Home a day late. I just looked at my machine. I have a Makita RT0701C clone (Carbide 3D) router with a 65mm Primo Makita mount. With your larger router, there are two areas to look at. The first is where the “mushroom” head potentially intersects the bolt. The issue is here:

My clearance is tight at this point with only a couple of mms to spare. Placing a photo of both routers on top of each other in photoshop, the mushroom heads look very similar in size. Whether you have to add additional space for the head will depend on its geometry, but if you do, it won’t be a lot.

The second close place is where the mount intersects the tubing when the gantry is pushed against the trucks. Here is a photo looking down.:

There is probably 5mm of space left using my Makita (65mm) mount.

Looking at these two spacings, you should be fine if you pick the size you want your cutting area to be, then add 3/8" (10mm) to the measurements before feeding them to the MPCNC cut calculator.

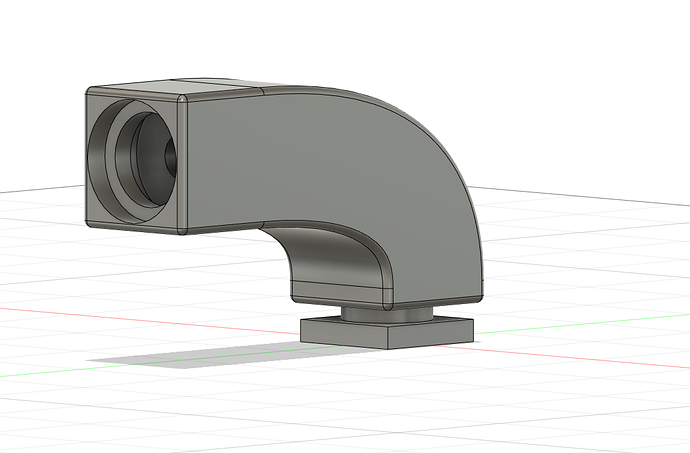

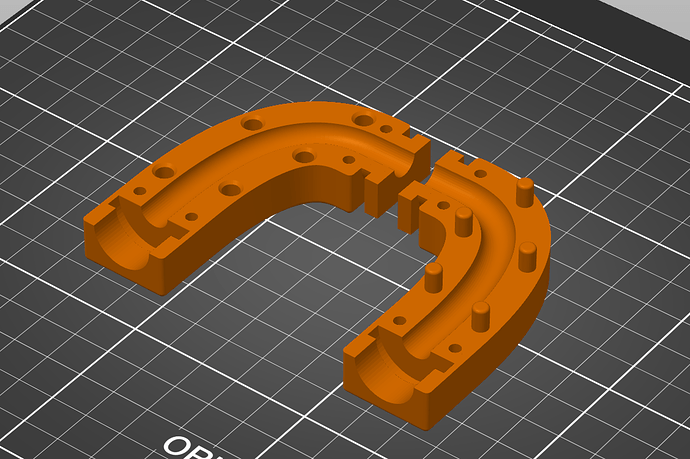

As for the fitting for the router, it could not find the model, but it is pretty simple:

Simply crack open the case at the top, slide the rubber fitting out of the way, sandwich the cord between the 3D printed parts, and reassemble the case to hold everything together. Personally, I did not even remove the rubber fitting, just slid it down to the plug end. That way I can reverse the process if I want to use the router more traditionally in the future. If you like, I can model up an STL of this part for you.

As for the mid-span supports, you will only use a few inches of rod for each support, and you will only need them on the long sides. The mid-spans you find on Thingiverse will be modeled for a specific threaded rot since you will need a nut trap for the inside of the tubing.

Awhile back Ryan ran some tests comparing different tubing. Over a 4’ length (longer than you need), he was getting about 1mm of flex with stainless steel tubing, and 0.5mm in DOM tubing. This movement was with a 10lbs weight applied, which is more than your Z axis and router will weigh, and your machine will split that support between two tubes.