No, i can show /guide you on how to create the 3d panel flattening and cutting file. This is because each panel will be different for every use case (you have to measure the wall, and place an equal/distributed amount of panels to fill it with no gaps) in the end its pretty easy

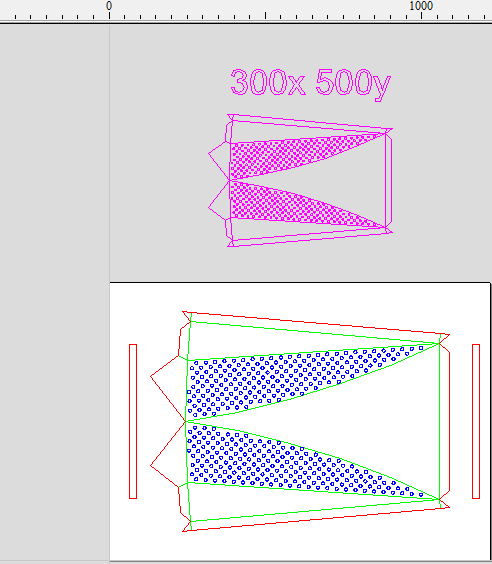

Just let me know you will need SketchUp as 3d cad software, a software called Ultimate Papercraft to make the panels flat (or have the knowledge of doing it inside SketchUp using 2 extension -flattery and uv to get the flattened part) and any cam software to make the route (vbit) &cutfiles (exterior)

Hello Cesar, how are you? I would like to ask you several questions about it, one of them is what software you use to send the order to the cutting machine (hear that Sharp 3D works well) among other questions that I would like to send them to you via email if you don’t have trouble

I design them in SketchUp, you can flatten them using some extensions but i use a papercraft software you could use any . Then for cutting and vroute i just use Vectric aspire. You can use estlcam

Since I use SketchUp quite a bit, I found and downloaded the extension called Flattery, and got it installed (but not yet tried).

Also, Fusion 360 (which has a free hobby user license) has flattening of folded shapes in its “sheet metal” tab of options.

hi sir

how we can get the design acp sheet 3d design

Cool work my friend! Do you know where I can get any files ready to cut?

What software are you using to unfold the 3d shapes, and is it important to add thickness while working in 3d?

hi

what feeds and speed did you use ?

im trying get setting’s right using a 0 flute acm bit

just cant get it right , getting little bit of bured edges and some jaggered bits

Hi, it depends on the acm brand we cut (some are better-aluminum faces more thicker) 1440mm/min up to 2000mm/min with 12500-14000 rpm spindle, single pass. Just follow the ipm and or the chipload for your bit

Is your material getting some air under while its cutting? What you described of the rough edges happens when the sheet gets lifted and it vibrates

hi yip my settings ae within your numbers

was wondering if it could of be lifting

might have use double sided tape in middle of sheets

This is a cut using my settings in a machine without a vac table:

Just a blast with compressed air. You need to make sure: plastic core is cutting chips, if not it gums up resolder and heat will kill your bit.

If you are using 4mm acm do a test with 2 passes one 3mm the other one 1.20mm extras and see if you get a clean cut that way

Do you see the sheet lifting and vibrating?

I love that! I would love to see the whole panel after it’s in place too if that’s possible.

Do you vee both sides or just fold in the opposite direction?

The curved bends will stay put, I know, but do the straight bends on the edges have any spring back?

Thanks.

Wow, curves break my brain.

This is really incredible. <3

I also dig the safety footwear. ![]()

That is just amazing!

Impressive work!

after you fix the panel it stays put. i have a small strip of acm installed on the inside attached with ca glue first then with screws