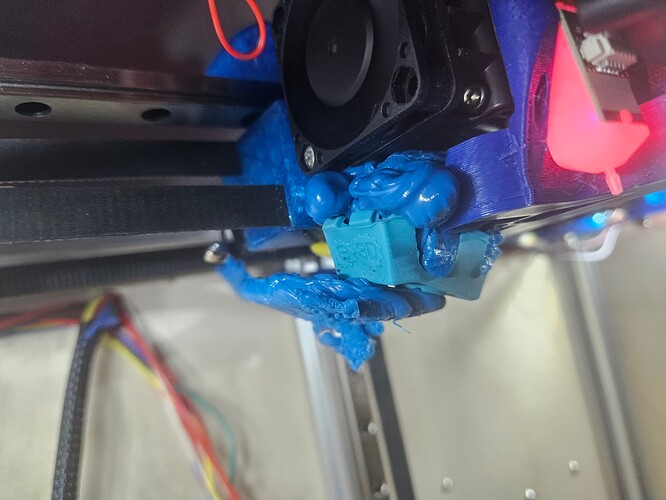

I only made a smiley emoticon reply because there was no crying one! I’ve had one of those - my fault as they always are, in clear and it encapsulated by hotend wiring nicely.

Patience is all it takes to remove it! ![]()

All the best with that.

I stopped using silicone socks for this very reason -_-

One more thing to pick out of the blob?

Not really ![]()

If you cough and throw out a massive booger -contamination concerns apart - would you rather have this happen while wearing a mask and smear it all over your face, or just let it fly? ![]()

When you start to get a blob, the melted plastic tends to balloon in the sock rather than just oozing away

In my experience, with the sock you get more melted plastic, and higher up on the head, which causes the wires to get trapped

Cleaning the Heather block and nozzle is pretty easy, but those thin thermistor wires? ![]()

And even if you don’t break them cleaning it, they get all crispy and rigid ![]()

On my printer I have a whole spare printing head to switch to when this kind of things happen, while I cleanup everything

I have spare printers… but I don’t have an extra Hemera sitting around.

I got the blob off, but the silicone sock is pretty thoroughly turned into an injection mold at this point. Fortunately the wires were mostly spared.

Anyone lightly greasing their printed Core to prevent inevitable blobs sticking, e.g. Silicone grease (I haven’t temp tested this…)?

That’s the one good side of cheap printers… ![]()

Whole printhead: nozzle, Heather, extruder, stepper motor and mount for all of this => 25€

Plus on the artillery X1, swapping out is just 3 screws and a single connector

I wonder about that - the good side of “NOT” cheap printers, is that these sorts of excursions into hell are rare.

I’m not arguing that the additional cost can be justified rationally, but spending twice (or three times?) as much for a tenth of the trouble along the way is an interesting equation to contemplate! ![]()

Not in this instance specifically, but given how much grease can get onto a build plate just by touching it with freshly washed hands, for me it would be opening a monster can of worms.

I would have grease spread everywhere before you could say “but it was just a very slight film”.

AND silicone is forever.

Silicone grease is supposed to tolerste up to 300°C so maybe… but since in this case the problem is that the darn PLA won’t stick to the bed, I do not want to add grease into the equation. What happened here is that I finally got a first layer to stick, but looks like on the third layer, the nozzle picked up the entire print and started dragging it around the bed. I seem to have far fewer problems with PETg, this was with PLA, on a PEI coated spring steel plate. I can get it to stick to painter’s tape, but I don’t like the surface finish. The whole reason for the PEI sheet is so that I don’t need to deal with that.

I’ve scrubbed the PEI with amagic eraser, and I use 99% IPA on it regularly. PETg works fine, but PLA just doesn’t want to. Now I’ve used up my last magic eraser, so I have to go buy more…

I rarely have a problem on a PEI sheet with PLA - when it does happen it takes a bit of persuading things to stay down -

Firstly I clean with pretty much neat dishwashing liquid and a CLEAN microfibre cloth, then rinse with the same cloth under hot running water. Then dry with a CLEAN tea towel.

Mostly that works, but when it is still cantankerous, I give it a rub with IPA and a paper towel. I suspect the paper towel is giving the surface a sub-microscopic scuff.

If that still doesn’t work, I rotate the position of the part by 45-90 degrees. If that still doesn’t work I add a 4mm brim.

After all that it sorts itself out, and I don’t have a problem again for another six or twelve months.

BUT - I do clean my bed after almost every print with IPA and a paper towel. My theory (which is completely made up) is that there’s a sub-microscopic PLA residue that fills the grippy bits in the PEI.

NOTE - I’ve never used tape, glue or hairspray - just persevance when this happens!

Sure, but there’s “cheap” and “dirt cheap” I guess ![]()

My X1 has been running quite fine for the past few years, pretty much no problem appart from the occasional clogged nozzle or worn out bed

Kept it almost stock too, no fancy upgrades…

Print quality is “ok”, far from what an MK4 or bambulab can achieve, but at a fifth of the price that’s not a problem (I’m essentially printing “functional” parts)

In fact I have several heads, one is a spare .6mm , the others are pre-mounted with .4 and .8 nozzles

The funny thing is that the whole head assembly, including motor is cheaper than a single E3D Revo nozzle, and yet it’s almost easier to swap than this…

Why use a complicated and costly swappable nozzle system when you can just swap the whole head just as easily and for the same price…

Not saying higher end solution aren’t good, or not up to the asking price, but sometimes it’s good to remember that simple things just work…

Slice Engineering makes an anti-stick coating that works great for nozzle heads. Probably work for the other metal parts too. Agree with @bitingmidge. Greasing the toolhead might give you more problems.

If you’re really having trouble with adhesion, Vision Miner Nano Polymer has never let me down. It’s worked on everything - Nylon, PC, ABS, - it never fails. I’d even go as far as saying skip Magigoo and go right to the Nano Polymer. Magigoo works most of the time, but when it doesn’t your going to move to Nano Polymer anyways - especially on long prints where failure might cost you a day and a lot of filament. It’s expensive but will last a long time and it’ll be one less thing you have to worry about.

I guess a sock wouldn’t really be needed in all instances. It’s more of a necessity if you print at higher temps, if you’ve got a low wattage heater cartridge, and/or your fan ducts are close to the heater block.

Anyone using Camera + AI software to detect fluff ups? E.g. Obico (formerly known as the Spaghetti Detective), or something similar?

Looking into whether to use separate Pi Zero 2 as an IP camera. Currently running Klipper/MainSail on a Pi 4.

There’s a bunch of options/alternatives…

Personally looking for something that’s fully self hosted.

That’s odd that you’re having that much issue.

For me, when PLA isn’t sticking, it’s because I recently did something with the print head and my babysteps is off. It’s no longer being squished onto the build plate.

I recently got the same blob you did. In my case, the extruder had gotten loose from the core so that it was dangling down. The hot end rubbing across the top of the part I was printing caused it to grab the part and the rest turned into a large booger like yours.

I was able to heat the nozzle to 170c and then peal the entire blob off the printer.

closing old topic to help fight spambots