I’m aware that it’s generally very ductile, but supposedly nylon CF ends up as the best of both worlds. I think my biggest concern is that it may soften due to hygroscopy.

Hydroscopy is definitely a factor. I’ve wanted to try the PA11 from Prusa and see how it does. Supposedly less so.

But really, the only thing you are gaining over pure PLA is heat resistance. If curious, all you can do is do some test yourself. I think you’ll find it’s hard to beat PLA no matter what those charts say

I should add…I was asking all these same questions before I built mine. I wanted to find the “best” filament and decided the only way to get there was do the tests myself on the filaments I was interested in. I would have used ANY filament at any cost (well mostly anyway) and after hours and hours of testing ended right back at PLA.

Yes 3DXTech is all I use when it comes to the engineering type materials. Worth the cost. And you’re right about the moisture content. PC, PA and even PETG need to be dry, dry dry. If you don’t have a way to dry and keep them dry don’t even bother experimenting with them - even if your going to use them right out of the bag brand new.

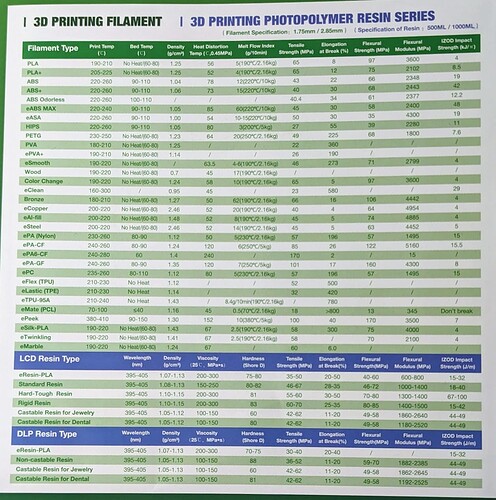

FWIW, here’s the material properties comparison sheet for eSUN. I couldn’t find it on their site, but it’s included in the box with each roll from them and I didn’t notice it until recently.

I would be curious to see how onyx or any other CF filled nylon performs when printed at a higher infill. The Markforged printer uses a proprietary slicer that encrypts the gcode, the proprietary slicer only lets you go up to 38% infill.

![]() Thats me! Other than the core, I printed that on an SLA printer out of a ceramic filled resin and the core is awesome.

Thats me! Other than the core, I printed that on an SLA printer out of a ceramic filled resin and the core is awesome.