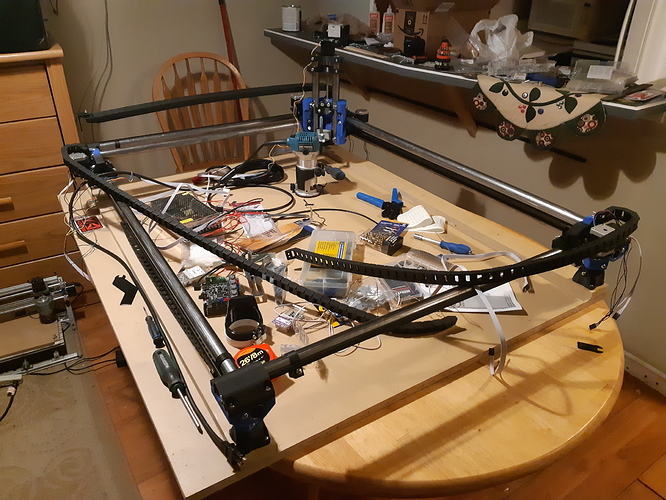

Freshly printed drag chain holders. Printed in PETg for strength and a.little flexibility. You might notice that the holes for the drag chains are oriented differently. I thought I had ordered identical drag chains, but on closer examination the X and Y drag chains are different and have the mounting holes set up differently. I can share the Mounts if people want, I suggest you modify them to suit yourselves

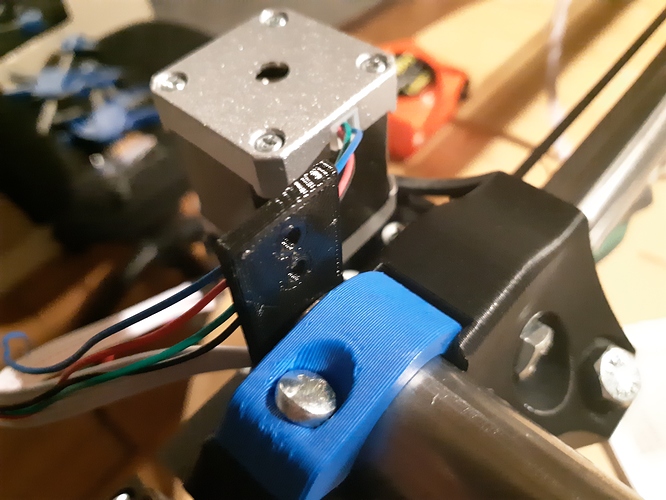

X gantry at the Y motor. This holds 2 chains, one to the control box and the one out to the core

The core end bolts to the clamp at the provisions provided.

Y gantry at the X motor

The work area getting cluttered again. Drag chains test fit. Nothing for the control box yet, and I need to extend the wires and attach cable to stop switches.

4 Likes