I know there are many available out there and I have downloaded one from thingverse. However, on a whim and to do a couple of projects for my kids, I purchased a XTool D1 laser set up. I have had nice success with it so far. I also purchased their RA2 roller/chuck attachment. Which has also been successful on several projects. My question is, is it possible, and how would I go about using the attachment on my MPCNC? It is much sturdier than the one I made from thingverse.

I know a lot of you all are very smart and understand advanced concepts of cnc world, but I am not. I rely on your knowledge and experience, for which I am most grateful.

Thank you for your help on this as well as the many other questions I have had.

I just ordered a 4th axis roller from Amazon - should be here tomorrow. I’m sure there are folks here who have already done it who can give you more detailed info, but here’s what I expect to need to do: 1) Disconnect the two Y motors on the MPCNC. 2) connect one of the Y outputs to roller connector. 3) Do some tests to determine direction and steps/mm. 4) Profit!

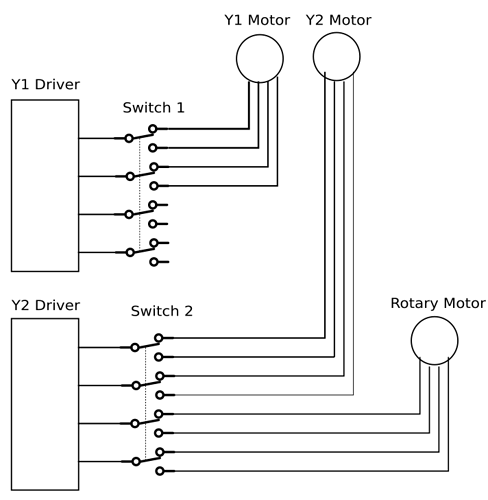

I also bought a couple of 4 pole switches - I plan to wire them so I can switch between the MPCNC Y axis and the roller with just the switches, no disconnecting/reconnecting needed.

Add a step 0.5 - Power down the controller before plugging/unplugging stepper motors.

Oh man that’s a good point. I need to put my switches somewhere where I will need to think about the power status before flipping them.

Sounds like you’ve put a lot of thought into making this easy! Please post your attachment and switches once you know how they work out. I just received my Ortur laser and am interested in laser engraving water bottles as gifts.

What kind of machine do you have? Brad was asking about using the RA2 roller with the MPCNC, which is what I’m going to be setting up with a similar accessory meant for a standalone laser machine. Do you also have an MPCNC?

Yes - pretty new, and I’m sure rotary is completely over my head, but I can dream!

I don’t have much Z-height. I heeded the warnings to keep it short, but I might be able to drop the table if needed to accommodate the attachment. Just wondered which one you were working with. I was also thinking Aviation connectors for the Y axis ballet, but your switch sounded interesting.

I’m also very new to Marlin (my printers have been RRF) but I’m staring at a poor unused driver slot on the SKR Pro and thinking how that might be part of the solution.

Interesting - hadn’t thought about using that last driver. I think you definitely could, but you would still need to disconnect the Y1 and Y2 motors and connect the rotary to switch over - I think. One of the big brains might know if there’s a way to switch between driver configs without having to disconnect.

For my idea, here’s a rough sketch of what I’m thinking.

I just got the switches today, and the rotary comes tomorrow. Who knows, maybe I’ll stop trying to burn down my house long enough to get it wired up!