I like the way you roll. ![]()

Great Stuff!!

If you have the tools (table saw preferably) I’d mill the flat section with that to save a metric bucketload of milling and timber, then either glue the sections together (my preferred) or fix them in place separately.

The splayed cuts should help visually with any small misalignments.

If you don’t have access to other machinery - just keep going as you were! ![]()

Good suggestions, @bitingmidge! I do like the idea of saving the CNC some work (time) on the one hand. On the other hand, pressing the “GO” button and letting a machine do all the work sounds pretty attractive, too! ![]()

FWIW, I do have a table saw, bandsaw, jointer, etc. and have built some pretty involved projects, but this is my first venture into automated machining. I’ve watched enough YouTube videos from Cutting it Close and IDC Woodcraft that I’ve discovered the “true” roughing bits and I just bought a similar one from Amazon last week. Amazon.com

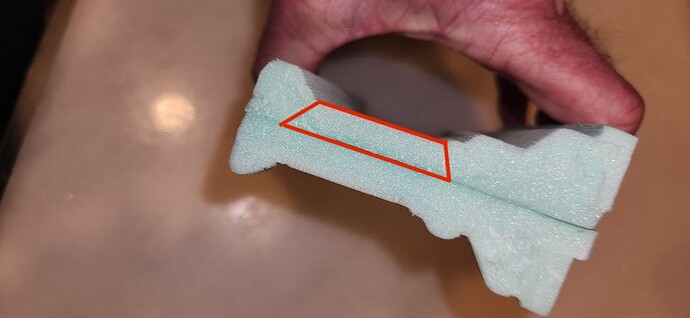

These bits chew through a lot of stock fast, and the serrated teeth help them do it. Granted, I’ve only tried mine in foam, but we’ll see soon how it does in wood.

My real underlying purpose here was as a POC to see if I could do moldings at all, and if so, my primary target would be the curved window tops in my house. For those, it would be really tough to create segmented stock as you suggest, even if the cuts were vertical (unless they’re cut by CNC?).

I don’t mean to disparage your comments at all – they’re much appreciated, and very much in line with how commercial molding shops make their product. For my special application, in limited runs, I think the added CNC machine time could be the better tradeoff, though. If I were making any significant amount of straight stock, absolutely – there are better ways than CNC to create this deep channel. If wood wastage isn’t an issue (or if you want consistency in the grain for a stained piece), then even a thick dado stack would give you a headstart on the CNC operation for adding the details.

Bottom line – I’ve just gained a new hammer, so every problem is currently looking like a nail. ![]()

Heh, absolutely know that feeling. ![]()