Seems like you’re breaking your own rule LOL

Oh, dear lord. I’m not even an engineer, and that makes my teeth itch. Of course, my next big project, after moving our application to the cloud, is basically rewriting it as a massive revision control system for tolerance analysis… ![]()

Had some long and involved discussions with real engineers about versions, revisions, documents, drawings, illustrations, sources of truth, etc.

This is going to make future troubleshooting a nightmare. No way to know if the user has the new resistors or not. Most of the time its faulty wiring. But will be harder to prove when we dont know for sure which board they have

We’ll see, that image still shows v1.2…it would be a very poor choice not to change that.

add .1 with a Sharpie to the board before you ship it out lol

That is honestly not a bad idea.

I can’t find the original thread where this was worked out. Is this correct?

Seems right.

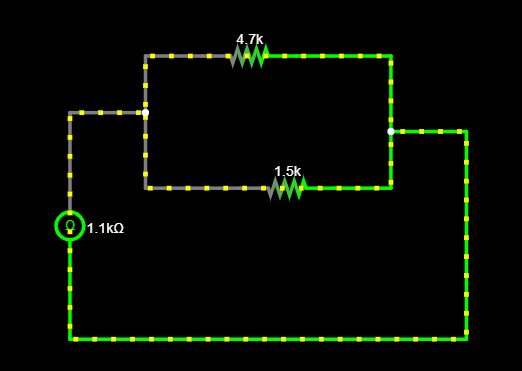

Anyway, lowering the pullup resistor value is the answer. I used a second 4k7 on my MKS board having the same issue and it worked (I think I listed it as 470 in my thread) because it was basically halving the series resistance.

We’ve been addjng a 1k5 resistor in parallel with that 4k7 which I get about 1k1 effective resistance, so this is a little higher than the “known good” solution, but still in the ballpark.

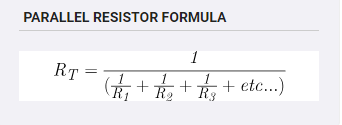

Someone remind me if my math on parallel resistance isn’t right… 1÷((1÷R1)+(1÷R2))

The resistance value just has to be high enough that the pin will still drop to logic low when the switch is closed. Any higher than that is basically power/current saving while the switch is closed. As a result the boards with the 1k5 will draw a little more power than the ones with the 4k7.

Given that it is still an intermittent problem, 2k2 or even a 3k3 substitute would almost certainly solve it (just choosing E12 series values.)

We’ve been addjng a 1k5 resistor in parallel with that 4k7 which I get about 1k1 effective resistance

Your math looks right according to whoever wrote this code ![]()