Hi,

I want to present you my current 3D-Job. It is not finished yet but I have realized a couple of steps so I think I can show the first steps and I will give you some updates in the next couple of days or week … if you like ![]()

My current project is an “Excalibur Crossbow Stock”.

Excalibur is a canadian crossbow manufacturer who is constructing really fantastic crossbows.

My crossbow is a “Excalibur 365 Micro black limited edition” (for the specialists: with ArcheropterX Hunter 9 Scope, R.E.D.S suppressors and a couple of other accessories)

So here is the original:

Although I like the “clean” and black stock, I would like to change a litte bit the design of the crossbow.

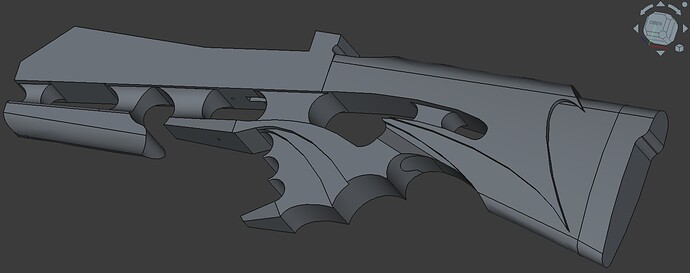

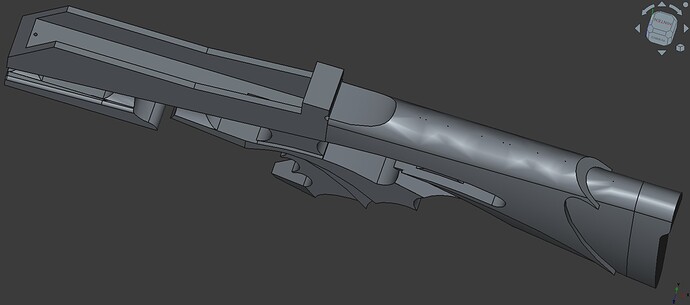

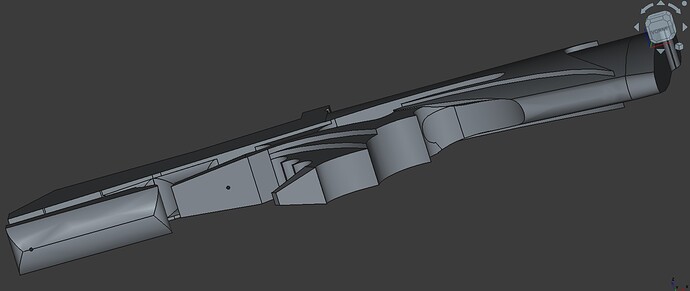

So I have started to “draw” and experimenting a little bit in FreeCAD.

This was the result.To be honest it was quite a hard challenge to “draw” it in FreeCAD, but the result is …. let’s say …. presentable ![]()

![]()

![]()

![]()

To not waste the “expensive” wood, I created 3 or 4 prototype out of polystyrene, to get exactly the right dimensions and that the body of the crossbow will fit correctly in the stock!

I have modified the back (at the shoulder) so that this stock became 2.5 cm (1 inch) longer.

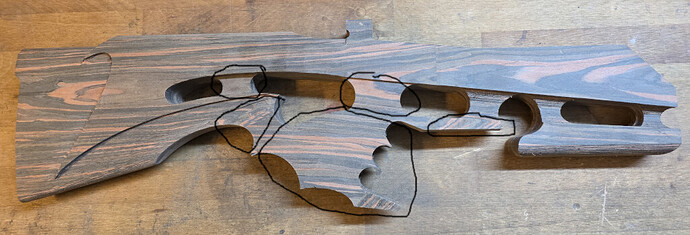

This was the last “prototype” I have realized.

You can see that left and right sides are different from each other. The stock will be for right-hander use.

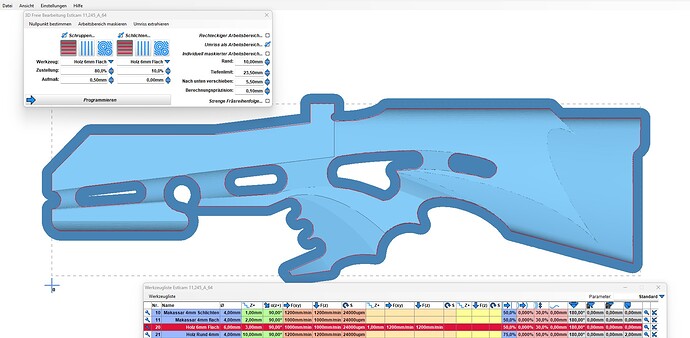

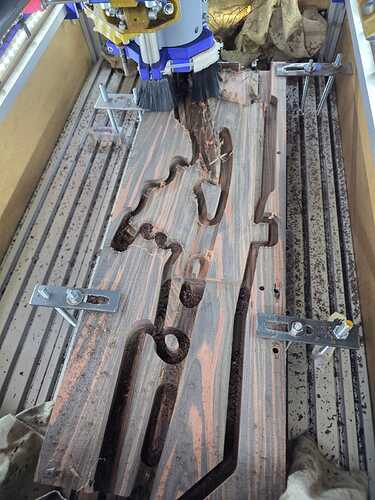

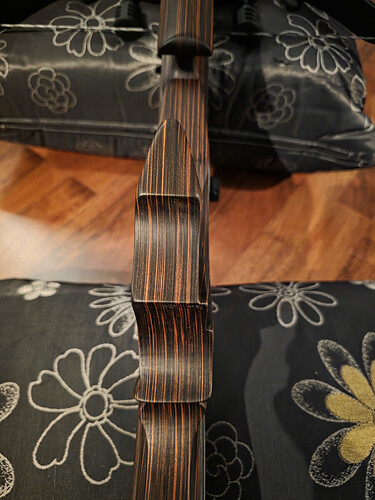

After the last prototype I started with the wood.

Material: Makassar Ebony

Dimensions: 620 x 220 x 60 mm

Drill: 6mm flat

Milling duration: ca. 12 - 13 hours (even with a speed of 1.000 - 1200 mm/min) but I wanted to get sure, that the surface would be quite fine.

I had to run the milling in 4 steps, 2 for each side because the length of my milling bed is only usable for 50 cm.

So now I got:

Original, first design on paper, last prototype and the 1st step of the wodden stock.

It is really COOL! ![]()

![]() and I am existed, for the next steps:

and I am existed, for the next steps:

- Slot for the crossbow body

- grind/burnish with (180/300/400/600/800/1000) paper

- oil / wax the wood

So - of course - still something to do but the base is … (in my opinion) fantastic ![]()

![]()

![]()

… to be continued ![]()