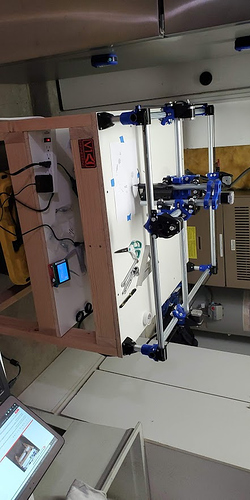

2x4 and 4x4 my avatar was cut on MPCNC

My plan was to be able to engrave on a 2x4/2x6. I can do that so I guess I am good

Biggest thing to keep an eye on is making sure your Z tubes clear any 3d relief cutting you do. Ended up not finishing a 3d relief of a face because the tubes about hit the end of the nose. Still had a half inch to go! Even the roughing pass looked cool though.

If you keep your z tubes above the bottom of your collet it should always be able to clear your work. I have mine closer to the top of my collet, which needs longer z tubes but less chance of collisions.

Do you think I should go with 4" so I have that extra distance? I was planning on using a 1/2" spoil board on top of the table like what you mentioned.

Yeah, you can always cut them shorter. Or you might have extra lengths left over from your cuts enough to make two sets, one 3" and one 4".

What’s your machine’s Zheight?

At that time it was around 4 inches. It’s not a machine height issue, it’s an endmill length issue.

Side question: What are your favorite bits to work with?

I saw the bundle that Ryan sells in the store and I was going to start with that. They’re all 1/8" bits and I’ve heard some like 1/4in" but I’m still trying to learn more about them.

I have not personally purchased Ryan’s because I am in Canada and shipping on a small order is painful.

However, as I understand it, most people are happy with that variety pack and recommend it. As a new person to the MPCNC here are my quick comments on bits. These are the order that I discovered them in:

1/8" Up-Cut Bit

This worked great for me and was what I started with. It could do decent detail and nice pocketing.

1/4" Up-Cut Bit

I got this because I just wanted to try something bigger and because I was making a spoil-board that had like 80 1/4" holes. This bit is good/great but you cannot do much detail work with it. Hence, work pieces have to be bigger cause fonts/words have to be bigger.

90 Degree V-Bit

This is also an amazing bit. You can do finer detail because the DOC affects how wide the cut is. Small pockets work okay for me.

Hope that helps.

I like 45 and 60 degrees v bits for text and some carving

Most deep pocketing and cutout use 1/4 inch 1 flute.

For detail pocketing I use 1mm 2 flute.

I also have 1 inch bed flattening bit

Plus a lot ok f others not used a lot

The sharper bits (45 is sharper than 60 is sharper than 90), will have less width error when they have error in Z. Which is why Ryan recommends the sharper ones. Less fuss on the Z getting it perfectly flat.

Thanks everyone for the advice and help! I started the build last night and I’m 14hrs away from the final printed part!

Im pretty sure by Saturday I’ll at least have it moving and maybe by next weekend I’ll have my first cut if everything goes well!

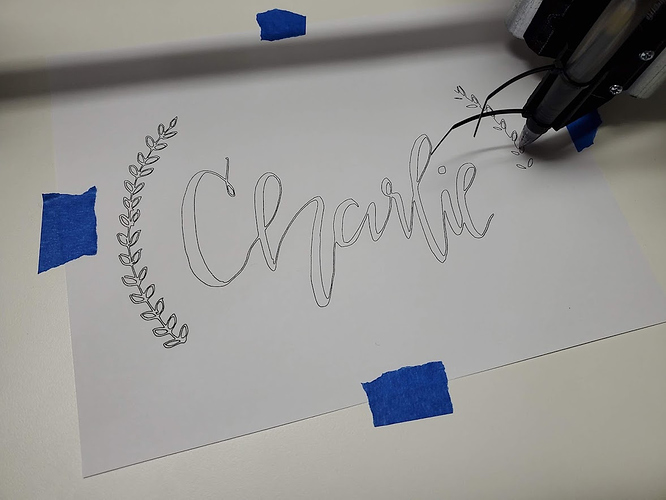

Its done! I built it all up today and got my first couple drawings!

I even figured out how to convert some of my wife’s Instagram photos into vector files so I’ll eventually be able to carve them out of wood!

Just got my shipment of endmills today so I’m just waiting for the DW660 to come in on Tuesday for the first cut! So excited!

Where did you get your bits from? I’ve been looking around ebay and other website but I’m not sure where to start

https://www.ebay.com/sch/drillman1/m.html

Is where I get stuff not from Ryan.

Thanks! Appreciate the help

Try to stick to one and two flute endmills. They work the best for our routers.