Thanks! I guess I need to get out more, ASA and HIPS were unknown to me until this AM.

I think with the year we have had we could all use to get out more

But there is always new filament coming out, I spend a lot of time on all3dp, it’s probably the only reason I know about them

Ain’t that the truth? ![]()

I am new to 3D printing but i did read up on the physical properties of the main, different filament types the last couple of days. A couple of sources agree that PLA will degrade with time especially when exposed to sunlight. A friend of mine did produce a “surf hook” for hanging surfboards and after 6-12 months he got reports of broken hooks. Probably due to PLA degradation.

Manufactures of 3D printers use PETG for their machine parts and i reckon there is a reason why? The “official” recommendation for machine parts is to use ABS(+), ASA and off course, carbon fiber enhanced filament.

i am planing on using PETG for the Lowrider V2 parts.

I had been looking at ASA too but there is only CCTREE ASA at a high price available in the country i live in. As CCTREE PLA and PETG i did use varied from unusuable to “a pain to use” (regular nozzle jams, even with a 0.6mm nozzle) i did order ABS+ instead.

This might be of interest:

[https://www.youtube.com/watch?v=n0GdrC21qWw](https://Filament Stress Test)

It’s not about the strength or durability, it about rigidity. Abs and petg are not nearly as rigid as PLA. keep in mind most of these parts are only required to hold a few pounds of force (probably less then any surfboard weighs, but I don’t surf so maybe I’m wrong). The key is that they can not move at all when that force is applied… you are correct that pla will degrade when exposed to light, heavy moisture, and heat. Luckily most of those are not present in the garages and basements where most mpcnc live. If you are worried about that there are other ways to prevent that degradation. Such as finishing your pla parts with UV protective sealant.

As a side note, most 3d printed parts that are printed out of petg are not frame components (most are fan housings, knobs, guides, clips, feet, etc) in these applications it’s better to have a material that is more heat resistant, then rigid, and if the part flexes it doesn’t really matter (or even desired, my 3dp feet are springy to dampen noise and vibrations)

If you want to print with petg go for it! But as someone with a few years of 3d printing expierence under their belt, I would say it’s a lot more about picking the right material for your application then picking what others are using for a different application (I would recommend abs for your friends surfboard hooks, they don’t care about heat or moisture and are more resilient to uv light. And even if the hooks come out just a touch warped it won’t matter  ).

).

One last comment, when you watch that stress test notice there is more going on then just the weight applied. Notice that the PLA hook didn’t warp or bend or stretch. It held its shape until it broke, that’s what you want for the mpcnc. The others stretched and warped before giving out, that will cause deflection during milling.

There are a lot of PETG machines out there. If you prefer it, then go for it. I think the general recommendation was just to add a few more perimeters, but we’re all learning here.

Thank you for this in-depth explanation why PLA is recommended. As i stated before i am a 3D-Print Noob but did read up on the different material types available. I am aware this doesnt replace printing experience.

I am living in the tropics and currently we have 80% humidity around here and it will get very sunny as soon as the rain season is over. High humidity does effect at least the filament “a lot”. If i leave PLA in the printer over night, even when AC is on (Humidity -20%) i find that the PLA did break on the next day (approx after 5 hours).

The printer will rarely be exposed to direct sunlight but i rather would like to use a sunlight insensitive and non-hygroscopic filament type. As PETG isnt suitable which kind of filament would you do recommend for someone who has to deal with extremely high temperatures as well as extreme humidty?

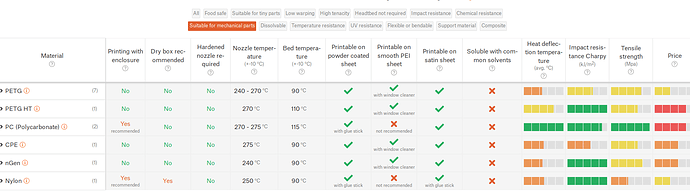

Selecting “Fit for mechanical parts” in the “Prusa” Material table results in this:

Polycarbonate and Carbon Fiber enhanced Filament most probably “fits the bill” (?) but both are (insanely) expensive so i rather would like to have a less costly option.

Then, any experiences with using bigger nozzle diameters? I am using a 0.6 nozzle atm and i am pretty happy with the reduced printing time and the (supposedly) 20% increase in strength. I am even considering buying a 0.8 or 1mm nozzle for the Lowrider-Print. Opinions?

Regarding my friend and his surf-hooks: The hooks lasted for like 6 month but now he gets more and more reports of snapped “surf-hooks”. So the PLA must be degrading. Most modern surfboards (shortboards) are very light. Maybe around 3 1/2 KG. We came to the conclusion that ASA seems to be a good choice of filament as Polycarbonate is way too expensive.

i would give HIPS a try, its very similar to ABS except its not hydroscopic and is much more rigid. in addition it is very cheap (about the same price on amazon as PLA) only downside i see is that it is not availible in very many colors (i hope you like black white and gray, though i think i found some blue the other day).

not sure what kind of temps you will be running the unit in, if its under 110, then you could also use PLA then coat it with a protective agent. i like using spray polyurethane. it comes in rattle cans (like spray paint) they have versions that offer UV protection, and it is designed to seal out moisture.

i don’t have a lot of experience with really big nozzles (like 1mm) but i do find that a .6 or .8mm are great for large prints, for smaller finder details (like the belt tensioners) i would probably not go much bigger then .6

there is another option, i don’t know how big & thick the hooks are, but PLA is known to warp under consistent strain. think of it kind of like glass, its strong but brittle and it will move slowly over time. so if the hooks are breaking now, during the off season. it could be that the strain from having the surfboards on them constantly is warping the PLA and causing failures. generally i would not recommend PLA for any continuous pulling load (you will notice when you build the MPCNC that none of the parts are under a pulling load. Ryan did an amazing job designing these parts). ASA is a great choice!

ColorFabb XT-CF20 Carbonfiber-PETG has double the stiffness of PLA, the temperature-resistance of PETG, is easy to print but unfortunately double the price but I like it.

Yeah looks great except the $55 for .75kg part XD

I think you would need at least 3 rolls to print an mpcnc… thats a pricey print

I wonder how its density compares with other filaments? If with the CF it’s a bit less than other materials you might at least get some extra length per weight vs. other materials.

We could hope, no details on density on the website.

Yeah, it just made me think of seeing a mast brace for a small racing sailboat on display once and almost throwing it over my shoulder when I picked it up. Incredibly light and didn’t feel like I could deflect it at all.

I couldn’t find Color-Fabb specific but I find generic PLA’s specific gravity to be 1.24 so somewhat surprisingly lower than the CF filled filament. So much for that theory.

I use it for 3d-printer parts. Its in deed not that lightweight but extremely stiff. And easy to handle without drying and printing in a housing - there is a Filament-profile in Prusaslicer.

Yeah, CF is awesome material, I’ve seen some motorcycle wheels made from it, incredibly light! Must be fairly difficult to produce as I don’t think the price has cone down all that much as often happens when a material becomes more popular and commonly used.

Sounds like you would need more than 3 rolls for a mpcnc. I would love for someone to try it though.