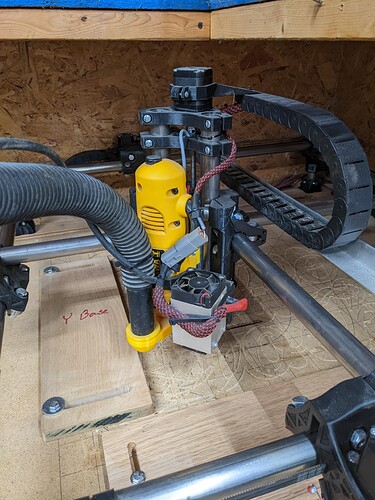

Just have to finish the Z axis power and Vacuum Hose

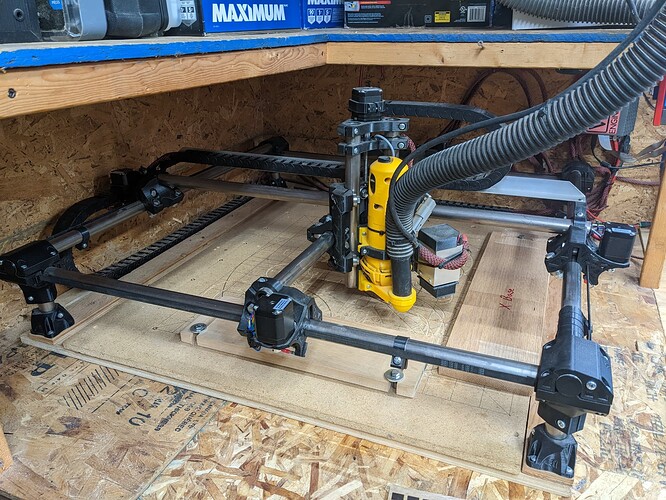

Short and Stout, love it!

kyle did you use the burly c plans as i see ure using emt conduit did you find the 3/4" conduit to be super tight in the feet?

I didn’t have too much trouble getting the feet to fit. My only real “issue” was the nuts didn’t stay captive and had to use a flat head screwdriver on the nuts to hold them while tightening. Other then that the design could not have been better! Super impressed by all the hard work that’s been put into this by the v1 team. There support is amazing too. Kudos v1!

Just a quick update,

I've added:- spindle speed control for the dw660 using a router speed controller

- an endurance 3.5watt laser with a mount on the dw660, and dust covers

- modified the x y endstops to have zip tie brackets to prevent me from accidentally knocking them off all the time.

- Octoprint on a raspberry pi with all the custom commands I need for CNC

- And old Android TV I am using to control octoprint in the shop

- Bed sizes input to prevent time out during homing

- M73 enabled for octoprint

- Aayrns Laser fix

- Software end stops enabled for my bed size

I have been using and slowly making changes to this since last year.

Here is my thingiverse collection of items I have printed for the MPCNC, some of which are custom items I have designed, but huge thanks to the group here for the troubleshooting and support!

Pretty sweet seeing the progression.

2024 Update!

I have updated to a Jackpot Board

Made a new [PSU enclosure](https://Custom v1 Control Box - Jackpot CNC Board with Meanwell PSUs)

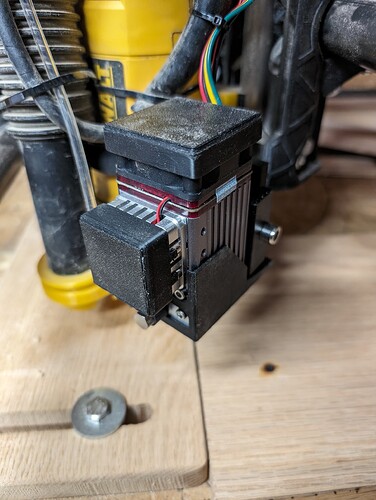

Upgraded from a 3.5W Endurance Laser to a Neje 10W a40640

Designed a new mounting solution for the Neje Laser

Designed a new mounting solution for the Neje Adapter board

Designed new covers for the Neje Laser

Check out my collection for all the mods from Printables:

Printables

Looks great nice enclosure there.

How was the leap into jackbox land ?

Still trying to figure it out a bit, but I’ve run some simple test jobs. The physical moving from the Rambo 1.4 to the Jackpot was pretty good. I had a couple issues with the config (silly mistakes).

I’m still working on the finding an ideal workflow. I did like using my Raspberry Pi and Octoprint as I could have way more macros, and keyboard jog, and web camera. I’m hoping I can figure out something with CNC.JS setup to avoid needing to have a laptop out in the shop and running back and forth with it.

I have to clean up the wiring still inside the box from the Rambo but thats a future project once I know things are working consistently.

Thanks for the explanation.

No problem if your switching and have any questions feel free to reach out!