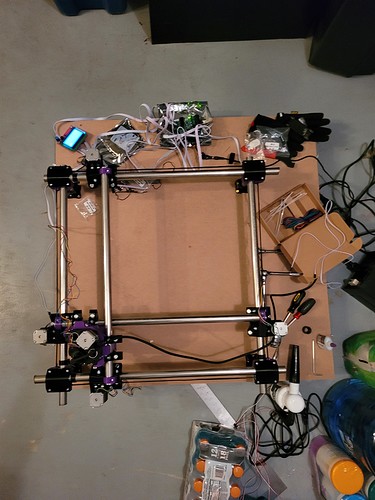

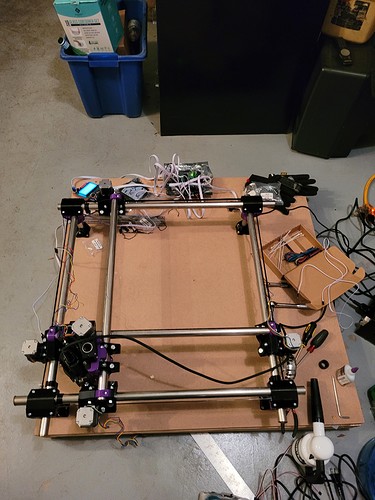

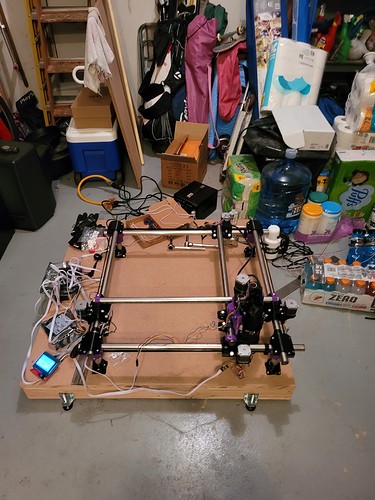

395 dollar spindle in a MPCNC for 600???

working machine for sale:

PA, United States

17"x17"x4.5" work area on 40"x40" floor level table

PRIMO Amb 1050 FME-P (ER16) for sale, stainless steel pipe, steel core belts, rambo 1.4 duel endstop Marlin installed and running (endstops in bag)

Comes with imperial and metric collets and printed With 75% infill.

10mm deep cut in 12.4mm deep 6061

Can post cutting video / chips.

Only let 1 image

Sorry for single photo posts. I’m a long time viewer of the forum without a id and a new user.

Bonus details:

Marlin firmware with duel endstops flashed

1" SS tubing from mcmaster carr

Steel core belts for extra rigidity

Prints, Fasteners and steppers all from V1 itself

Oh ans spindle takes 230v but I got a step up transformer so it runs on 115v like every other American appliance

Search the forums, steel core belts are far more likely to cause problems than to solve them. The problem is that they get flexed too far and the steel fibers break, causing them to go noodly and cause trouble.

Very highly recommended to replace them with fiber reinforced belts asap.

3 Likes

They last about 8 months of light use. Agreed they aren’t a permanent solution.

I’m selling this anyway.

jeffeb3

July 10, 2021, 11:00pm

15

We have done troubleshooting where they last about 8mins. The fiberglass ones work great. But YMMV.

Absolutely true. I think my main problem was that the kit came with just 3 inches too short for the belts.

I’m just repeating what I learned from NYC CNC shapeoko feeds and speeds video mentioning steel belts.

1 Like