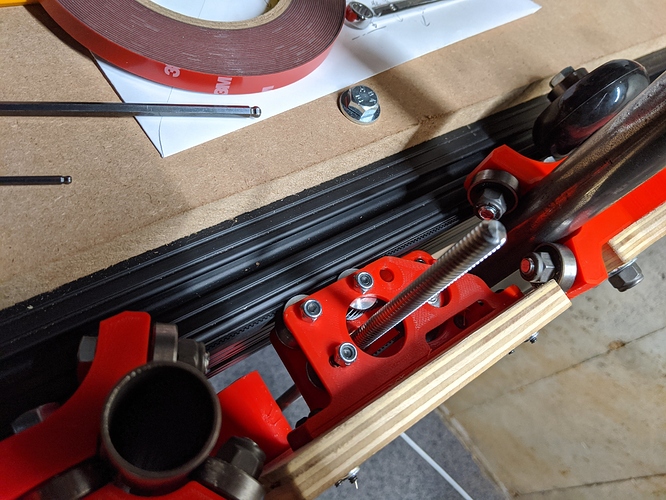

from what I’ve read, the tension only matters in the section between the two roller wheels and the motor, which is why it should work well (only a small section to stretch). I ended up using 3M VHB 10mm tape, and put some mild tension on the belt while laying it down. It’s mostly together and meshed, but my tension pulley needs some work. It has to work almost twice as hard because it has 120deg of wrap, and when I tighten it down it locks up.

One other factor in this design is that the belt sags a bit… usually it’s on the top side and gravity helps it stay in place. The pulley seems to keep it aligned once it meshes.