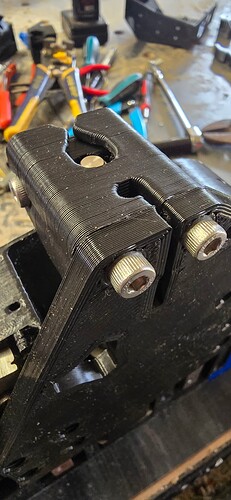

Admittedly, i haven’t looked through here for the subject. But based of the printables listing and no “makes” before the one i just posted, these are still untested. Well i printed them and will be testing them. So far all the holes line up, and it activates the z endstop. Any tests that are desired post them here and I’ll try to accommodate.

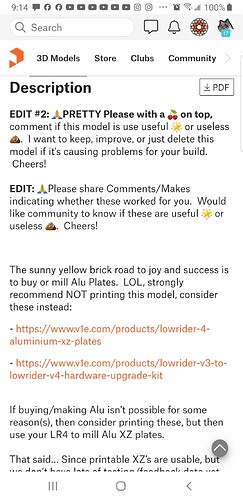

Adequate to build up a machine, mill aluminum plates, then rebuild the machine.

Inadequate for everyday use.

There’s a reason the printed plates did not survive the beta program into release.

Understood completely.

Thank you @spsully2582 for trying these out and sharing your experience. Fwiw am using flanged button head bolts and thread locker 242.

Agree with @MakerJim even though my friend still has densely thick wall printed PLA XZ plates on the LR4 RC3 I helped build, which doesn’t have much runtime on it, so too early to comment on those. I thought @SupraGuy had PLA XZ plates too, maybe that was just during Beta?

I tried to set expectations in the model description…

Am curious whether the PLA XZ are good enough for LR4 “Light” and help enable more folks to get started on their MPCNC journey? Hopefully feedback will help inform where the MPCNC TNG ends up…

Probably as a starter. To use an analogy…

You can put 4x “donut spare” tires on your car and drive it around just fine.

Generally, though, you want to have the correct wheel/tire on your vehicle.

Same with your CNC.

no way am I driving around on my cnc no matter what plates are on it.

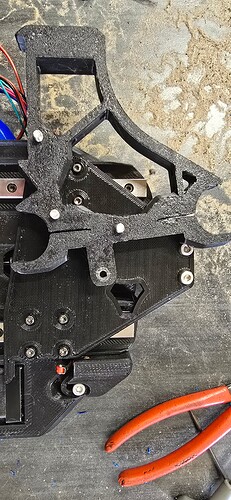

My machine that I built for the beta/RC build has printed XZ plates. For the larger build, I bought aluminum ones. I actually want to try some specific tests for the printed plates.