I now mixed wood glue with a little water and “painted” it again. Will see if that works this afternoon I guess. I still have the option to pour a layer of epoxy if all else fails.

To close the different zones of with a something subbery, like a window seal, is a good idea for sure. If you’re planning on using them separately. Maybe even a must.

Also we used to put a round of painters tape around the spilboard when I worked on a big machine. Made a huge difference, partly because no air could sneak in through the side but mainly I think because no air could sneak in from under the edge.

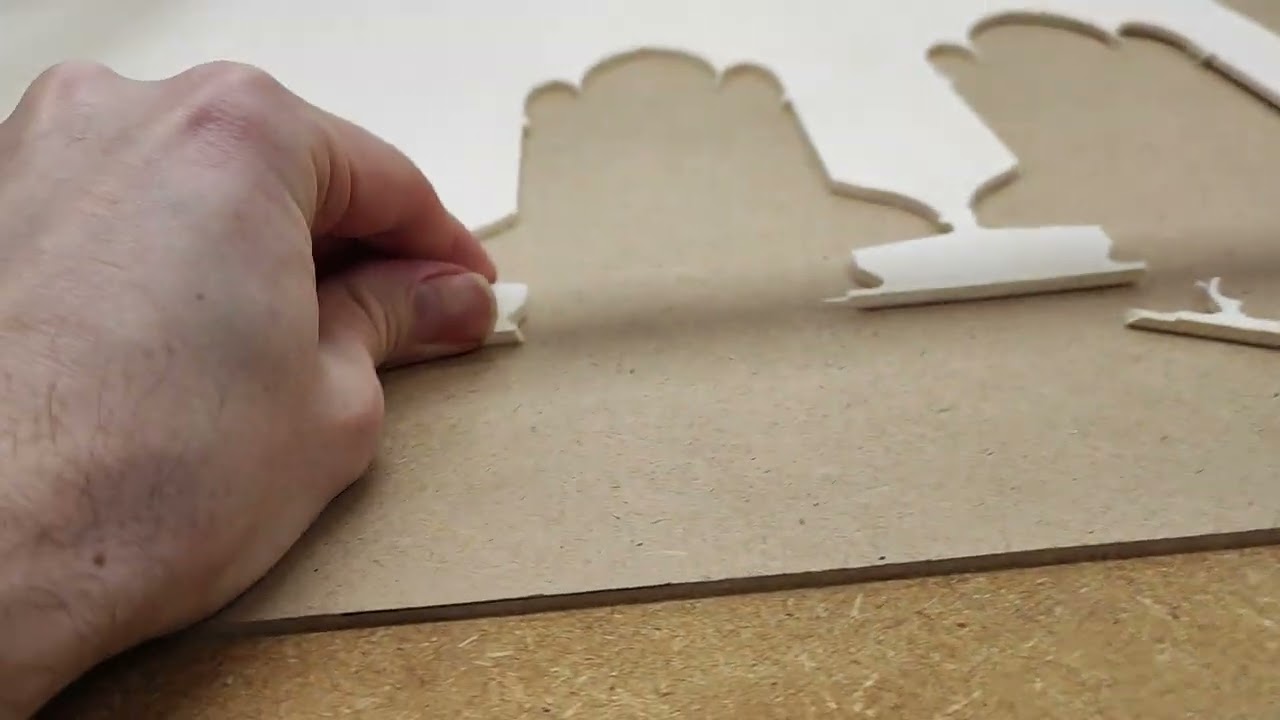

New spoilboard with Plywood sides to stop the air from escaping.

/edit: Not using this spoilboard at the moment since it is too thick.

The spoilboard is muuuuuuuuch too thick. I should have known that 18mm is waaaaaaaay too much (but hey, why think when you can just not. Ordered a 5mm board as well as some PE-insulation, will arrive in a week or so. Uff. Until then I have a fancy new spoilboard… Thinking of doing that thing with the pegs, you know? where you have holes and stuff and can put plastic in those holes. You know what I mean.

I know, I know: Again, another post? This thing is a rabbit hole. Grrml. Iff (if and only if) the treated MDF should still not be airtight and working with the 3mm plate (and another problem is that my whole cutting area is in a 15mm hole then (does not matter too much if I don’t get close to the borders), I might buy a PVC Plate: PVC Platte weiß 10mm, which definitely does not let any air pass. This guy makes tables with it and a 3mm plate and it seems to work well: Vakuumtisch nur 16mm hoch - CNCWerk-Forum. It’s German, but TLDR: 3mm Alu-Dibond, 10mm PVC, 3mm MDF. I could be doing the same but with my MDF baseplate I already have. But only if it does not work with the 3mm.  Will keep you posted.

Will keep you posted.

It woooooooorks! Without insulation yet. See the video, I’m pulling and pushing with all my strength.

![]() appreciate seeing your progress. What’s holding down the stock, I couldn’t figure out?

appreciate seeing your progress. What’s holding down the stock, I couldn’t figure out?

does that tell something about the holdingpower, or your strenght? ![]()

Air.  It’s an old vacuum cleaner.

It’s an old vacuum cleaner.

I am missing something. I am not quite following what the resulting final design is here. Do you have that painted with glue spoil board you were talking about sitting on top of that board with the square/channel/maze and holes in it? Do you then have mating holes in the spoil board so the suction can reach the work piece on top of the spoil board? In the previous picture of the spoil board I do not see holes. If no holes how is the vacuum getting to the work-piece? Thanks

Hey Rick, the spoilboard that you can see a few posts above is 18mm MDF which was much too thick (though in theory that should not really matter, have to try later) so I bought some 3mm MDF. The MDF is not really dense so the air can flow through it (even more if you plane down the top 0.1mm which I didn’t do yet). So the MDF is sitting directly on top of the grid I milled and made airtight, the workpiece on top the MDF.

Oh so no holes? I would not have guessed that worked due to the glue. Very interesting.

It works really, really well. If you have 3mm MDF at home, press it to your mouth and try breathing through it. It kinda works. If you plane down the top and bottom (which is compressed the most) the airflow is even better.

Next up is still the insulation and maybe another vacuum pump. I am not sure about this though, want to do a few test-cuts first.

The upper thin MDF acts as an air porous vacuum, without needing to drill additional holes ![]() ? Neat.

? Neat.

Guessing some of the suction lost around the perimeter of the stock can be reduced by covering with scrap wood/paper?

lol, I believe you, and will not verify, https://www.google.com/search?q=mdf+cancer

Yeah, it was the very first test. If I painted the edges of the spoilboard as well less air would be lost there. I guess it will be working well for larger pieces, smaller pieces not so much because as soon as you cut through the stock there will be a non-suction area at the boarder of the workpiece, the smaller it gets the less suction is there. Tests will show. ![]()

“Prolonged exposure to formaldehyde can result in cancer”. ![]()

There is also an ultra light DF, can’t get that in Germany though, which has 40% less glue. Is obviously supposed to be working better still.

Porous substrate has been used as a vacuum manifold in industry for a long time

Here’s a link to two experts using it to lift a car

You are 9 days late. ![]()