By all means, ask away! Glad to see someone else considering it. I was a bit mixed about getting it based on the commentary I’d seen online but the price vs features were too good to pass up.

It has been excellent. Zero first layer issues, zero adhesion issues. I’ve only put a kg of PLA and a kg of PETG through it so far and it has been perfect. Probably the most demanding print I’ve done so far is the Flexi Factory print-in-place flexible T-Rex, which came out amazing.

Everything articulates like it should, the snap-together pieces are firm and rotate easily with enough friction to stay in place. Next plan is to build a maximum sized version for a friend in either black or rainbow PLA.

The only odd thing was that the default PETG profile used the cooling fan which resulted in brittle prints with the eSUN PETG that I’m using so I had to turn that off. I saw the comments about rooting it and so on but I decided to just use it for a while first and it has been fine. There’s nothing yet that I’ve found that I’d need to root anything for.

My bed was tilted very slightly (~1mm front to back, not terrible over 300mm) but the mesh leveling dealt with that with no issue. I decided I wanted to try improve it slightly so there’s a Creality standard bed leveling process I followed. It’s basically loosening the Z drive belt, screwing the bed down with the shipping screws, re-tensioning the belt and re-doing the bed mesh leveling. Mine didn’t really change much after doing that so I printed some shims that go between the Z ‘trucks’ and the bed frame attachments. I think I used a 0.6mm in one corner and a 0.2mm under the back and that brought the whole thing to within 0.5mm at all points on the bed, which I’m plenty happy with.

Bed leveling process:

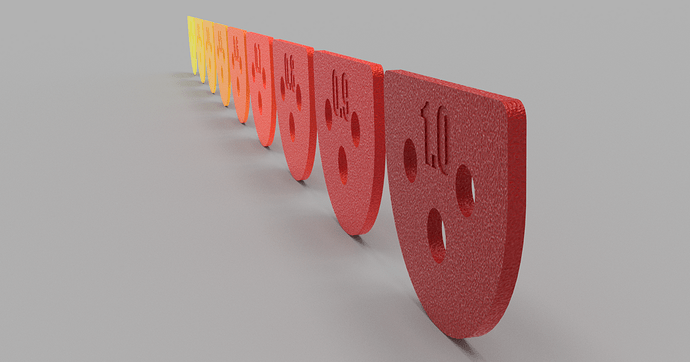

Bed shims:

I’ve also looked at all the complaints about the door swinging open and breaking as well as the printed parts to fix it. I planned to do that fix but after using it for a week I realized that short of me tipping it over on its side there’s zero chance I break the door like that.

The Creality slicer is a bit different to use in a few ways but nothing that has caused any actual issues and it has enough nice stuff like being able to one-click print and monitor the printer remotely that I’ll keep using it.

The web interface for the printer works really well and is nicely responsive…

I also got one of the Creality Space Pi filament dryers at the same time. It works fine and seems to match up with K1 Max’s filament path reasonably well. The touch-screen is hot garbage but that’s fine, it’s not super critical. I printed a little tab that holds the lid open when it’s in drying mode to allow air to circulate. I also tucked a couple of packs of silica gel from filament packs into some unused space in the bottom of the dryer. For a full reel of PETG I propped the lid open with the printed tab and ran it on the PETG setting for 4 hours. I then let it cool down, pulled the tab out and shut the lid. Since then it has been maybe a month at 60-80% humidity and whenever I turn on the filament dryer to check the internal humidity it’s around 15-20%… It works surprisingly well just like that. I haven’t needed to re-dry the filament since then and it has been printed perfectly.

That’s everything I can think of. Hopefully that helps! Absolutely feel free to ask if you have any other questions etc. or want me to take photos of anything specific, check dimensions etc.