As of now… I think I pretty strongly advise against plastic.

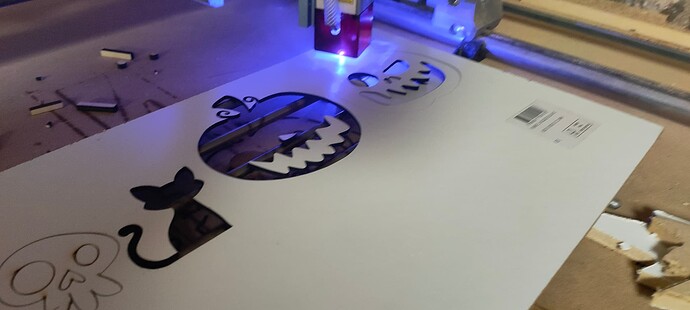

This evening I was dialling in my 5W CoreXY laser on some balsa… Ran the material test generated by LightBurn on the end.

I was right there but of course with the laser goggles on. Some flickering light is normal when cutting through, so… NBD, right? Smoke smell when working with wood also normal. Then the flames UNDER the balsa were OVER the balsa. Yank the power from the laser (Oh good! The printed plastic is also on fire!) And burning plastic diffuser is splashing onto other bits. Difficult to smother under the laser mechanism…

About 10 seconds after I saw flame, the frame of the laser engraver is on fire, the core of the machine has fallen onto the tray, and is on fire, the shelf under the machine is on fire.

I got everything put out. The machine of course is totalled. I am not even sure which lump of melted stuff is the laser module (probably the big one, but there are 3, each side piece and the core are all lumps of melted goo, and I don’t know which is which, about the only identifiable bits are the shells of the LM beatings.

This took seconds.

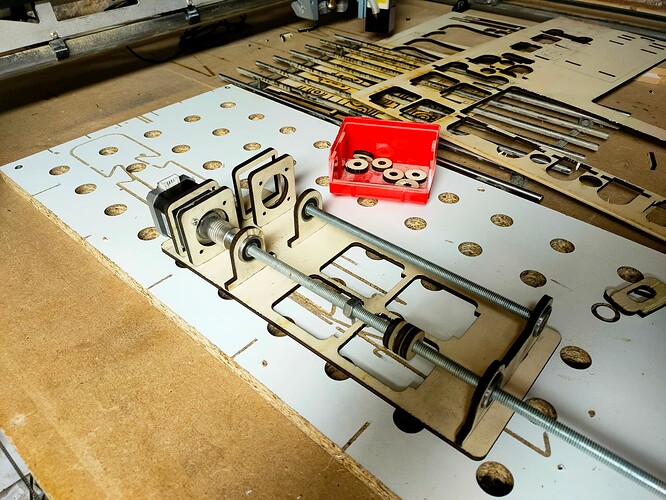

Not gonna scrimp when I rebuild, steel tray, snd proper waffle bed.

So my 5W laser module, the coreXY laser machine, one Ikea shelf unit, a sheet of balsa, and 2 spools of filament that were on the shelf beside the machine are definitely casualties. My desktop arcade machine was on the shelf above and now features a smoke finish, but I think it’s OK. An air mattress (deflated) that was beside the shelf unit might no longer be serviceable, and I got a small second-degree burn on my left index finger.

All in all, got off pretty light for a fire, but like I said… plastic light diffuser grilles are something I will never endorse, now.