Hi All,

I want to use this thread to share my progress on my Lowrider3 Build and for any potential troubleshooting topics that may need solving in the near future.

Info: Updated pictures and videos after getting user status updated from New User

But first, How did I get here?

My Ender 3v2 has been sitting idle for some time and I wanted to attempt a DIY CNC build for years but never had the space, time and means to do so. Fast forward to July 2023 – me going down the youtube rabbit hole of DIY CNC and trying to figure out which build I would pick - I stumble on Doug Joseph’s and How-to-Homemade‘s videos on the LR3 on Youtube and the plan starts to form in my head to finally go ahead with a lowrider vs other alternatives.

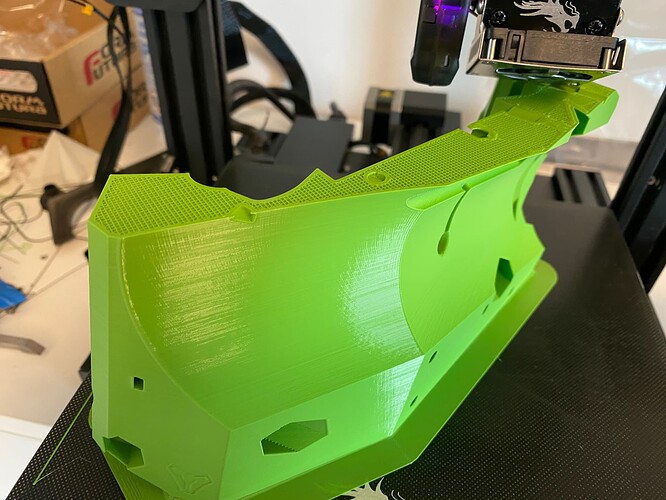

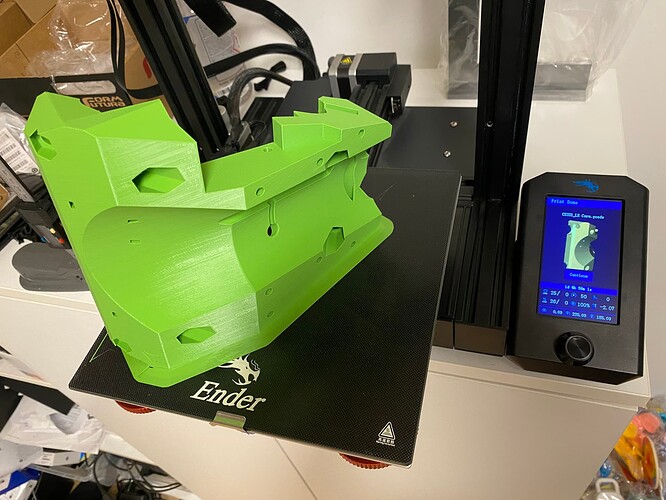

Not sure if my printer would manage it I start printing the core on 04. August with 0.2mm layer height and a print time of 32 hours. After a night with very light sleep and some more anxious hours I come back to a finished print – that even looks decent in my eye. This is the point where I decide to commit to this.

Some questions that still went through my head:

- Do I have any projects where I need a CNC? – No

- Do I really need a CNC? – No

- Is it wise to spend so much money without need? No

- Is it potentially a great tool to have? Can I learn something on the way? Do I want to learn about CNC machining? Is it ok if I fail? Will my wife and friends maybe call me crazy? –I guess Yes to all of those.

Ordering from Ryan is not really an option from Germany due to Shipping and Import taxes so I ordered all parts individually from Aliexpress, Amazon and other Local stores and sent my printer on overtime duty.

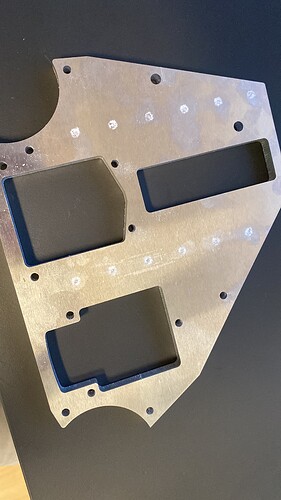

I got the 25mm Rails in Stainless Steel with 3mm wall thickness and decided to order both the yz and xz plates from an on-demand laser cutting shop in 10mm and 6mm Aluminum as I had no other way to get milled parts and well… If I already custom order them I can get them made out of Metal and after 20 working days they finally arrived.

One Problem: I did not think through how I would attach the Linear rails to the Aluminum – Wood Screws wont work… At least the laser already marked the spot to drill from the provided DXF.

Well let’s order a set of Taps, graduate the „How to tap Holes“-YoutubeAcademy™ and manually tap 24 M3 Holes– New skill unlocked. It worked! On to further assembly.

This week I was able to make the most progress thanks to some days off. A challenging part was the wiring as I never crimped a Dupont Connector before in my life that i needed for the wire extenders I had to make myself.

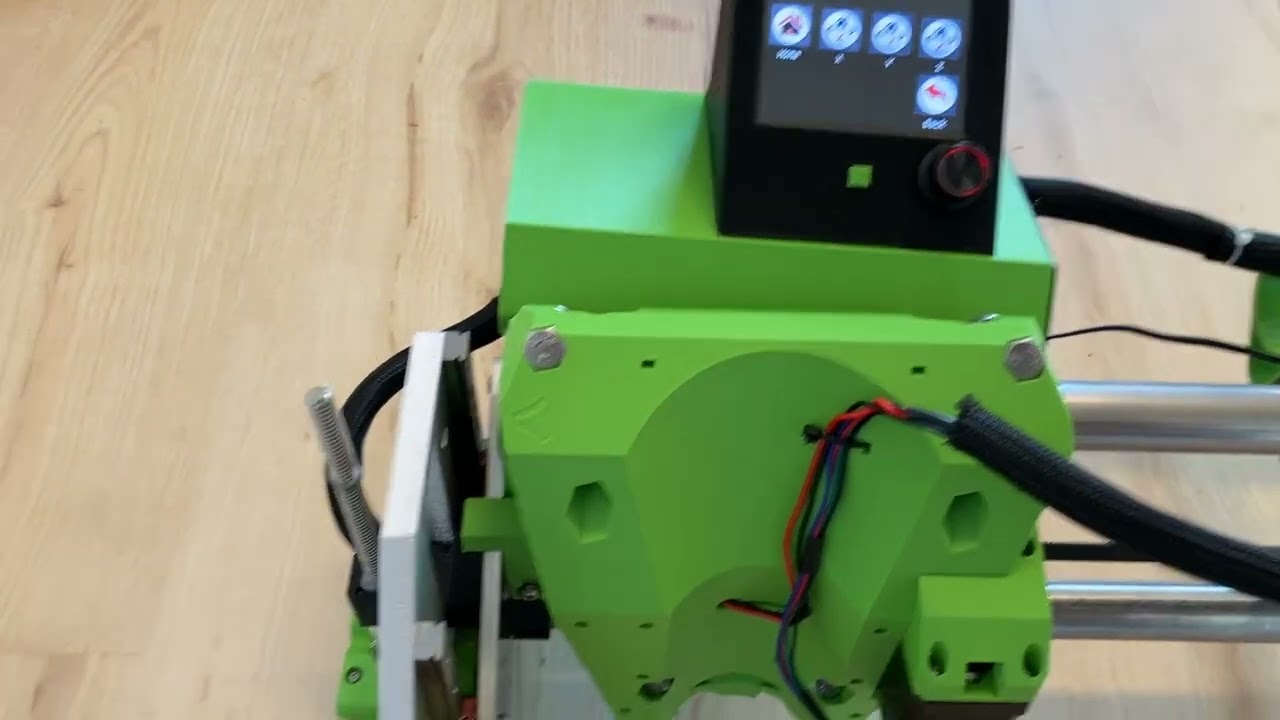

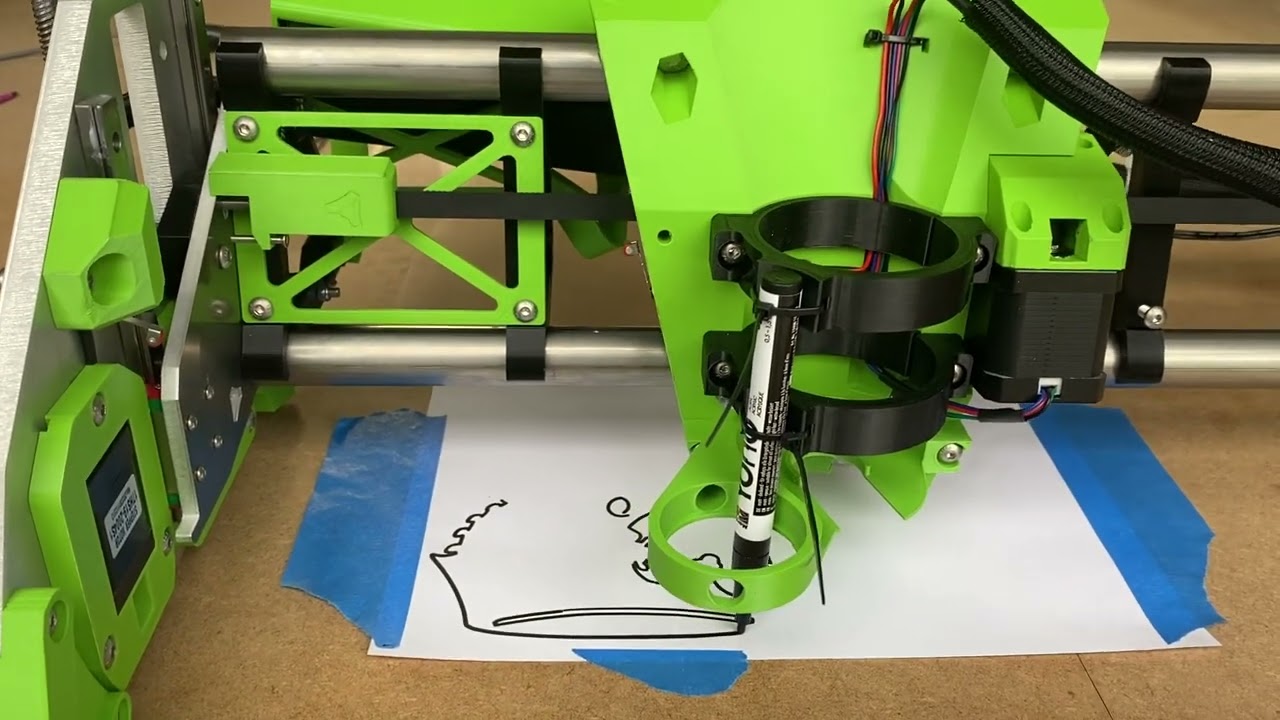

Testing the connections and X-Axis:

And today: IT LIVES on X&Z

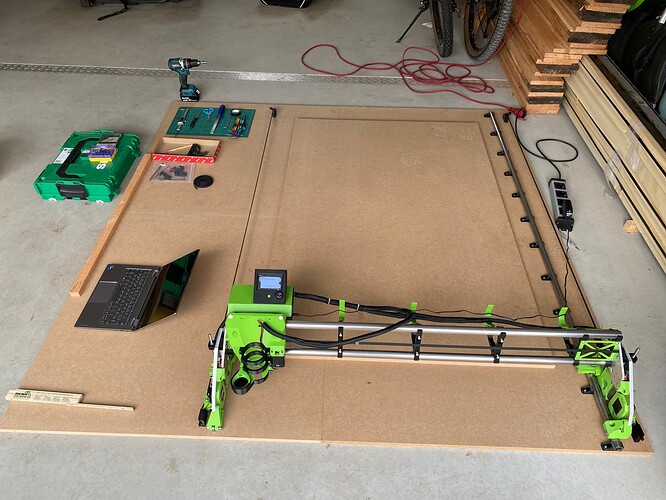

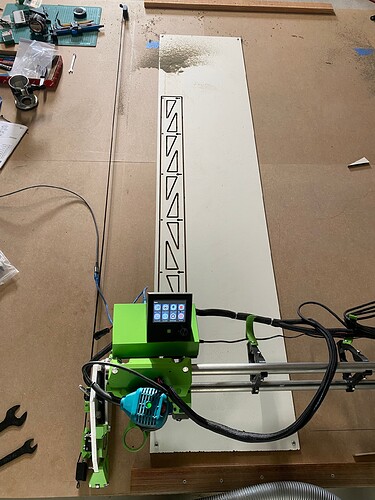

In its final form it will have roughly a cutting capacity of 1000x1600mm due to practical reasons as I can not transport material wider than roughly 1 meter with my car. I intend to build the torsion box shared by Doug that I have already modified to my dimensions after learning the basics in Fusion 360.

Two issues I have currently:

- The Z-Axis is lightly Squealing only when driving down. I have seen another post already with someone having the same issue but The fix to add Lube did not really help. I think it is the flexible couplers that produce the noise. The noise is only present under the load of the main beam.

- The TFT35 display returns unkown command M420 after homing but I think its solved by a firmware update from BTT if I remember reading correctly on the forum.

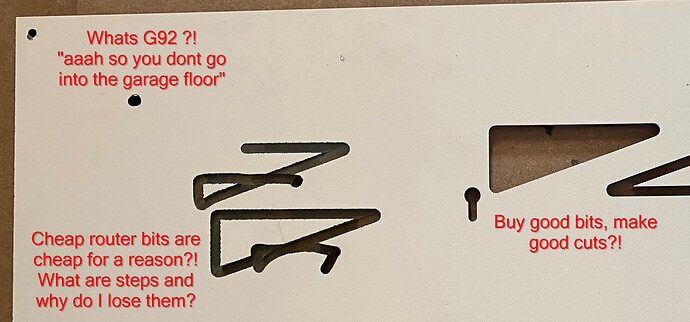

Today I picked up some 19mm MDF sheets from my local supplier and will try to get the first test cuts done on the weekend if I can manage time wise.

Until Here I can only thank Ryan and the Community that got me to the current state of progress through sharing knowledge here and on youtube. I learned a ton of stuff so far and really enjoy where its going.

I will try to keep the post updated with progress and issues if any occur but expect slow updates.