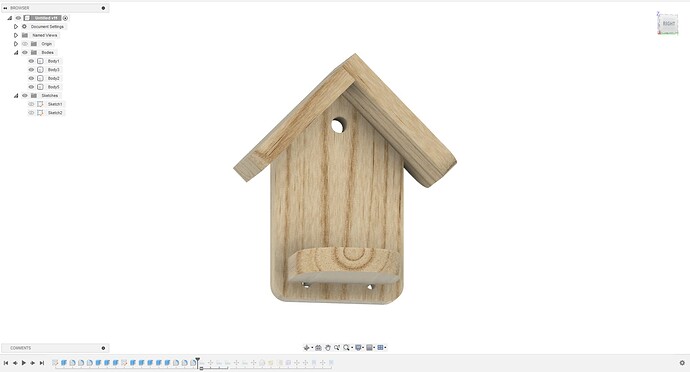

Nothing too fancy, quick simple project with just a bit of fancy carving on the roof ![]()

Perfect alibi for trying my new 6mm ball bits ![]()

I really envy your Fusion skills. I wish I was like, 0.1 times as good. I am better at 2D drawing and 2.5D thinking. 3D modelling is hard. ![]()

Love the roof panels!

I would say that is an 8/10 fancy, nothing simple about it. You have joinery and carving in the same project.

Same. Although I can very easily think of 3d designs but my software skills are near a zero right now

The initial plan was to include some dovetails for the roof top, but I’m not quite ready for this just yet ![]()

With this, it would definitely reach an 8 or 9 though! ![]()

Making a second/bigger one right now…

I changed the CAM to have faster and deeper cuts… sweet sweet shavings ![]()

![]()

![]()

I also changed the CAM for the roof tiles, taking a first 3D parrallel pass with 3mm DOC and 3mm wide stepover, and then a second faster parrallel operation with a fine 0.3mm stepover

It’s 3x faster, and a lot easier on the bit

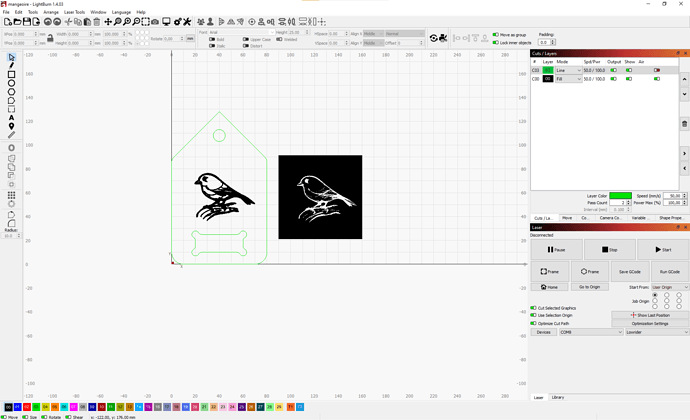

i might try to add a laser-cut inlay if I’m filling brave, just to get that extra fancy-point ![]()

Apparently, my previous feeders were a bit too small , so… XL version time…

Parts layed out flat with the great mapboards pro plugin

My wife has been making ceramic tiles she wants to put on the roof, but we need a handful more of these

Can you tell me what bit you used for this please? I’ve been struggling to get such a good finish on similar dished design.

Just regular 6mm ball end mills

You need to be very mindful of the toolpath though, as you need to make a 3D carve and have a good finish

As stated in the second one I made, for the tiles, I made a first pass with 3D adaptative cleaning and rough 1mm step-down and .3-.5mm stock to leave, both axial and radial, and then a second pass with a “3D parrallel” operation, 90° from the previous direction, for the finish

For the dish it’s just a 3d adaptative clearing, 3mm rough stepdown, .3mm fine stepdown, no finishing pass