Has anyone built a lr3 large enough to work full 2 meter x 6 meter sheets of aluminum? I have built and run a 4’x8’ lr3. I wonder if the weight of the gantry would overload the steppers. Yes I know it would take forever to cut that size material.

Has anyone built a LowRider near that size??

yes…

Can it cut aluminum? I’m not so sure…

The linked beast of a machine was running a laser, not a router or spindle.

I don’t know that I would attempt to use it as a CNC machine at that size

How thick, what grade? What accuracy do you need? What on earth are you making ![]() ?

?

Largest I’ve seen is someone cutting 5’ x 10’ alu sheets for the seaplane kit they’re building My second lowrider

The 4x8 cut aluminum without a lot of problem. Was better with 10mm thick aluminum than with 6mm carbon fiber. 5083 alloy for ship building. Accuracy at 4x8 was down to .1mm so if within 1mm at a larger size would be acceptable. Building a 36’ sailboat. The hull sheeting would have fewer welded seams cutting full size sheets. The sheets vary fron 1/16" to 1/2" with 5/16" being used for hull and deck sheets.

The biggest concern would be the rigidity of the gantry at that size and the ability of the z axis steppers to support it’s weight.

Already using thick wall DOM pipe for your gantry?

2 start instead of stock 4 start lead screws will help with z torque, but halve the speed.

I have less advice than questions for your awesome project(s). Hoping experienced folks here will chime in whether nema-23 and/or other upgrades are right for your requirements/budget/time.

What time frame are you looking to build? Did you see the latest V1E video showing a more rigid LR4 Beta is in the works… No idea if/when it will be released.

Guessing I’m not alone in wanting to see how your project(s) progress. Cheers!

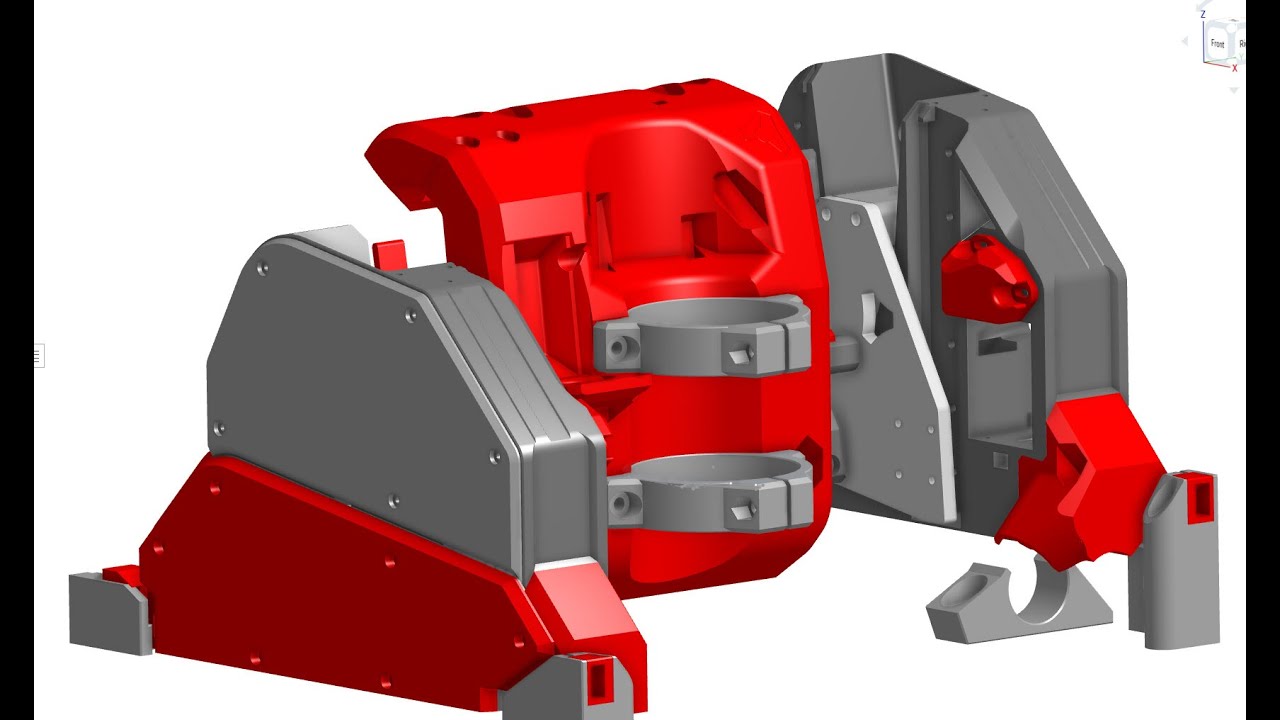

I have seen 1 lr4 video. Probably worth the wait. Won’t start cutting until winter. (Have to sell my current boat first) Changing stepper size is a huge problem with the design of the lowrider as it integrates them deep into the printed parts. That is where a lot of concern comes in. But $500k for a premade machine is out of reach.

You can use 1-start leadscrews for Z instead of 4-start, and you get 4x the lifting strength with no other changes. If you have at most a 2x increase in weight it should be a slam dunk.

Those NEMA17 motors will support a lot of weight even with 4 start screws. I did some weightlifting experiments with my LR3, and aside from the 4’+ gantry it would lift a good deal more without skipped steps.

I should see how much the LR4 will lift with 2 start screws… that reminds me that I still need to lube those…