I pulled the trigger on one of these (“JL1”) laser engravers last week and it showed up Saturday.

I figured I’d relay my experience:

6 screws to install the X rail & cable chain and it powered up. It homed against the limit switches and then traveled to the opposite corner and turned on the “+” alignment indicator. Movement is nice and smooth and overall really impressive at this price point.

I didn’t even bother polluting my computer with the included software; I used the GRBL update package David provided and it flashed fine (and rather quickly). Hurray; GRBL 1.1f! Thanks David!!!

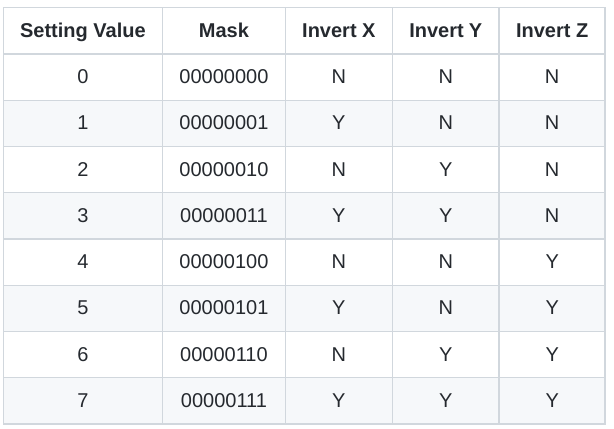

Using UGS I fumbled around a little with the configuration parameters and determined that $3=2 gives the most sane results for me as well (Curtis shared $3=3, along with a couple other subtle changes from the defaults). It appears to work perfectly well besides homing.

I did beat my head on the wall for a while trying to get homing to work via $23 homing mask and machine size soft limits before I went and read the original Lightburn Forum Posts. It turns out the upgrade tool in upgrade.zip (post 14) is a pre-compiled binary for a “JL3” engraver that has the same controller but different X polarity and limit switch configuration (ie the need to change the $3 parameter from it’s default) but also has a different (slightly larger) working area. The JL3 firmware also has a hard coded G92 offset that is applied after homing and a auxiliary travel command to park at “0,0” immediately following the homing sequence. Consequently it tries to reach 90mm beyond the Y-travel limit and crashes into the rails. Enabling soft limits doesn’t help because as soon as the G92 offset is applied the machine thinks it is out of range and throws an alarm.

So, “Homing not supported” is clearly indicated in both the Lightburn posts and mentioned by David, and I can provide independent confirmation  . The other limitation of the “upgrade” software is that turning the alignment laser cross-hatch on and off is not supported. This also mentioned by David and others but is a complete non-concern for me - it has an odd x & y offset from the cutting spot anyway and could be manually switched if desired.

. The other limitation of the “upgrade” software is that turning the alignment laser cross-hatch on and off is not supported. This also mentioned by David and others but is a complete non-concern for me - it has an odd x & y offset from the cutting spot anyway and could be manually switched if desired.

However, I think there is a way to get homing to work via a set of macro commands. I am going to try to temporarily change the step/mm configuration (lower) before homing and then reset it afterwards. It will be confused about where it is relative to the limit switch, but following up with a new G92 offset should correct that.

Also, for awareness; on the Lightburn forum, there has been some recent discussion about compiling GRBL from source code and what the appropriate pin configurations are. Sal has what he purports as a much better version of firmware that supports both homing and triggering the alignment laser via M commands. While neither homing nor the alignment laser is really necessary, I am considering giving it a try for the fun of it. The only challenge appears to be that the JL3 GRBL upgrade firmware eliminates the bootloader that was originally supplied on the control board, so it needs to be programmed through something like an STLink. In addition to getting one of those $10 device, connecting it requires soldering on some pin headers and learning the uplink software so is far more effort and carries some level of risk (If I brick it, I’ll just have to get a more GRBL friendly controller  )

)

I am not certain, but I think you could probably flash the custom JL1 specific firmware .bin file directly to the board with the update.exe tool if you do it prior to wiping the bootloader though I think you still only get one crack at it before you have to resort to an STM programming interface tool. We’ll see if someone wants to be a guinea pig for that - its too late for me.