I also leave them pretty flat and place them into a fireproof metal thingy.

Agreed. I like linseed oil as a wood finish, and have used it often. Never had a fire, but I am very much aware of the risk. I have deliberately set a fire with oily rags in a steel bin to show my kids how a careless action can cause a disaster. (And they didn’t want any oiled wood in the house for months afterwards!)

I hang them completely flat on the rim of the bin or leave them flat on a bit of cardboard - one layer only. They won’t get hot like that.

I have had a neighbour’s house burn as a result of this as well - if you are using lots of rags (I don’t understand why you would because one “loaded” rag is enough) a fireproof metal thingy is only fireproof if there’s no oxygen inside it or limited amounts, and it can still get really hot till the oxygen burns out, so water in the bin won’t hurt either!

For a quick water resiliant, take pva glue, water it down 50-50 with water. Mix well and brush it on all surfaces especially edges. A couple of coats drying in between. Redo surface after scarring will help keep it good. You can paint over if you want later.

Linseed oil heats as it dries and cures. As do most oil-based finishes. Using it as a finish on a table or something would be frustrating because it takes months to fully cure. Functionally it will be dry in a week or so. Which is why you are probably not seeing very good waterproof qualities. To apply it you need to apply many coats over a number of days to achieve any real level of surface protection. The new coats will re-wet the previous coats and bind to them. So if you do get a water ring on a surface you can just rub more finish on and it will go away. Which is neat. Danish oil is a much more easy to use alternative. It has a similar look but is mixed with a bit of oil-based polyurethane to reduce its functional dry time to a day or two. It is also a simple wipe-on finish and can produce good results in 2 or so coats. Danish oil penetrates well and gives you most of that amber look you would get from linseed oil but has a cap on how many coats you can apply before you are just making a gelatinous blob on your work surface.

All of that said if you want a great finish get some Rustoleum enamel from the hardware store and roll it on. Thin it out a bit with mineral spirits and run it through a strainer first though. Use a fine nap roller. That will soak into MDF bonkers well and be incredibly smooth and resilient. Oil-based polyurethane would also be good. Poly is a very safe finish as far as dust goes. Enamel is not. If you want to talk about how different colors are different kinds of unsafe oh boy I am your huckleberry on that.

If you are trying to keep MDF flat you will need to coat all of the sides. A simple, cheap, and easy way I used to do it in school was to water down some wood glue and roll it on the whole thing. That will seal it plenty well for plenty long enough. This is also a great way to prime MDF for paint so it doesn’t soak up as much. You could also just use a primer. But I was in college and primer costs more money than glue.

Water-based poly isn’t worth using on anything in my opinion. If it is worth finishing it is worth using something better than that. Might as well shrink-wrap it in cellophane at that point.

Shellac kind of sucks because alcohol will re-wet it. So if you use any sort of cleaner, solvent, whatever, that is alcohol based. It will get into it.

Rags used with oils should be kept in a fire-proof container that is emptied daily.

That’s what I did when doing my suction table. Worked quite well.

Sanding sealer works great as a first coat or two, especially on the ends. Then you can poly or paint for final seal

I have a quart of Sanding Sealer i bought ages ago and never used. Might give that a shot. And i have paint that i got matched from the printed parts so may just use that and paint it…All but the strips im going to put for the “spoil board” not concerned about stuff getting set on that. mostly its the edges and each end that things tend to get set on lol. My top is oversized even for my large 50"x98" work area. Trying to get some more drawers finished for the cabinets that the top is mounted to so i can get some stuff a little more organized lol. All seems to be a long work in progress.

What did you end up using?

Haven’t done anything with it yet unfortunately. But need to soon. Its been COLD here the last few days. Plus tons of stuff going on and trying to dial in my V4 printer in spare time. But I’m hoping to get out there this afternoon or tomorrow and clean it all off and probably do some test areas of different ideas and see which works best for me. Ill report back once i make a decision.

Coat it in silicone caulk. That, and/or keep it away from water.

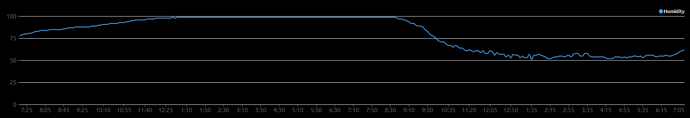

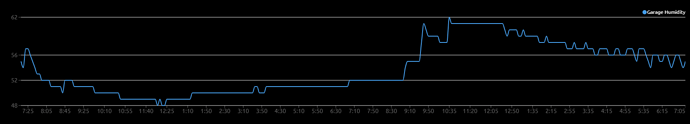

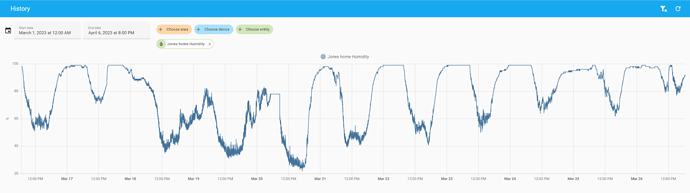

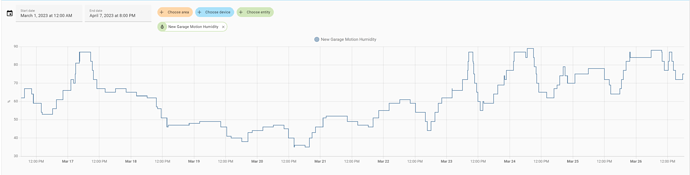

My house was built in 67. No insulation in the garage and no plastic under the concrete. The floor sweats often and it doesn’t matter doors closed or not its humid lol.

Garage Sensor…

I got lucky, the garage has ac. ![]()

Ok, now I’m jealous…

Me too!

Mini split for the win. Easy to install, low power usage. Best thing I’ve put in my garage so far.

I would LOVE to do that!!! But its a lot more than just installing the mini split here. Would have to insulate for sure. And would probably need 2 units as I have basically 2 - 2 car garages. There was the original built on the house. Then in 2003 they added another at the end of the original. The door opening is still there walk though it to get into the new section. I’m already fighting cooling the house as it is. And now with good ole Florida Power and Light my bills run in the $700 range in the hot summer. So lots of other things need to be taken care of before I can justify cooling the garage lol.

How waterproof do you want it? If you really want to go all in, give it a coat or two of thinned epoxy, then a final coat or two of spar varnish.

Personally, I just used multiple coats of a quality poly when I put a water resistant coating on my aquarium stand. It wasn’t made of MDF, but I still wanted it sealed.