Hello , to everyone from sunny Egypt,

For almost the last 2 years i have been hording parts for my MPCNC build , and the last of them is tubing and i have sourced stainless steel from a friends company and it was cut and polished to perfection, the current problem is in regards to the printend parts since my stainless steel (od 24 mm) so i dont know which in the 3 sizes of printed parts will be suitable, secondly after going through the build manual i have found the the z tubes need more id for the nut trap printed part so i had my friend to cut me 2 extra tubes for z but this time its 25 od and 19mm id , so what size of printed parts fits snuggle the 24mm tubing and should i print the core in 25mm size to accommodate the z tubes and the rest for the heavy duty 24 od tubes, sorry for the long post but im really lost ,

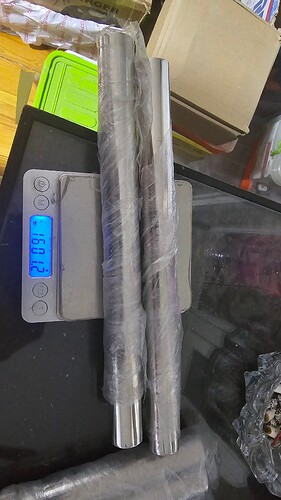

That is the 24 od , 10mm id tubing

The is the z tubes od 25 id 19

The ‘C’ variation is generally for USA/North America, where EMT Conduit is cheap and relatively ubiquitous, and is ~23.5mm OD.

The ‘F’ variation is for Foreign builds, where metric tubing is frequently available, and is for 25mm OD.

And the ‘J’ variation is for Jumbo applications, where 1" (25.4mm) OD is used.

I would say go with the 25mm version, as those slightly smaller tubes are going to be extremely heavy. If you look at the Primo Parts list, it will give the full breakdown (including suggested wall thicknesses).

edit: I didn’t fully read/comprehend your post the first time… You should probably get the other 6 rails recut with the 25mm, but thinner walled stock. Pushing 1.6kg+ of just gantry around (not to mention whatever spindle you add to it) is going to seriously stress your machine (and really slow it down due to acceleration issues).

And welcome to the madhouse! Things can get a little crazy around here (I know, I’m usually the one driving things off the rails), but everyone really wants everyone else to succeed and have fun, so don’t hesitate to ask questions and (more importantly) show us what you’re up to!

Thanks for your reply, and i have figured it out in regards to z so thats why i have those 2 tubes cut off 25mm od 19mm id (also for the nut trap print) and lower Wight (around 1.5kg) including a 52m spindle , but the rest of the 6 tubes i would have to figure out an appropriate 3d printed size to accommodate them since the stainless steel costed me little more than i can easily recut , so what size would work with the 24mm tubing , and also i think the Wight for the structural 6 tubes will help in the rigidity of the frame