I am in the middle of doing an Acrylic milling job on the LR2, and although I have “okaj” results I hope someone might help me to raise the bar to get a perfect result.

I´ve read plenty on the subject, so I started by buying Cast Acrylic 6mm thick.

Next I´ve bought 2 new bits, made in Germany, for the job;

- 3 mm thick, single flute milling bit

- 45° spiral chamfering / engraving bit

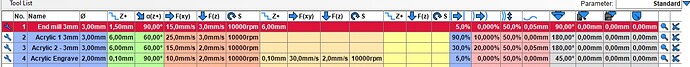

I configured the follow in Estlcam:

So as one can see I went the “Trochoidal” route to cut the full depth at once, and use the “Conventional Milling” direction. I am not using a finishing pass.

My Katsu/Makita clone is been set on number 2 for the speed setting.

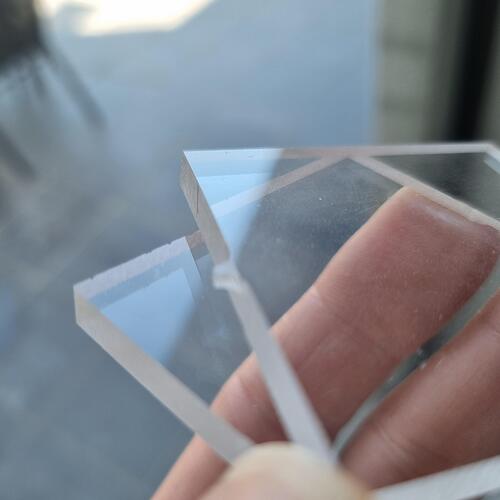

Using Tool 2 and 3 I do get the following results;

To clarify #1 is tool 2, and #2 is tool 3.

For any one interested; job number 1 ran for 6m42s, and job number 2 ran for 4m25s.

As I need a clean edge, clearly number 2 gives a better result by using some “Trochoidal oscillation”. However it is not a “see through” edge as I needed.

So tried to do some flamepolish using a torch. That gave a little more polished edge, but the sharp edge got lost doing so. So that´s not an option.

=> does anyone have an idea on how to achieve a clean see trough edge?

I found some bits from crown-norge that have impressive results, but those are -to my understanding- for high speed CNC´s.

I also noticed that sometimes the edges are a bit damaged. And I can not seem to figure out why this happens as it seems random, even with a new bit in use…

Have a look on this image, left piece, top side:

As I need to put some text on it, I started to experiment engraving with the 45° spiral chamfering / engraving bit, using tool settings 4. Doing a 0.2mm engraving I get the following result. You will notice that the Acrylic seems to melt and stick to the surface.

I manage to get rid of it by running the job twice, however due to the hardness of the acrylic, the two jobs don´t match 100% making the text a bit shifted.

Am I using a “wrong” bit for the engraving? Might be, as it´s my first time doing so and selecting a bit was… difficult with all the options available

Next,

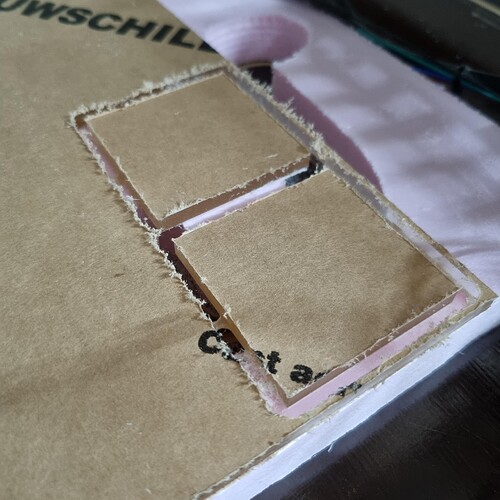

I need to mill like 40 pieces of rectangles. Obviously it would be a pain in the but to set up each job. I figured out that the current setting for a 3mm bit, using 50% stepover, creates a tool path of 4.5mm. So was thinking to make 1 design file, and space them 4,5mm in between. But how would one then avoid Estlcam to cut twice, even if one side is already been cut?

This would save me a lot of time, and machining time.

And my final question, I had to make cut too with an “internal” corner of 90°. Found out the hard way that this was not going to work, as a bit is round so you always have some radius. Didn´t think that one through as I am used to let it be made using a laser cutter…

How do you guys work around this?

I was thinking on ordering a 1mm bit so I can minimize the radius, but then I can´t find a bit that has a 5mm cutting edge length