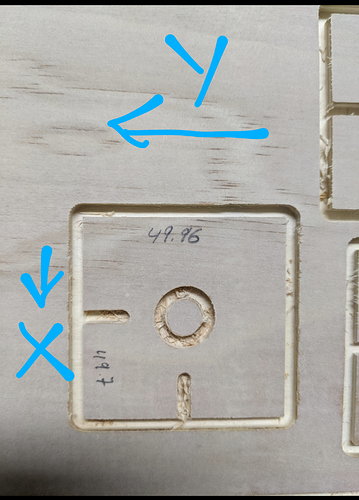

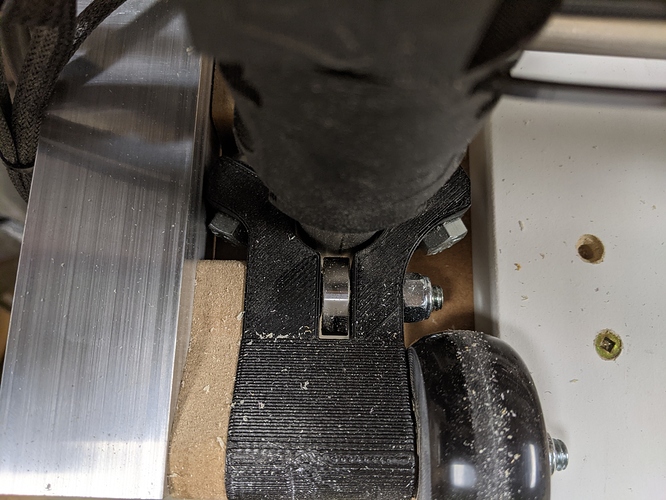

Well I hate to jump the gun because tomorrow everything might be different but tonight I think I solved it. I was looking at everything closely and noticed when I moved the gantry in the Y direction with steppers locked the Y plates would flex (toe in and toe out). Grabbed some aluminum angle and bolted it across the wheel bolts and the Z axis bearing bolts. Surprisingly this straightened the plate out quite a bit. I went from wheels rubbing on the track to about 1/8" gap. I left the gap at the rails and did a test cut. Y axis now at 49.96mm which I am very happy with. The X dropped a bit but I chock that up to the gap between wheels and rail. I noticed it wandered a little bit. I am done testing for now and will get back to making fun parts. Eventually I might make the Y plates out of something more rigid. One odd thing was that when I put it all together the forward bearing doesn’t touch the Z axis tube even if I tighten it right up. I am mainly doing through cuts so the Z axis is not that critical but I might take it apart again and see what’s going on there.

Boom! good stuff. If that remains consistent at less than 0.1mm I’d say that’s pretty awesome. I wish you luck with the cutting.

Yeah we will see how it stays over the course of a few hours of cutting. I’ll report back after I get my wife’s “to cut” list out of the way.

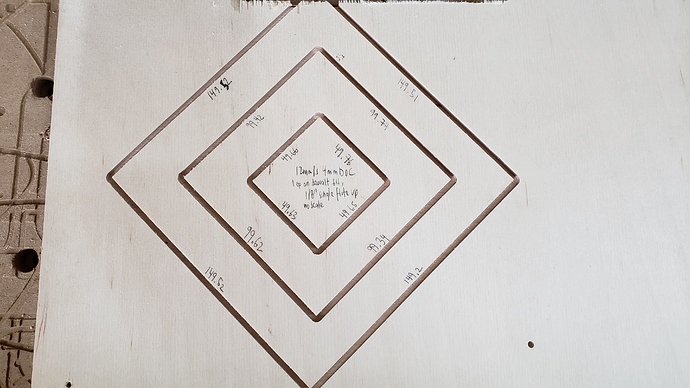

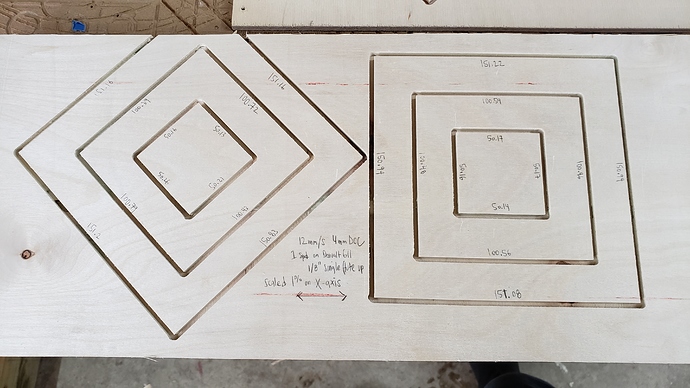

As I was also curious i tried a few myself. Double checked the tight belts and bearings and here we are. 50,100,150mm rectangles, undersized a tiny bit on all with diagonals. With the little one out by .4mm consistently under size but only .13mm between dimensions.

100mm was under as much as .7mm and out by .4mm between dimensions. 150mm was under as much as .8mm but only .3mm between dimensions, 3 of 4 were within .01mm!

The second test i scaled the x axis alone by 1%, which resulted in everything being oversized but it seemed to tighten the consistency. The 50mm was over by .17mm and within .03mm between dimensions. The 100mm was over by .59 but within .11 between dimensions. The 150mm was over by 1.22mm but within .28mm between each side. The diagonal showed similar results.

When you push your gantry do you see the wheels flex in and out?

Also, try a .3mm clean up pass. I saw marginal improvements when switching though. I should get more time on the machine this evening to see if the numbers are still consistent

This included a .3mm finish pass. I can’t see any wheel flex. My y plates are 1/2" lexan so plenty stiff.

It’s interesting to see that your error grows with your size. Almost like it’s going further per rotation then it thinks

I can confirm that hardboard will flex and cause distortions.

The wheels can flex in and out a bit due to weight on the gantry. I’ve noticed many here have added linear guides of one sort or another to aid in tracking straight. I’ve not had this issue though and I don’t know why/how.

How tight is your x axis belt? My guess is people who have problems might have the x axis too tight causing toe in of the y plates. Just an assumption though.

So things are looking better. I seem to have my Y axis dialed in now. When cutting a tab at 80mm I am measuring 80.02mm. Now my X axis is the one that is still a bit out. I think it’s the bearings. It was very very tight getting them on to the z rails so I might recut the 611 plate.